DOHC engine (GDI)

Warnings

- 1. Do not adjust the electrode gap of spark plugs with iridium electrodes.

- 2. Cleaning spark plugs can damage the iridium electrodes. Therefore, if cleaning is necessary due to heavy soot deposits, use a spark plug cleaner and do not clean the spark plug. ignition for more than 20 seconds. Do not use a wire brush to clean spark plugs.

- 3. Spark plugs in GDI engines with iridium electrodes may work properly even if they are covered with a layer of soot. Carbon (soot), located on the electrodes, burns out with greater intensity than on conventional candles, and should not lead to problems during engine operation.

1. Remove ignition coils.

2. Clean the spark plugs with compressed air, which will prevent dirt from entering the engine cylinders after unscrewing the spark plugs. Unscrew the candle with a candle wrench. To prevent damage to the candle, install the candle key strictly along the axis of the candle.

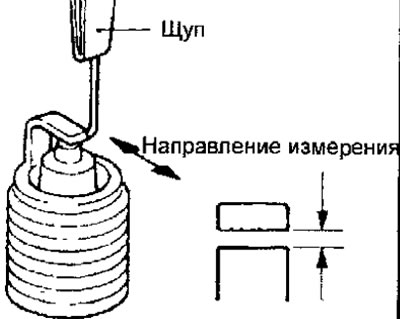

3. Use a spark plug probe to check the gap between the spark plug electrodes (pic. 9.5). The gap must always comply with the technical requirements.

Pic. 9.5. Checking the gap between the electrodes of the spark plug

Interelectrode gap of the spark plug; 0.5-0.6mm

Maximum allowable gap: 0.75 mm

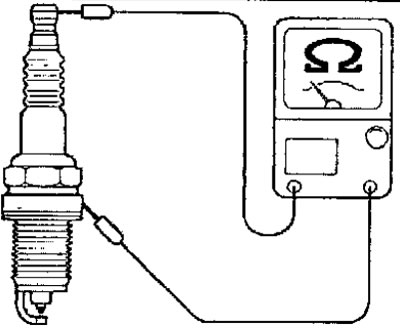

4. Measure the insulation resistance of the spark plug (pic. 9.6). If the resistance is lower than required, replace the spark plug.

Resistance: 1MΩ

Pic. 9.6. Checking the insulation resistance of the spark plug

5. Clean the spark plug holes.

Warning. Be careful not to let foreign particles get inside the cylinder.

6. Screw in the spark plugs.

7. Install ignition coils.

SOHC engine (MPI)

1. Disconnect high voltage wires from spark plugs.

Warning. When disconnecting the tip of the high-voltage wire from the spark plug, do not pull on the wire, but only on the tip, while turning the tip half a turn in one direction and the other.

2. Clean the spark plugs with compressed air, which will prevent dirt from entering the engine cylinders after unscrewing the spark plugs. Unscrew the candle with a candle wrench. To prevent damage to the candle, install the candle key strictly along the axis of the candle.

3. Check for burnt electrodes or damage to the spark plug insulator.

4. Remove carbon deposits with a steel brush or spark plug cleaner. After cleaning, clean the candles from sand, blow them with compressed air.

5. Use a spark plug probe to check the gap between the spark plug electrodes (pic. 9.5). The gap must always comply with the technical requirements. The gap is adjusted by bending the side electrode. In no case should the central electrode be bent, as this can lead to breakage of the insulator and failure of the candle. For bending the side electrode of the candle, you must use a special tool.

Interelectrode gap of the spark plug: 1.0-1.1 mm

6. Clean the spark plug holes.

Warning. Be careful not to let foreign particles get inside the cylinder.

7. Screw in the spark plugs