The knock sensor is screwed all the way into the cylinder block. It reacts to the high-frequency vibrations of the cylinder block that occur during detonation and transforms them into electrical signals to the control unit.

Removing

DOHC engine

- Turn out bolts and remove an engine cover.

- Remove the air filter.

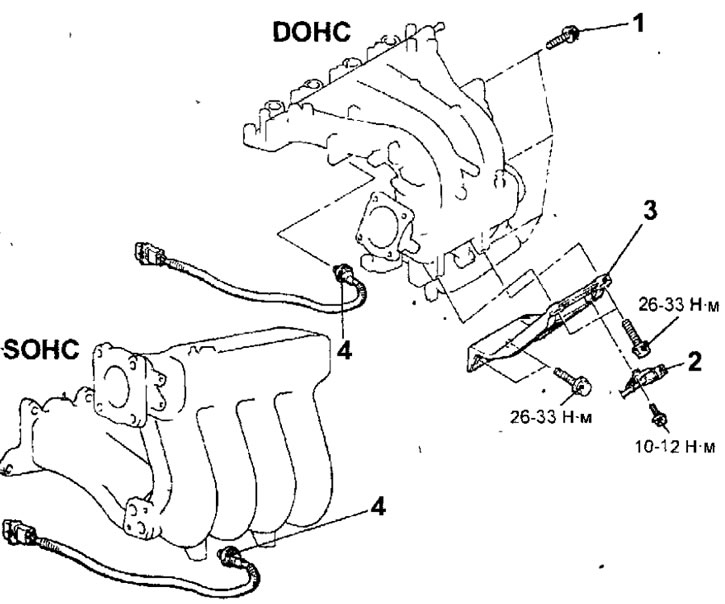

- Turn out bolts and remove the resonator and an arm of the vacuum reservoir in gathering (pic. 9.22).

Pic. 9.22. Engine Knock Sensor DDHC (4G9): 1 - resonator mounting bolt, 9 Nm; 2 - clamp for fastening the connector of the wires of the oxygen concentration sensor; 3 - intake manifold support; 4 - knock sensor, 22 Nm

- Turn out a bolt and remove a clip of fastening of a socket of wires of the sensor of concentration of oxygen.

All engines

- Turn out bolts and remove a support of an inlet collector.

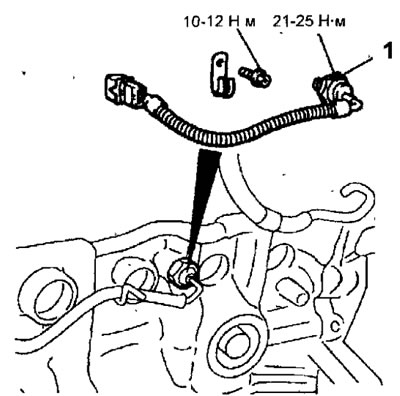

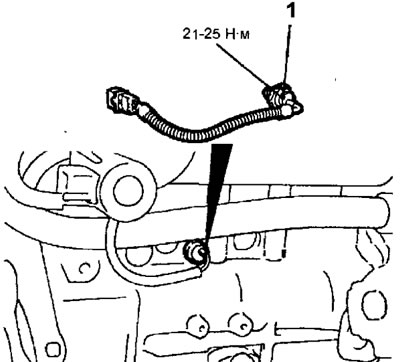

- Disconnect the connector from the knock sensor (pic. 9.20, 9.21).

Pic. 9.20. Knock sensor (1) DOHC engine (4G93-GDI)

Pic. 9.21. Knock sensor (1) SOHC engine (4G13-MPI)

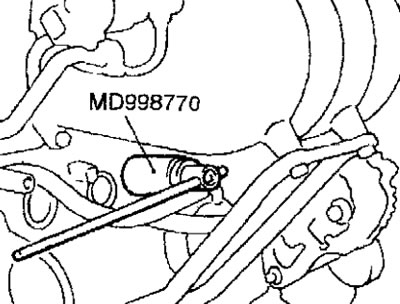

- Remove the knock sensor from the cylinder block (pic. 9.23).

Pic. 9.23. Removing the knock sensor from the cylinder block

Installation

- Installation is carried out in the reverse order of removal.