Removing

- Reduce the pressure in the fuel system.

- Turn out bolts and remove an engine cover.

- Disconnect the connector from the fuel pressure sensor (pic. 6.49).

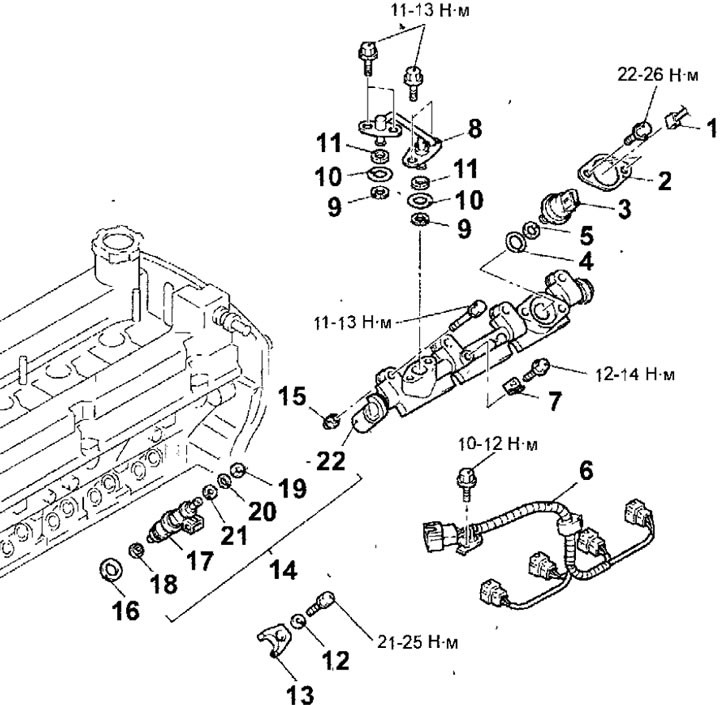

Pic. 6.49. Fuel injectors of the engine since 2000 of release: 1 - fuel pressure sensor connector; 2 - flange; 3 - fuel pressure sensor; 4 - sealing ring; 5 - support ring; 6 - wiring harness for fuel injectors; 7 - bracket for fastening the wiring harness of fuel injectors; 8 - fuel tube; 9 - support ring A; 10 - sealing ring; 11 - support ring B; 12-washer; 13- nozzle holder; 14-fuel distribution line and injectors; 15-support; 16 - nozzle gasket; 17 fuel injector; 18 - curly puck; 19 - support ring A; 20 - sealing ring; 21 - support ring B; 22 - fuel distribution line

- If the fuel pressure sensor will be re-installed, mark and mark the relative position of the flange and the sensor before removing the flange (see fig. 6.34). Turn out bolts and remove a flange of fastening of the gauge of pressure of fuel.

Note. When tightening the flange mounting bolts, the flange is deformed, as a result of which the sealing condition and the installation position of the sensor will be maintained in good condition. Therefore, it is necessary to apply alignment marks in order to install the flange and the sensor in the original position. When replacing the fuel pressure sensor, also replace the flange.

- Remove the fuel pressure sensor.

- Remove the air filter.

- Remove the intake manifold.

- Remove the throttle body.

- Turn out a bolt and remove an arm of fastening of a plait of wires of fuel atomizers. Disconnect the connectors and remove the fuel injector wiring harness.

- Turn out bolts and remove a fuel tube.

- Unscrew the shavers, remove the washers and nozzle holders.

- Turn out bolts and remove a fuel distributive highway together with atomizers established on it. Be careful not to drop the injectors when removing the fuel rail.

- Carefully remove the fuel injectors from the fuel distribution line.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- Install the back-up rings and o-ring on the injector as shown Figure 6.36.

Warnings.

- 1. Install support ring B so that the beveled surface of the ring is on the side opposite the O-ring.

- 2. Make sure that the support ring A is installed correctly (the outer diameter of the support ring A is 14.8 mm). Do not confuse it with the pressure sensor support ring.

- Install the shaped washer on the fuel injector.

Warnings!

- 1. When installing, you must use new shaped washers.

- 2. The surface of the shaped washers must be free of scratches or particles and foreign material.

- 3. When installing shaped washers, strictly observe the installation direction (pic. 6.45).

- To secure the shaped washer to the fuel injector, apply grease to the surface of the shaped washer.

- Lubricate the fuel injector O-rings with a thin coat of engine oil (pic. 6.46).

Warning. At removal and installation of a fuel highway exclude hit in it of engine oil.

- Being careful not to damage the O-ring, turn the fuel injector back and forth into the fuel line and make sure the injector turns easily in its seat.

- If the nozzle turns in its seat with a sticking, it is possible «bitten» sealing ring.

- Remove the fuel injector and check the condition of the O-ring and replace if damaged. Reinstall the fuel injector into the fuel line and recheck that the injector rotates easily in its seat.

- Align the alignment marks of the fuel injector and the fuel line (pic. 6.47).

- Install the injector gaskets and bushings to the cylinder head.

- Install the fuel line with the fuel injectors and secure it with the bolts, hand-tight temporarily.

- Install the nozzle holders and secure with bolts, tightening them to the required torque.

Tightening torque: 21-25 Nm

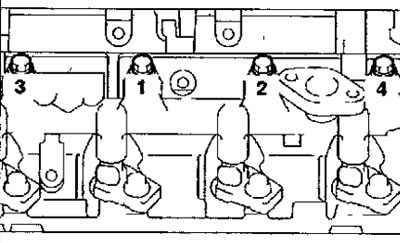

- In the sequence shown in Figure 6.50, tighten the fuel line mounting bolts to the required torque.

Tightening torque: 11-13 Nm

Pic. 6.50. The sequence of tightening the bolts of the fuel line

- Establish support rings and a sealing ring on a fuel tube as it is shown in drawing 6.36.

Warnings!

- 1. Install support ring B so that the beveled surface of the ring is on the side opposite the O-ring.

- 2. Make sure that the support ring A is installed correctly (the outer diameter of the support ring A is 14.8 mm). Do not confuse it with the pressure sensor support ring.

- Lubricate the O-rings of the fuel pipe with engine oil. Do not allow oil to enter the high pressure fuel pump or fuel line.

- Install the fuel pipe and secure with bolts, tightening them to the required torque.

Tightening torque: 11-13 Nm

- Install the support and sealing rings on the fuel pressure sensor, as shown in Figure 6.39.

Warning. Ensure correct installation at the support ring (the outer diameter of the support ring A is 15.1 mm). Do not confuse it with the support ring of the injector, fuel supply pipe and fuel return pipe.

- Lubricate the O-ring of the fuel pressure sensor with engine oil. Do not allow oil to enter the fuel pressure regulator.

- Align the marks made before removing the sensor, and install the fuel pressure sensor and flange on the fuel pressure regulator (pic. 6.51). When replacing the fuel pressure sensor, also replace the flange.

Pic. 6.51 Installing the fuel pressure sensor