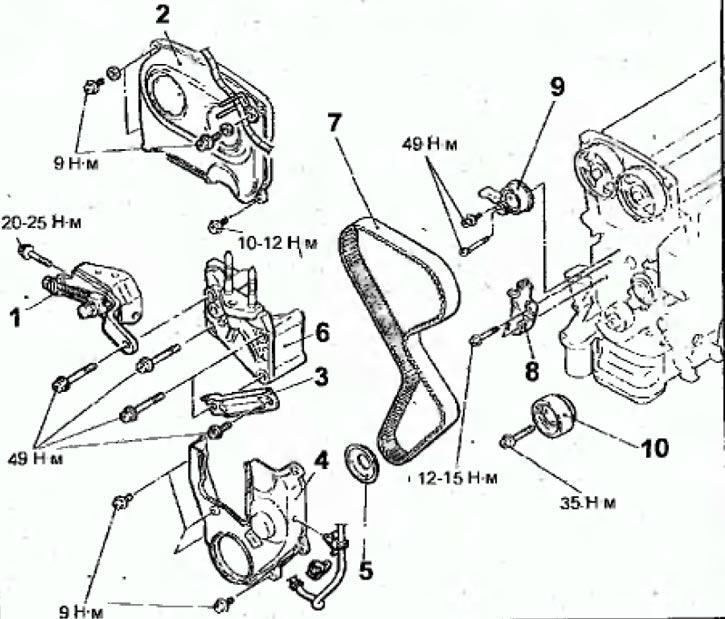

Pic. 2.41. Toothed timing belt: 1 - generator tension bar; 2 - upper front casing of the toothed belt; 3 - support bracket for the power steering pump; 4 - lower front casing of the toothed belt, 5 - flange; 6 - engine support bracket; 7 - toothed belt drive timing mechanism; 8 - automatic belt tension mechanism; 9-pulley and lever of the belt tension mechanism; 10 idle pulley

Removing

- Disconnect the wire from the negative battery terminal.

- Turn out bolts and remove a cover from the engine.

- Remove the lower engine mudguard.

- Remove the poly V-belt drive crankshaft pulley.

- Turn out bolts and remove a tension level of the generator.

- Turn out bolts and remove the top forward casing of a gear belt.

- Remove the bolts and remove the power steering pump support bracket.

- Turn out bolts and remove the bottom forward casing of a gear belt.

- Remove the flange.

- Loosen the bolts and remove the engine support bracket

- Turn out bolts and remove an arm of support of the engine.

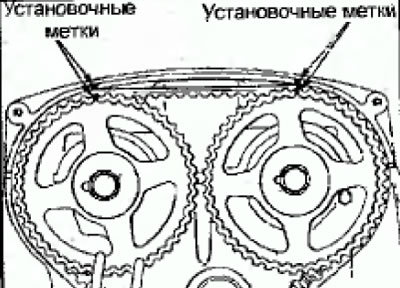

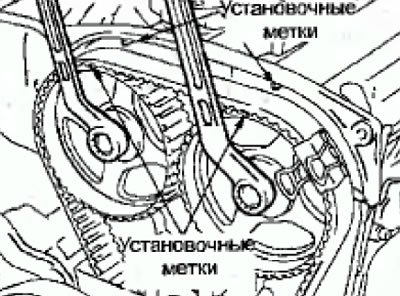

- Turn the crankshaft clockwise until the alignment marks on the camshaft pulleys align with the corresponding fixed marks (pic. 2.42).

Pic. 2.42. Alignment of the alignment marks on the camshaft pulleys with the corresponding fixed marks

Warning. Turn the crankshaft only clockwise.

- Loosen the adjusting bolt of the timing belt tensioner mechanism and remove the timing belt.

Warning. If the timing belt is reused, chalk on the reverse (not working) the surface of the belt an arrow indicating the direction of rotation of the belt (clockwise).

