Removing

- Reduce the pressure in the fuel system.

- Turn out bolts and remove an engine cover.

- Remove the air filter.

- Remove the intake manifold.

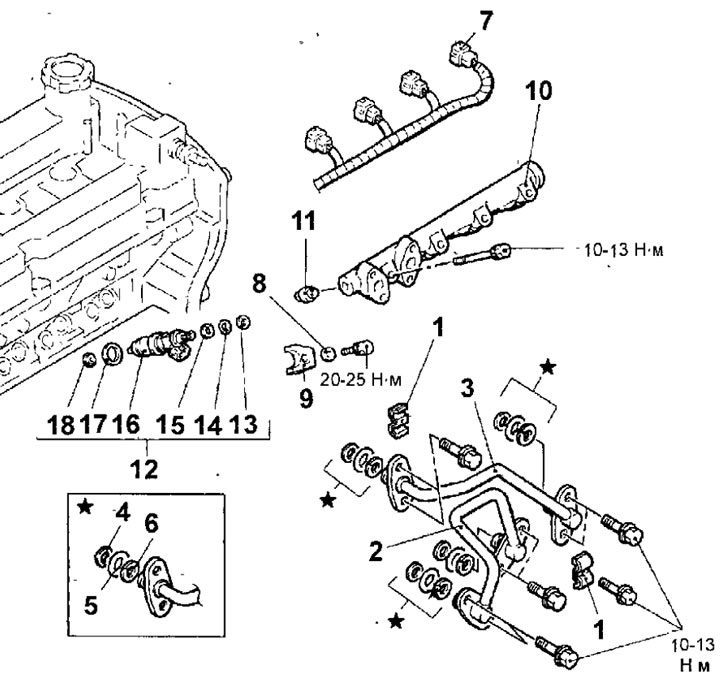

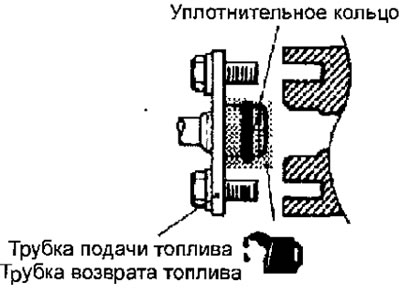

- Turn out bolts and remove clips of fastening of fuel lines (pic. 6.44).

Pic. 6.44. Fuel injectors of the engine since 1999 of release: 1 - clamp for fastening fuel lines; 2 - fuel supply pipe; 3 - Fuel return pipe; 4 - support ring A; 5 - sealing ring; 6 - support ring B; 7 - fuel injector connector; 8 - washer; 9 - nozzle holder; 10 - fuel distribution line; 11 - support; 12 - fuel injector; 13 - support ring; 14 - sealing ring; 15 - support ring; 16 - fuel injector; 17 - gasket; 18 - shaped puck

- Turn out bolts and remove a tube of giving of fuel.

- Turn out bolts and remove a tube of return of fuel.

Warning. Before disconnecting the connectors from the fuel injectors, disconnect the wire from the negative terminal of the battery.

- Disconnect the connectors from the fuel injectors.

- Turn out bolts, remove washers and holders of atomizers.

- Turn out bolts and remove a fuel distributive highway together with atomizers established on it.

Warning. Be careful not to drop the injectors when removing the fuel rail.

- Carefully remove the fuel injectors from the fuel distribution line.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

Warnings

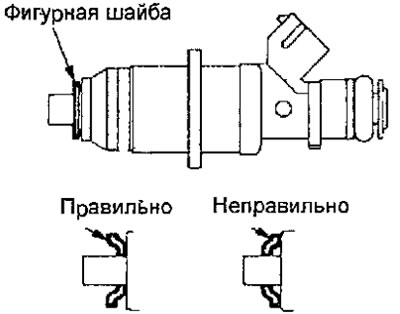

- 1. When installing, you must use new shaped washers.

- 2. The surface of the shaped washers must be free of scratches or particles of foreign material.

- 3. When installing shaped washers, strictly observe the installation direction (pic. 6.45).

Pic. 6.45. Installation direction of the shaped washer on the fuel injector

- To secure the shaped washer to the fuel injector, apply grease to the surface of the shaped washer.

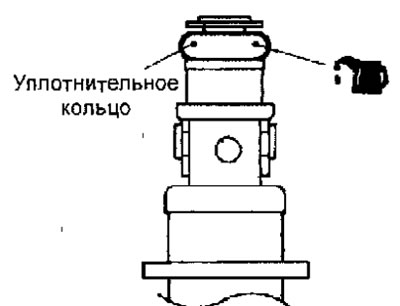

- Lubricate the fuel injector O-rings with a thin coat of engine oil (pic. 6.46).

Pic. 6.46. Location of the O-rings on the fuel injector

Warning. At removal and installation of a fuel highway exclude hit in it of engine oil.

- Being careful not to damage the O-ring, turn the fuel injector back and forth into the fuel line and make sure the injector turns easily in its seat.

- If the nozzle turns in its seat with a sticking, it is possible «bitten» sealing ring. Remove the fuel injector and check the condition of the O-ring and replace if damaged. Reinstall the fuel injector into the fuel line and check that the injector rotates easily in its seat.

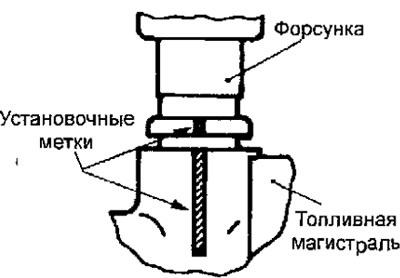

- Align the alignment marks of the fuel injector and the fuel line (pic. 6.47).

Pic. 6.47. Alignment of alignment marks on the fuel injector and fuel line

- Install the fuel line together with the fuel injectors and secure it with bolts, tightening them to the required torque.

- Install the back-up ring and o-ring as shown in Figure 6.36.

Warnings

- 1. Install support ring B so that the beveled surface of the ring is on the side opposite the O-ring.

- 2. Make sure that the support ring A is installed correctly (the outer diameter of the support ring A is 14.8 mm). Do not confuse it with the reference ring of the pressure sensor.

- Lubricate the O-rings of the fuel supply and return pipes with engine oil (pic. 6.48).

Pic. 6.48. Installing fuel supply and return pipes

Warning. Do not allow oil to enter the fuel pressure regulator or fuel line.

- Install the fuel supply and return pipes and secure with bolts, tightening them to the required torque.

- Install the fuel line clamps and secure with bolts, tightening them to the required torque.

- Connect the connectors to the fuel injectors.

- Install the intake manifold.

- Install the air filter.

- Install the engine cover.

- Start the engine and check for fuel leaks from the fuel system.