Removing

- Disconnect the wire from the negative battery terminal.

- Remove the lower engine mudguard.

- Remove the engine mount bracket.

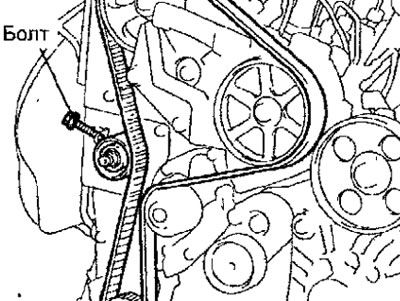

- Turn out a bolt and remove a clamp of fastening of a hose of an air conditioning system (pic. 4.26).

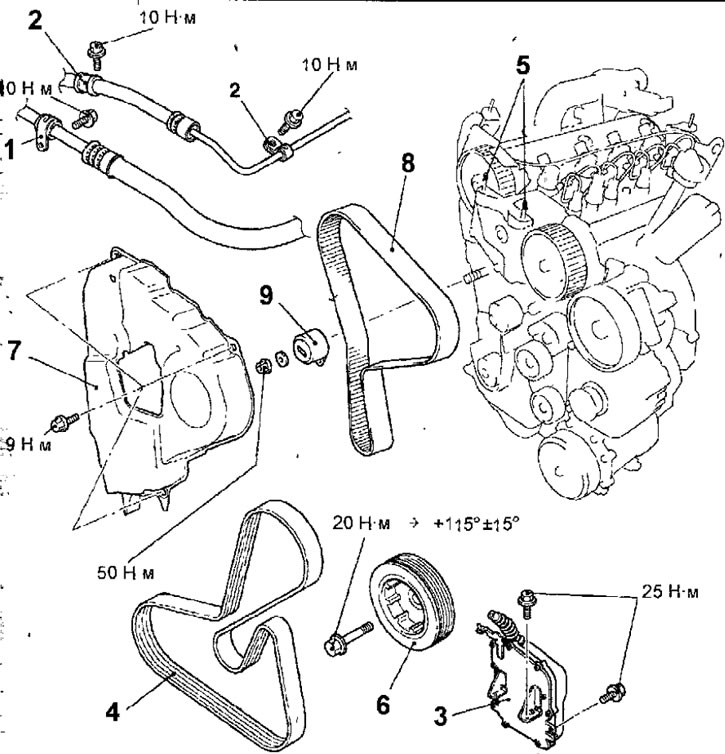

Fig.4.26. Toothed timing belt: 1 - clamp for fastening the hose of the air conditioning system; 2 - a clip of fastening of a hose of a hydraulic drive of the amplifier of a steering; 3 - engine control unit (ECU); 4 - attachment drive belt; 5 - crankshaft pulley; 6 - hairpin; 7 - toothed belt casing; 8 - toothed belt drive timing mechanism; 9 - pulley of the toothed belt tensioner

- Turn out a bolt and remove a clip of fastening of a hose of a hydraulic drive of the amplifier of a steering.

- Turn out bolts and remove the block of management of the engine (ECU) along with wires connected to it. Use a cord or soft wire to secure the removed engine control unit in the engine compartment so that it does not interfere with the removal of the timing belt.

- Loosen the bolt securing the pulley of the automatic attachment drive belt tensioner (see fig. 4.6).

- With a 16mm wrench installed on the tab of the automatic belt tensioner, turn it clockwise, loosen the tension and remove the attachment drive belt (see fig. 4.6).

Warning. Do not reuse a removed implement drive belt.

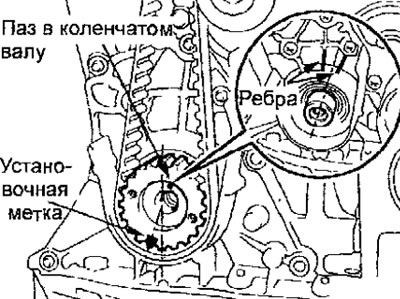

- Turn the crankshaft clockwise until the alignment mark of the camshaft pulley is aligned with the center of the window in the gear housing. belt (pic. 4.27).

