Checking the primary winding of the ignition coil and power transistor (GDI and 4G13-MPI)

1. Use an analog tester to test.

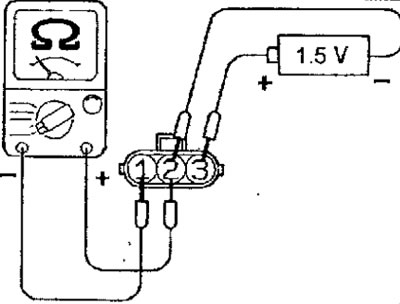

2. Connect the negative probe of the device to pin 1 of the ignition distributor connector, and the positive probe to pin 2 of the connector (pic. 9.3).

Pic. 9.3. Checking the primary winding of the ignition coil and power transistor

Warning. This check must be completed within 10 seconds, otherwise the ignition coil winding may burn out and the power transistor may be damaged.

3. Connect the positive pole of the 1.5 V power supply to pin 3 of the ignition distributor connector, and the negative pole of the power source to pin 2 of the connector, while the device should show the flow of current, and when the power source is disconnected, the device should not show the flow of current (see fig. 9.3).

4. If the test results do not give a positive result, replace the power transistor.

Checking the secondary winding of the ignition coil (GDI)

It is not possible to check the resistance of the secondary winding of this ignition coil, since a diode is built into the secondary winding circuit. Therefore, check the secondary winding as follows.

1. Disconnect the connector from the ignition coil.

2. Remove the ignition coil and connect a new spark plug to the ignition coil.

3. Connect the connector to the ignition coil.

4. Connect the spark plug housing to «weight» and turn the crankshaft of the engine with a starter.

5. Check for sparking between the spark plug electrodes.

6. If there is no spark, replace the ignition coil and recheck.

7. If sparking is observed after using a new ignition coil, then the removed ignition coil is defective and must be replaced.

If there is no spark when using a new ignition coil, the ignition coil circuit may be faulty. Check the ignition circuit.