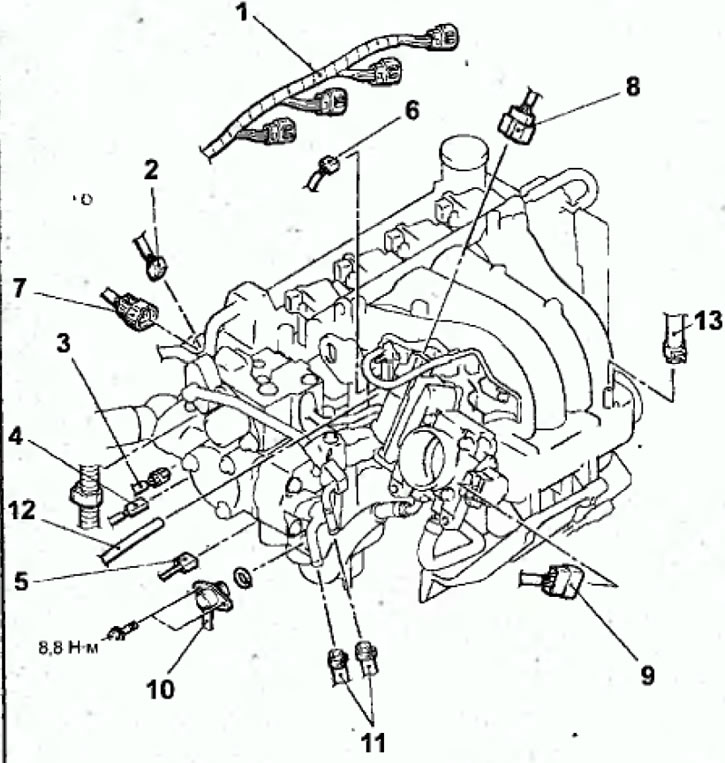

Pic. 2.60. Places for connecting connectors and hoses to the engine from 1999 of release: 1 - ignition coil connector; 2 - camshaft position sensor connector; 3 - coolant temperature sensor connector; 4 - connector for the sensor of the coolant temperature indicator; 5 - engine sensor connector; 6 - connector for the solenoid valve for cleaning the adsorber; 7 - fuel pressure sensor connector; 8 - throttle control servo connector; 9 - throttle position sensor connector; 10 - high pressure fuel hose connection; 11 - connections of fuel return hoses; 12 - vacuum hose connection; 13 - connection of the vacuum hose of the vacuum brake booster.

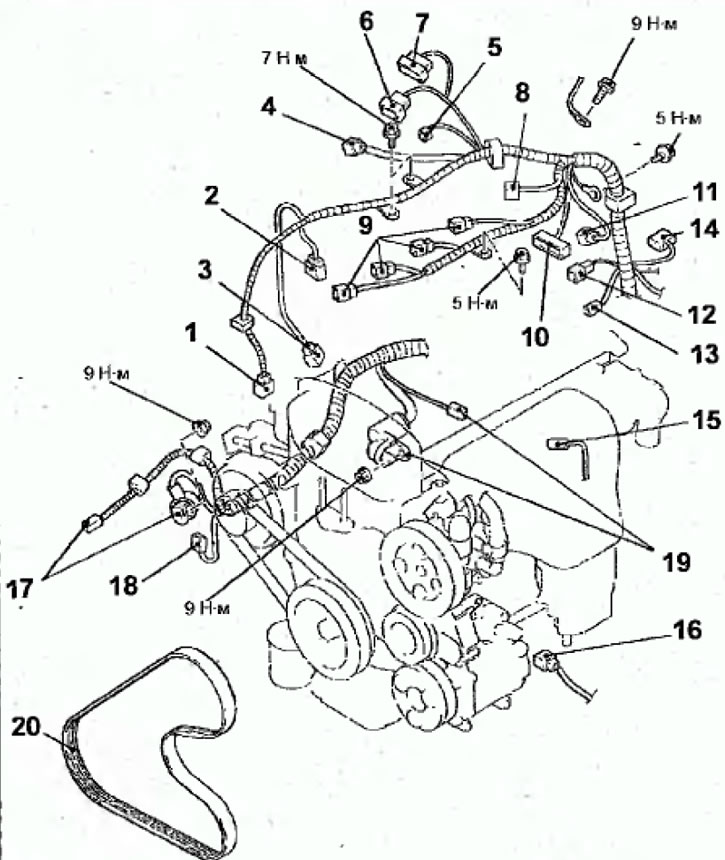

Pic. 2.61. Places for connecting connectors and hoses to the engine from 2000 of release: 1 - connector of the crankshaft angle sensor; 2 - fuel pressure sensor connector; 3 - connector of the front oxygen concentration sensor; 4 - connector of the wiring harness for control and EGR; 5 - connector of the solenoid valve for cleaning the adsorber; 6 - throttle position sensor connector; 7 - throttle control servo connector; 8 - injector wiring harness connector; 9 - ignition coil connector; 10 - connector for the sensor for detecting misfires; 11 - camshaft position sensor connector; 12 - coolant temperature sensor connector; 13- connector of the coolant temperature indicator sensor; 14 - knock sensor connector; 15 - pressure sensor connector in the hydraulic drive of the power steering; 16 - air conditioner compressor connector; 17 - generator connector; 18 - engine oil pressure sensor connector; 19 - starter connector; 20 - drive belt for power steering pump and air conditioning compressor

Removing

- Disconnect the wire from the negative battery terminal.