Pic. 4.27. Alignment of the timing mark of the camshaft pulley with the center of the window in the toothed belt housing

- Using special tool MD998747, block the crankshaft pulley from turning and remove the pulley mounting bolt (see fig. 4.7).

Warnings!

- 1. If you use the special tool MD998747 to block the crankshaft pulley from turning with the belt installed on the engine, the belt will be damaged. Do not use the original engine attachment drive belt, but use a different belt.

- 2. Never reuse a damaged implement drive belt.

Warning. When loosening the crankshaft pulley bolt, do not rotate the crankshaft or move the alignment mark from the window in the toothed belt housing.

- Remove the pulley from the crankshaft.

- Loosen the nut securing the timing belt tensioner pulley and remove the timing belt (pic. 4.28)

Pic. 4.28. Arrangement of a nut of fastening of a pulley of the mechanism of a tension of a gear belt of a drive of the gas distribution mechanism

Warnings.

- If the timing belt is reused, chalk it on the reverse (not working) side of the belt surface an arrow indicating the direction of rotation of the belt (clockwise).

- Put marks on the camshaft and crankshaft pulleys, as well as on the reverse side of the toothed belt, that determine the relative position of the pulleys.

Examination

- See the corresponding description in the section «4G93 petrol engines».

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- Rotate the crankshaft clockwise and position it so that the crankshaft groove is centered between the two ribs on the front crankshaft cover (pic. 4.29). Also, check that the crankshaft pulley alignment mark is offset one tooth to the left from the vertical line through the center of the crankshaft.

Pic. 4.29. Initial position of the crankshaft before installing the toothed belt

- Make sure the timing mark on the camshaft pulley is aligned with the center of the window in the toothed belt housing (see fig. 4.27).

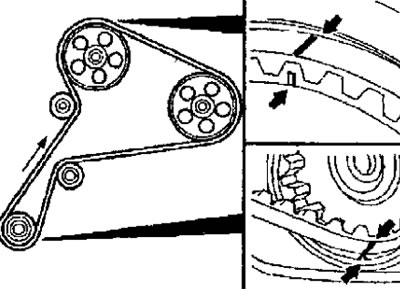

- Install the toothed belt so that the previously applied marks on the crankshaft and camshaft pulleys and on the back of the toothed belt are aligned (pic. 4.30).

Pic. 4.30. Alignment of marks on the crankshaft and camshaft pulleys and on the reverse side of the toothed belt

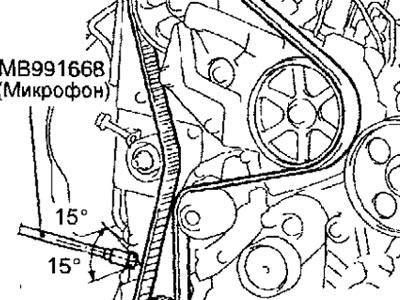

- Position the microphone (MV991668), connected to the MUT-II, perpendicular to the surface of the belt (at an angle of±15°) at a distance approximately equal to 10-20 mm from the back of the belt (pic. 4.31). By turning the M6 bolt, adjust the tension of the timing belt and check that the frequency of the belt oscillations corresponds to the nominal value (pic. 4.32).

Pic. 4.31. The location of the microphone when checking the tension of the toothed timing belt drive

Pic. 4.32. Arrangement of a bolt of adjustment of a tension of a gear belt timing

Timing belt frequency: 90+15Hz

- Using the special tool MD998747, block the crankshaft pulley from turning and tighten the crankshaft pulley bolt to 20 Nm, then tighten by an angle of 115°+ 15° (see fig. 4.8).

- Install and adjust the tension of the attachment drive belt.

- Install the engine control unit (ECU).

- Install the air conditioning and power steering hydraulic hose clamps and secure with bolts.

- Install the engine mount bracket.

- Install the lower right engine mudguard.

- Connect the wire to the negative battery terminal.