- Turn out bolts and remove the mechanism of an automatic tension of a gear belt.

- Turn out a bolt and remove a pulley of the mechanism of a tension of a gear belt.

- Turn out a bolt and remove the lever of the mechanism of a tension of a gear belt.

Examination

Toothed belt

After repairing the engine or adjusting the belt tension, check the condition of the belt. Replace the toothed belt if the following defects are present:

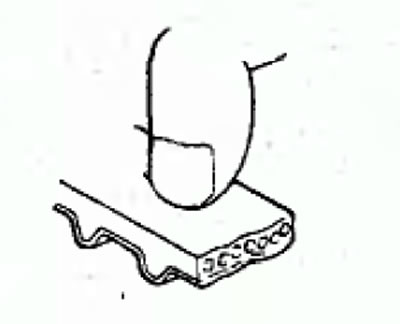

- hard back surface of the toothed belt or if the surface has a glossy appearance. The hardness of the surface is such that the nail does not leave marks on the belt (pic. 2.43);

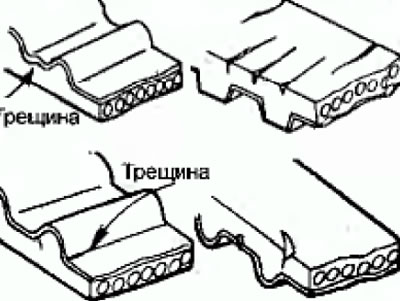

- surface cracks or delaminations of the toothed belt (pic. 2.44);

- cracks on the side surface of the toothed belt (pic. 2.45) The side edges of the belt should have a pronounced right angle. If the side surface of the belt is twisted, then the side surface of the belt is heavily worn;

- missing teeth, severely worn teeth, or wear on the side of the tooth, exposing fibers, cord, and rubber backing (pic. 2.46).

Fig.2.43. Checking the rigidity of the toothed belt surface

Pic. 2.44. Cracks on the surface or delamination of the toothed belt

Pic. 2.45. Cracks or severe wear on the side of the toothed belt

Fig.2.46. Heavily worn teeth or tooth side wear of the toothed belt

Timing Belt Automatic Tensioner

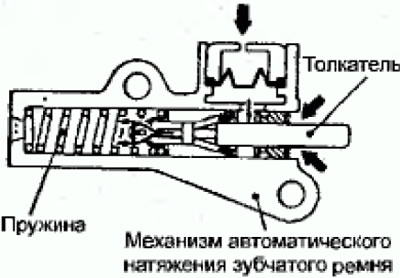

Check the timing belt automatic tensioner for possible leaks (pic. 2.47).

Pic. 2.47. Timing Belt Automatic Tensioner

Check the toothed belt tensioner tappet for cracks and wear.

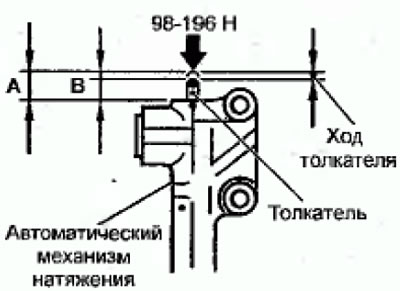

Check the serviceability of the automatic toothed belt tensioner, for which, press the end of the pusher with a force of 98-196 N by hand and check the distance that the pusher moves (pic. 2.48). If the stroke of the pusher of the tensioner does not correspond to the required value, replace the toothed belt tensioner.

Pic. 2.48. Place of measurement of the stroke of the pusher

Rated distance: about 1mm

A: the distance that the pusher protrudes without applying force;

B: the distance that the pusher protrudes with the application of force

A-B: pusher stroke = 1 mm

- If the amount of movement of the pusher does not correspond to the nominal value, replace the automatic tensioner of the toothed belt

Installation

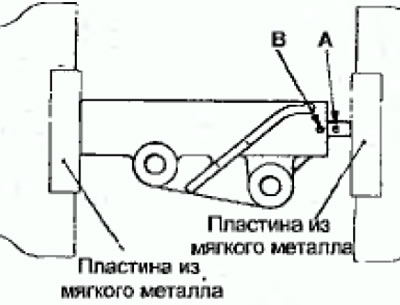

If the push rod of the automatic toothed belt tensioner is fully extended from the housing, push it back as follows.

