Removing

- Reduce the pressure in the fuel system.

Warning. Before disconnecting the fuel lines, reduce the pressure in the fuel system, otherwise pressurized fuel will flow rapidly from the fuel system.

- Turn out bolts and remove an engine cover.

- Remove the air filter.

- Remove the throttle body.

- Remove the intake manifold.

- Loosen the clamps and disconnect the fuel return hoses (pic. 6.40).

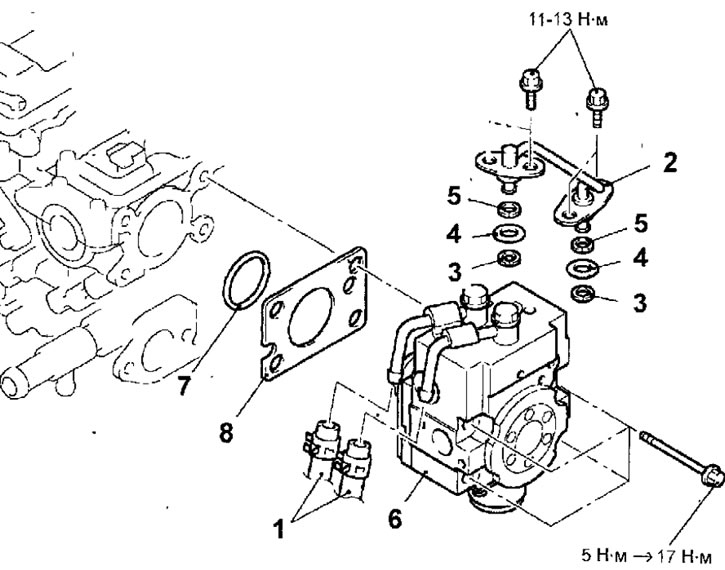

Pic. 6.40. High pressure fuel pump engine from year 2000: 1 - fuel return hoses; 2 - fuel pipe; 3 - support ring A; 4 - sealing ring; 5 - support ring B; 6 - high pressure fuel pump; 7 - sealing ring; 8 - gasket

- Turn out bolts and remove a fuel tube.

- Turn out bolts and remove the fuel pump of a high pressure, a sealing ring and a lining.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

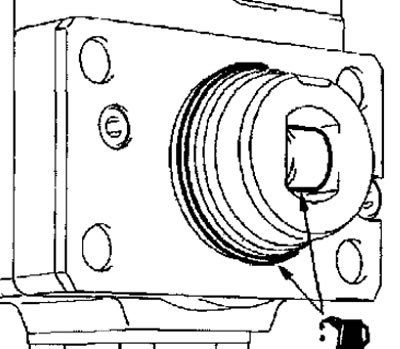

- Before installing the high pressure fuel pump, lubricate the fuel pump roller and o-ring with engine oil (pic. 6.41).

Pic. 6.41. Lubrication points for the roller and O-ring of the fuel pump

- Install the fuel pump to the engine and temporarily secure with the bolts finger-tight. The final tightening of the bolts must be carried out later.

- Install the back-up rings and o-ring as shown in Figure 6.36.

Warnings

- 1. Install support ring B so that the beveled surface of the ring is on the side opposite the O-ring,

- 2. Make sure that the support ring A is installed correctly (the outer diameter of the support ring A is 14.8 mm). Do not confuse it with the pressure sensor support ring.

- When installing the fuel pipes, lubricate the O-ring with a small amount of engine oil.

Warning. Do not allow oil to enter the fuel pump, fuel pressure regulator and fuel line.

- Install the fuel pipe in the fuel pump and fuel line channels and secure with bolts, tightening them to the required torque.

Tightening torque: 11-13 Nm

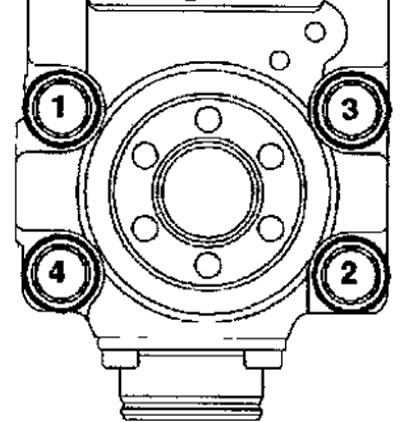

- To tighten the fuel pump mounting bolts, use a torque wrench that tightens to an accuracy of 0.5 Nm. Tighten the fuel pump mounting bolts in the sequence shown in Figure 6.42. in the following way.

1. Tighten the bolts to 5 Nm.

2. Tighten the bolts to 17 Nm. The torque difference between the four bolts must not exceed 2 Nm.

Pic. 6.42. Fuel pump tightening sequence

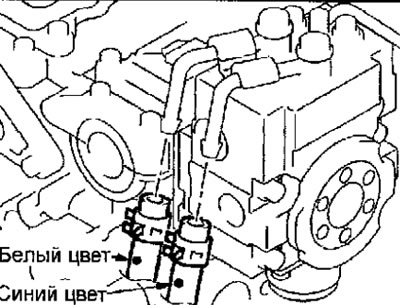

- Install the fuel return hoses so that the marks on the hoses are in the position shown in Figure 6.43.

Pic. 6.43. Installation position of fuel return hoses

Bleeding air from the high pressure fuel pump

- Start the engine and for 15 seconds, leave to run at a crankshaft speed of 2000 min-1, This will bleed air from the fuel pump.

Note. Air can enter the fuel pump when it is removed. If air enters the pump, fault code 56 will be displayed.

- Use the MUT-II to confirm the DTC. If fault code 56 is stored in the memory of the engine control unit, erase it.