| Code | Malfunction |

| 11 | Throttle position sensor circuit short |

| 12 | Open circuit throttle position sensor. |

| 14 | Throttle Position Sensor Inconsistency |

| 15 | Transmission Fluid Temperature Sensor Circuit Open |

| 21 | Open circuit of the crankshaft angle sensor |

| 22 | Short circuit / open circuit of the input shaft sensor |

| 23 | Short circuit / open circuit of the output shaft sensor |

| 25 | Short circuit of the full throttle sensor circuit |

| 26 | Damage to the brake light switch circuit |

| 31 | Damage to the low gear and reverse solenoid valve circuit |

| 32 | Downshift Solenoid Circuit Damage |

| 33 | Damage to the target of the second gear solenoid valve |

| 34 | Damage to the purpose of the overdrive solenoid valve |

| 36 | Damage to the clutch damper solenoid valve circuit |

| 41 | 1st gear ratio out of specification |

| 42 | 2nd gear ratio out of specification |

| 43 | 3rd gear ratio out of specification |

| 44 | 4th gear ratio out of specification |

| 46 | Reverse gear ratio out of specification |

| 51 | Malfunction of communication with the electronic control unit |

| 52 | Defective clutch damper solenoid valve |

| 54 | Short circuit on «mass» / open circuit of the automatic transmission control relay |

| 56 | Short circuit on «mass» control lamp of position N of the lever of the selector of an automatic transmission |

1. Make a trip to warm up the gearbox to a temperature of 70-80°C.

Note

- 1) Measure transmission fluid temperature with MUT-II.

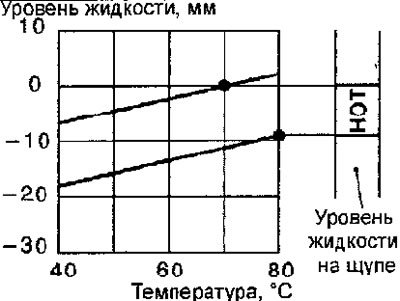

- 2) Referring to the diagram shown in Figure 13.8, determine the level of transmission fluid, as it will take some time to warm up the fluid to a temperature of 70-80°C.

Pic. 13.8. Transmission Fluid Level vs. Temperature Diagram

2. Park the vehicle on a flat, level surface.

3. With the engine running, move the selector lever from position N to all positions and back to position N.

4. Before removing the dipstick, clean the area around the dipstick to remove dirt. Remove the dipstick and check the condition of the transmission fluid. Check the color of the fluid in the automatic transmission. Check the automatic transmission fluid for unusual odors. Compare the fluid with fresh fluid to determine the change in color and odor of the fluid.

Note. If the automatic transmission fluid has a burnt odor or is contaminated with bushing material or friction, the transmission may need to be overhauled and the heat exchanger and tubes flushed.

5. Check the fluid level, which should be between the HOT marks (pic. 13.9). If necessary, add the required amount of the required liquid. A low fluid level can cause many problems as air enters the fluid and the air-liquid mixture becomes compressible, resulting in erratic pressure changes and failure of clutches and band brakes. Also, an elevated fluid level causes the rotating gears of the transmission to whip up foam, which has the same results as air trapped in the transmission fluid. In any case, air bubbles lead to overheating and oxidation of the transmission fluid, which, getting into the valves, disrupts the operation of the clutch and brakes. Foaming may cause fluid to leak out, which may be mistaken for a fluid leak.

Pic. 13.9. The location of the HOT marks on the dipstick for checking the level of transmission fluid

Transmission Fluid: Dia Queen ATF SP II M or ATF SP III

6. Insert the transmission fluid dipstick securely.