Warnings. When pushing the plunger into the automatic vise tensioner, set the plunger perpendicular to the jaws of the vise.

If there is a plug at the base of the auto-tensioner, install a flat washer on the end of the auto-tensioner to protect it.

- Place two pieces of soft metal on the vise jaws. Then place the tensioner between the vise jaws.

Warning. Do not force the pusher out very quickly as it may be damaged.

- Slowly squeeze the jaws of the vise and press the pusher into the tensioner housing so that the holes in the pusher line up (A) and corps (B, fig. 2.49).

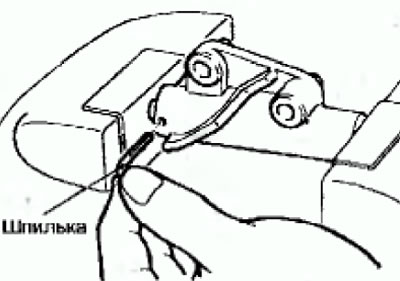

- Insert a stud or steel wire with a diameter of 1.4 mm into the aligned holes and remove

Pic. 2.49. The location of the holes in the pusher (A) and corps (IN) toothed belt tensioner

Pic. 2.50. Installing the pin in the combined holes of the pusher and the housing of the toothed belt tensioner

Note. If a new toothed belt tensioner is used, the stud is already inserted into it.

Warning. Do not remove the pin from the toothed belt tensioner

- Install the timing belt tensioner to the engine.

- Using special tools, turn the crankshaft into the pulley mounting bolt until the alignment marks on the crankshaft pulley align with the corresponding fixed mark (pic. 2.51).

- Align the timing marks on the camshaft pulleys with the corresponding fixed marks (see fig. 2.51).

- Loosen the center bolt securing the tensioner pulley.

- Turn the crankshaft pulley counterclockwise by half a tooth.

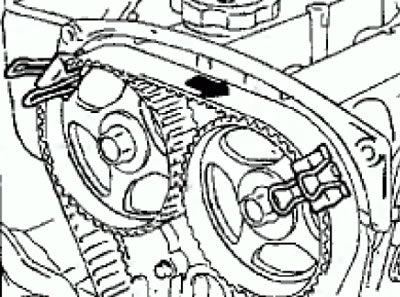

- Lay the timing belt on the exhaust camshaft pulley and secure it with a double clip (pic. 2.52).

- Lay the timing belt on the intake camshaft pulley, while using two ring wrenches, align the alignment marks, as shown in Figure 2.53.

- Secure the toothed belt to the intake camshaft pulley with a second double clip (pic. 2.54).

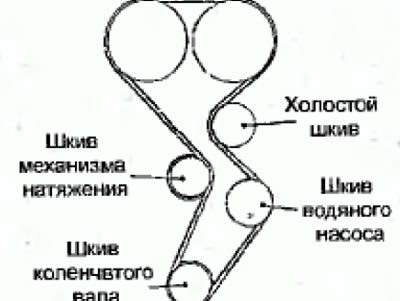

- Sequentially install the toothed belt onto the idler pulley, water pump pulley, crankshaft pulley and tensioner pulley (pic. 2.55).

- Remove clamps.

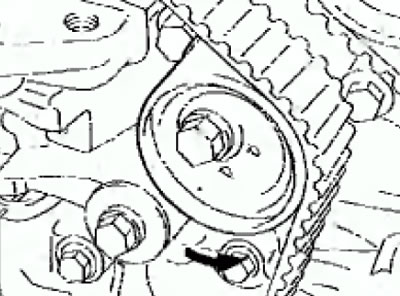

- Turn the pulley of the tension mechanism in the direction of the arrow shown in Figure 2.56, and tighten the bolt securing the pulley of the tension mechanism.

