Warning. In order to prevent damage to the box mounting supports, the connections are in the places marked «*» in figures 12.22 and 12.23 should be pre-tightened, and the final tightening should be done after the engine is lowered onto the supports.

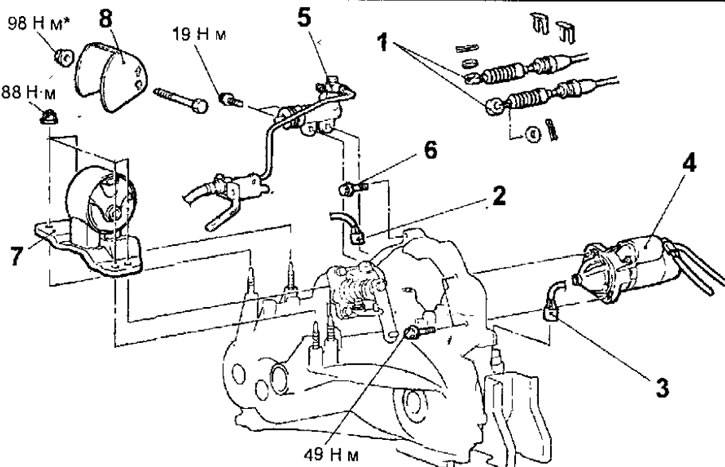

Pic. 12.22. Gearbox mounting elements F5M42: 1 - tips of cables for selecting and shifting gears; 2 - reversing light switch connector; 3 - vehicle speed sensor connector; 4 - starter; 5 - clutch slave cylinder; 6 - upper bolts for fastening the gearbox to the cylinder block, 48 N-M; 7 - gearbox support bracket; 8 - Gearbox support stopper

Removing

- Disconnect the wire from the negative battery terminal.

- Drain the gear oil from the gearbox.

- Remove the lower engine mudguard.

- Remove the air filter assembly.

- Remove the battery and its support.

- Remove the fuel vapor canister.

- Remove the cotter pins and disconnect the select and shift cables from the gearbox (pic. 12.22).

- Disconnect the connectors from the reversing light switch and vehicle speed sensor.

- Unscrew the bolts and remove the starter and, without disconnecting the wires from it, fix it in a place where it will not interfere with the removal of the gearbox.

- Remove the clutch slave cylinder and, without disconnecting the hose from it, fix it in a place where it will not interfere with the removal of the gearbox.

- Turn out the top bolts of fastening of a transmission to the block of cylinders.

- Carefully lift the transmission with a hydraulic jack, then loosen the nut, remove the bolt, remove the transmission retaining flanges and disconnect the transmission support bracket.

- To support the engine, install a special tool on the car (motor hoist with manual hoist and traverse) (see fig. 12.17).

- Raise the car on a lift.

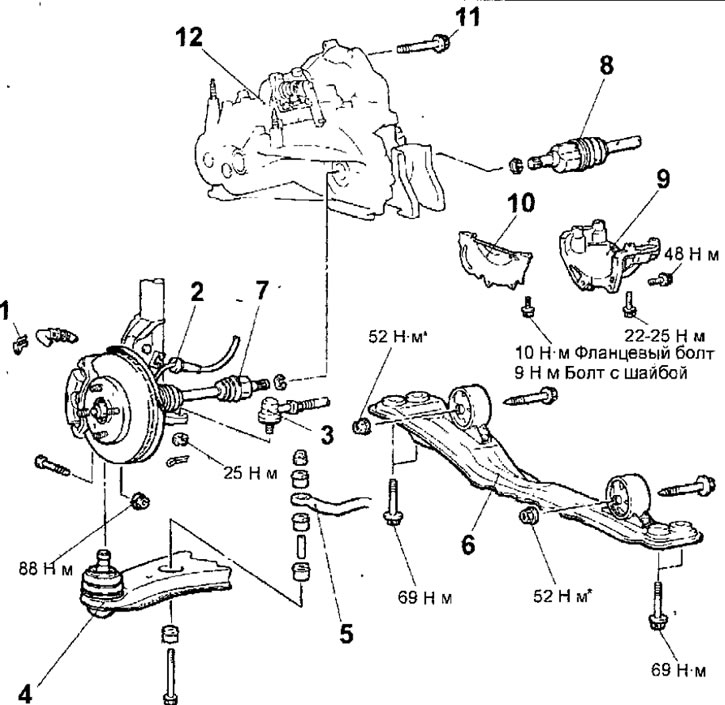

- Remove the retainer securing the brake hose to the front suspension strut (pic. 12.23).

