Warning. Before disconnecting the fuel lines, reduce the pressure in the fuel system, otherwise pressurized fuel will flow rapidly from the fuel system.

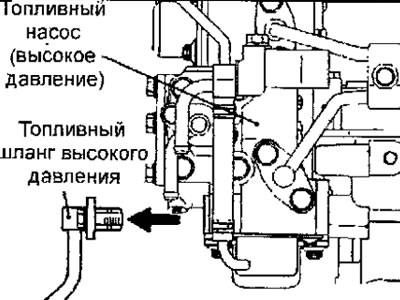

2. Disconnect the high pressure fuel hose from the fuel pump (high pressure side) (pic. 6.11).

Pic. 6.11. The place of disconnection of the high-pressure fuel hose from the fuel pump on a car from 1999 of release

Pic. 6.12. The place of disconnection of the high pressure fuel hose from the fuel pump on a car from 2000 of release

Warning. Use a towel to cover the hose disconnection point, which will prevent splashing of fuel under residual pressure.

3. Unscrew the coupling and bypass bolt from the special tool (adapter hose) and connect the special tool to the adapter hose instead (pic. 6.13).

Pic. 6.13. Assembling Fuel Pressure Instruments

4. Install the assembled special fuel pressure gauge.

When using a fuel pressure sensor (special tool)

- (1) Install special tool (for pressure measurement) between the high pressure fuel hose and the high pressure fuel pump.

- (2) Connect the fuel pressure sensor to the special fuel pressure measuring tool with a gasket between them.

- (3) Connect the fuel pressure sensor wire to a power source (cigarette lighter) and to the MUT-II instrument.

When using a manometer

- (1) Mount the pressure gauge on a special pressure measuring tool with an O-ring or gasket between them (pic. 6.14).

- (2) Install the special tool with gauge assembly between the high pressure fuel hose and the high pressure fuel pump.

Pic. 6.14. Assembly of special tools and pressure gauge for measuring fuel pressure

5. Connect the MUT-II device to a diagnostic socket.

Warning. Switch off the ignition before disconnecting or connecting the MUT-II to prevent damage.

6. Turn the key in the ignition switch to the ON position, but do not start the engine.

7. Select item #07 from the Actuator test menu (Checking actuators) MUT-II to actuate the low pressure fuel pump (from the side of the fuel tank). Make sure there are no leaks at the connections.

8. Disable Actuator test mode (Checking actuators) or turn the key in the ignition switch to the OFF position.

9. Start the engine and let it idle.

10. While the engine is idling, measure the fuel pressure.

Rated pressure: about 324-343kPa

11. Make sure that the fuel pressure at idle does not drop even after several presses on the accelerator pedal.

12. If any fuel pressure is out of tolerance, diagnose and repair according to the fuel system pressure diagnostic chart.

13. Stop the engine and read the fuel pressure on the pressure gauge, which should not change.

If fuel pressure drops significantly after 2 minutes, diagnose and repair according to the Fuel System Pressure Decrease Diagnostic Chart.

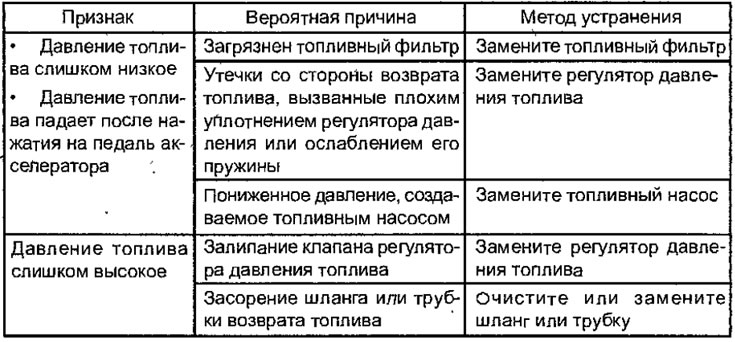

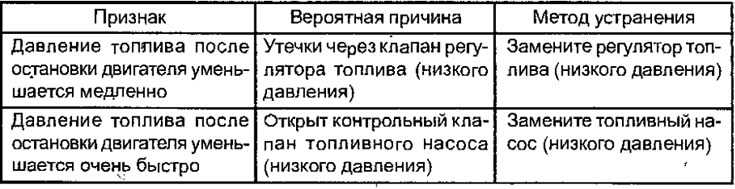

Fuel system pressure diagnostic table

Table for diagnosing pressure reduction in the fuel system

14. Reduce the residual fuel pressure in the fuel system.

15. Remove the manometer and special tools from a distributive fuel highway. Cover the connection with a towel to prevent splashing of fuel caused by residual pressure in the fuel line.

16. Replace the o-ring at the end of the high pressure fuel hose. Before installing the ring, lubricate its surface with a layer of engine oil.

17. Connect the high pressure fuel hose to the fuel distribution line and tighten the flange mounting bolts to the required torque.

18. Check up tightness of fuel system.

19. Disconnect MUT-II from a diagnostic socket.