- Check the alignment of all alignment marks.

- Adjust the toothed belt tension.

Pic. 2.51. Alignment of alignment marks on the pulleys of the camshafts and the crankshaft

Pic. 2.52. Using a double clip to secure the toothed belt to the exhaust camshaft pulley

Pic. 2.53. Using two ring spanners to rotate the camshafts and align the timing marks on the camshaft pulleys

Pic. 2.54 Using a double clip to secure the toothed belt to the intake camshaft pulley

Pic. 2.55. Using two ring spanners to rotate the camshafts and align the timing marks on the camshaft pulleys

Pic. 2.56. The location of the toothed belt on the engine pulleys

Toothed belt tension adjustment

- Adjust the tension of the timing belt by turning the crankshaft ¼ turn counterclockwise, and then return it to its original position by turning it clockwise, and make sure that all the alignment marks are aligned.

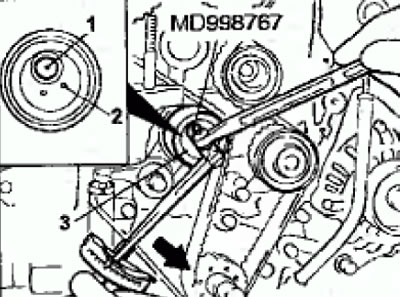

- Loosen the fixing bolt of the tensioner pulley and, with a special tool and a torque wrench, tighten the timing belt, then tighten the fixing bolt to a torque of 2.5-4.0 N·m (pic. 2.57).

Pic. 2.57. Adjusting the tension of the timing belt drive: 1 - fixing bolt; 2 - hole for the pin; 3 - tension pulley

Warning. When tightening the fixing bolt, make sure that the tensioner pulley is stationary at this time.

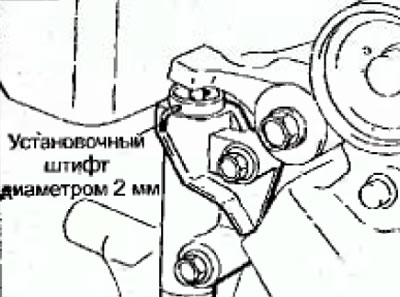

- Remove the 2mm dowel pin from the automatic tensioner (pic. 2.58). Make sure the pin is easy to remove.

- Rotate the engine 2 turns clockwise, wait at least 5 minutes, then check that the 2mm dowel pin can be easily removed or inserted into the auto-tensioner hole.

Fig. 2.58 Removing the locating pin with a diameter of 2 mm from the automatic tensioner

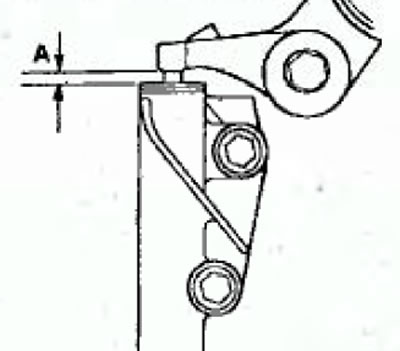

Note. Even if the locating pin is not installed in aligned holes, it will be sufficient if the protrusion of the stem from the tensioner is within 3.8-4.5 mm (pic. 2.59).

Pic. 2.59. Protrusion of the rod from the tensioner: A = 3.8 - 4.5 mm

Stem protrusion (A) from the tension mechanism: 3.8-4.5 mm

- If the protrusion does not correspond to the nominal value, repeat the belt tensioning operations.

- Make sure that the alignment marks on all pulleys are aligned with the fixed marks.

- Install the flange.

- Install the lower protective cover.

- Install the engine mount bracket.

- Install the crankshaft pulley.

- Connect the wire to the negative battery terminal.