- On a vehicle with ABS, disconnect the connector from the wheel speed sensor.

- Remove the cotter pin and loosen the nut securing the ball joint pin of the tie rod end to the steering knuckle.

Pic. 12.23. Gearbox mounting elements F5M42: 1 - brake hose retainer; 2 - wheel speed sensor connector (cars with ABS); 3- ball joint of the tie rod end; 4-ball joint lower arm; 5 - anti-roll bar; 6 - central beam assembly, 7 - left drive shaft; 8 - right drive shaft; 9 - gearbox support; 10-front cover of the clutch housing; 11 - lower gearbox mounting bolts, 48 Nm; 12 - gearbox

Warnings. Do not loosen the nut securing the ball joint pin of the tie rod end to the steering knuckle. To prevent damage to the threads on the ball joint pin, use the special tool MB991113 or MB990635.

- To prevent falling of the special tool MB991113 or MB990635, fix it with a cord on the front suspension strut.

- Install special tool MB991113 or MB990635 as shown in figure 12.19, while making sure that the jaws of the tool are parallel. Turn the special tool bolt to push the ball joint pin out of the steering knuckle, then loosen the nut and remove the ball joint pin from the steering knuckle.

- Loosen the nut, remove the bolt and lower arm ball joint pin from the steering knuckle.

- Turn away nuts and get bolts of fastening of the antiroll bar to the bottom levers, turn out bolts and remove clips of fastening of the antiroll bar, then remove the stabilizer from the car.

- Turn away nuts, get bolts and remove the central beam in gathering.

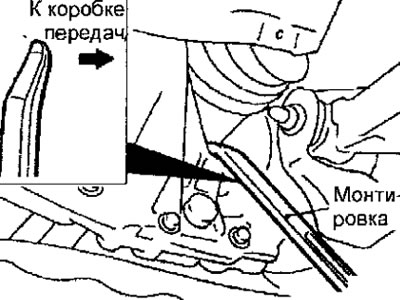

- Insert a pry bar between the driveshaft inner CV joint and the gearbox and tap lightly on the pry bar to remove the driveshaft from the gearbox (pic. 12.24).

Pic. 12.24. Using a pry bar to remove the drive shaft from the gearbox

Warnings!

- Use the pry bar very carefully so as not to damage the hinge and the gearbox housing.

- Do not insert the pry bar very deep, so as not to damage the differential seal.

- Do not pull on the drive shaft as this will damage the constant velocity joints.

- Together with the hub and steering knuckle, remove the drive shaft from the gearbox.

Warning. Do not disconnect the drive shaft from the steering knuckle and hub.

- Use a soft wire to secure the removed drive shafts inside the wheel arches so as not to allow the CV joints to be strongly bent.

- Install special plugs instead of drive shafts so that dirt does not get into the gearbox.

Warning. Replace the differential seal each time the drive shaft is removed.

- Turn out bolts and remove a support of a transmission.

- Turn out bolts and remove a forward cover of a case of coupling.

- Turn out the bottom bolts of fastening of a transmission to the block of cylinders.

Warning. When separating the gearbox from the engine, be careful not to damage the gearbox input shaft, clutch release bearing guide bush, and clutch disc.

- Pull the gearbox away from the engine and remove it from the vehicle.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- Install the stabilizer bar and tighten the self-locking nut so that the stabilizer mounting bolt protrudes above the nut as shown in Figure 12.21.

- Install the gearbox stopper so that the arrow on the flange points in the direction shown in Figure 12.25.

Pic. 12.25. Installing the gearbox retaining flange

- Connect the selector and shift cables to the gearbox and secure them with cotter pins.

- Install adsorber.

- Install the battery.

- Install the air filter assembly.

- Install the lower protective cover.

- Fill the gearbox with gear oil.

- Check up smoothness and correctness of movement of the lever of a gear change in all positions.

- Check the operation of the speedometer.