Note. On vehicles with engines 4G93, F9Q1 since 2000, instead of the adjusting bolt, a clutch pedal position switch is installed.

Removing

- On a left-hand drive vehicle, remove the relay box and activated charcoal canister.

- Remove the clutch master cylinder nut (pic. 11.6).

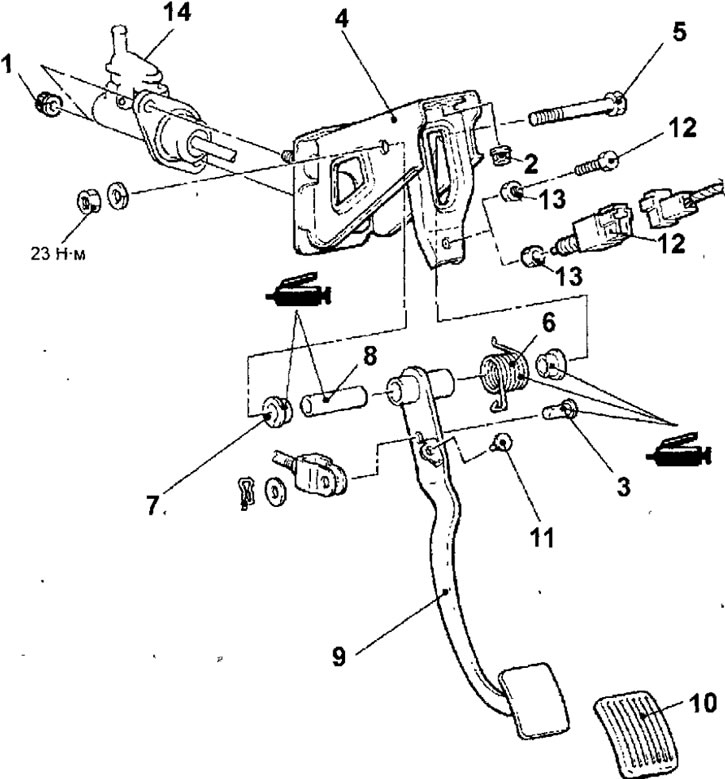

Pic. 11.6. Clutch pedal: 1 - nut of fastening of the main cylinder, 13 Nm; 2 - nut, 25 Nm; 3 - pin; 4 - clutch pedal bracket; 5 - bolt; 6 - return spring; 7 - clutch pedal bushing; 8 - tube; 9 - clutch pedal; 10 - rubber pad of the clutch pedal; 11 - emphasis; 12 - adjusting bolt or clutch release sensor, 13 Nm; 13 - locknut, 13 Nm; 14 - clutch master cylinder

- Loosen the clutch master cylinder bracket nut.

- Remove the cotter pin, washer and pin securing the clutch cylinder pushrod to the clutch pedal.

- Remove the pedal bracket and clutch pedal assembly.

- Turn away a nut and take a bolt of fastening of a pedal of coupling to an arm.

- Remove return spring.

- Remove the bushing from the clutch pedal tube.

- Remove the clutch pedal tube.

- Remove the clutch pedal from the bracket.

- Remove the rubber pad from the clutch pedal.

- Remove the emphasis.

- Loosen the locknut and remove the adjusting bolt or the clutch release switch.

Examination

- Check the pedal arm and bushing for wear.

- Check the clutch pedal for bending or deformation.

- Check the return spring for damage and loss of elasticity.

- Check the clutch pedal pad for damage or wear.

- Clutch Pedal Position Switch Test

1. Connect an ohmmeter to the clutch pedal position switch connector pins (pic. 11.7).

Pic. 11.7. Clutch Pedal Position Switch Test

2. The clutch pedal position switch is operational if, when the sensor rod is extended less than 4 mm from the end of the sensor housing, the circuit is open, and when the rod is extended more than 4 mm, the circuit is closed.

Installation

- Installation is carried out in the reverse order of removal.

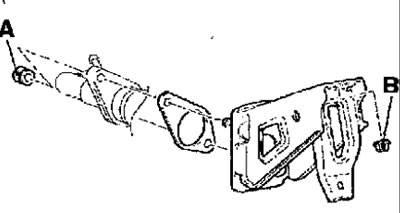

- On vehicles with 4G93 and F9Q1 engines since 2000, tighten nut A first (pic. 11.8) fastening the clutch master cylinder, and then nuts B fastening the pedal bracket. The pedal bracket cannot be installed correctly if the fixing nuts B are first tightened. This is because the stud holes in the bracket are oval.

Pic. 11.8. The sequence of tightening the nuts of the master cylinder (A) and pedal bracket (IN) clutches on vehicles with 4G93 and F9Q1 engines since 2000

- Lubricate the pushrod of the clutch slave cylinder with grease before installing.

- Lubricate bushing, pin, washer and pin before installation.

- Pour brake fluid into the clutch hydraulic actuator and remove air from it.

- Adjust the position of the clutch pedal.