- To remove, perform the following steps in sequence.

- Relieve the fuel pressure in the fuel system. See chapter «Reducing the pressure in the fuel system», given in section «Direct fuel injection system (GDI)».

- Drain the coolant from the engine cooling system.

- Remove the hood.

- Remove the radiator.

- Remove the gearbox.

- Loosen the screws and remove the engine cover.

Warning. In figures 2.63 and 2.62 the sign (*) Elements are marked that, during installation, must be tightened first, and finally - after the car is lowered onto the wheels.

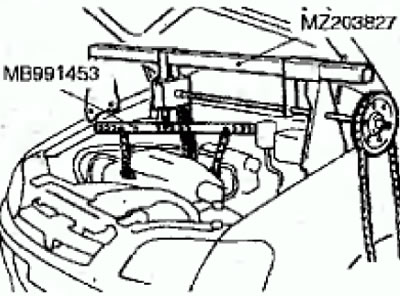

Pic. 2.62. Using a traverse to lift the engine from the engine compartment

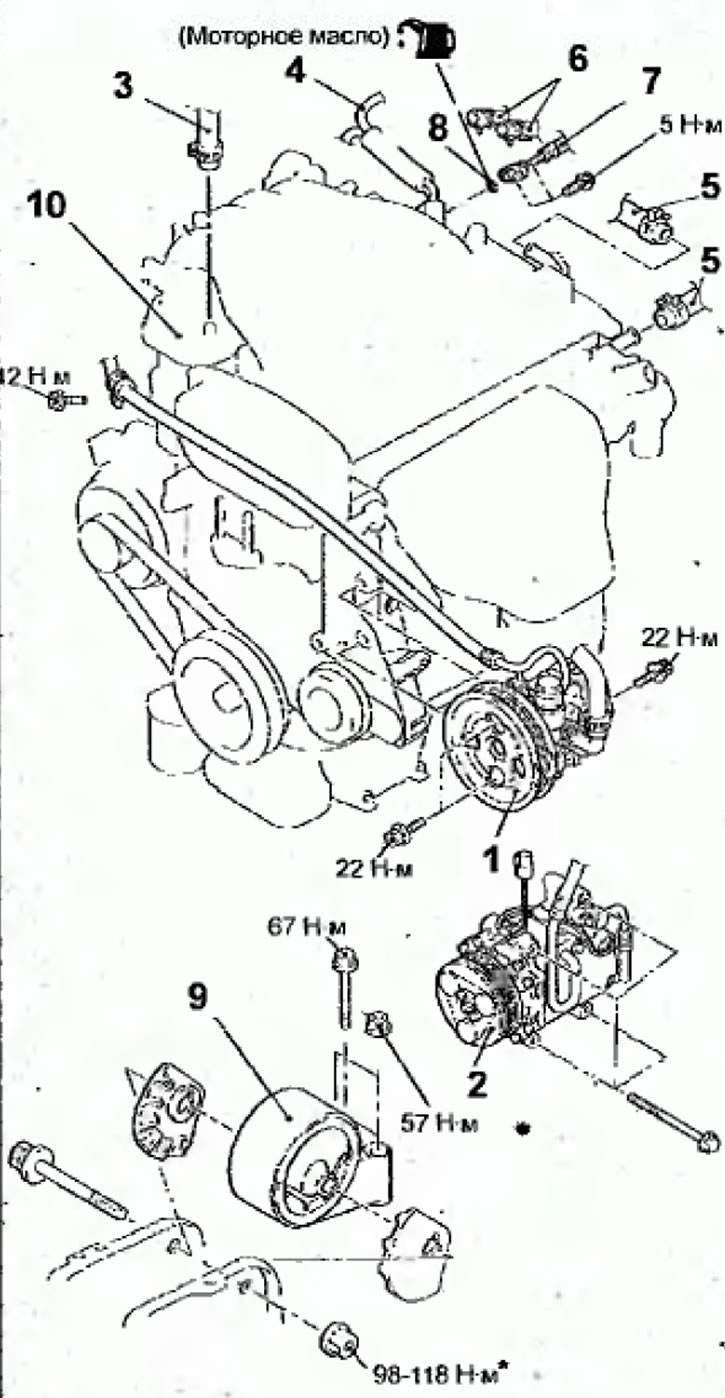

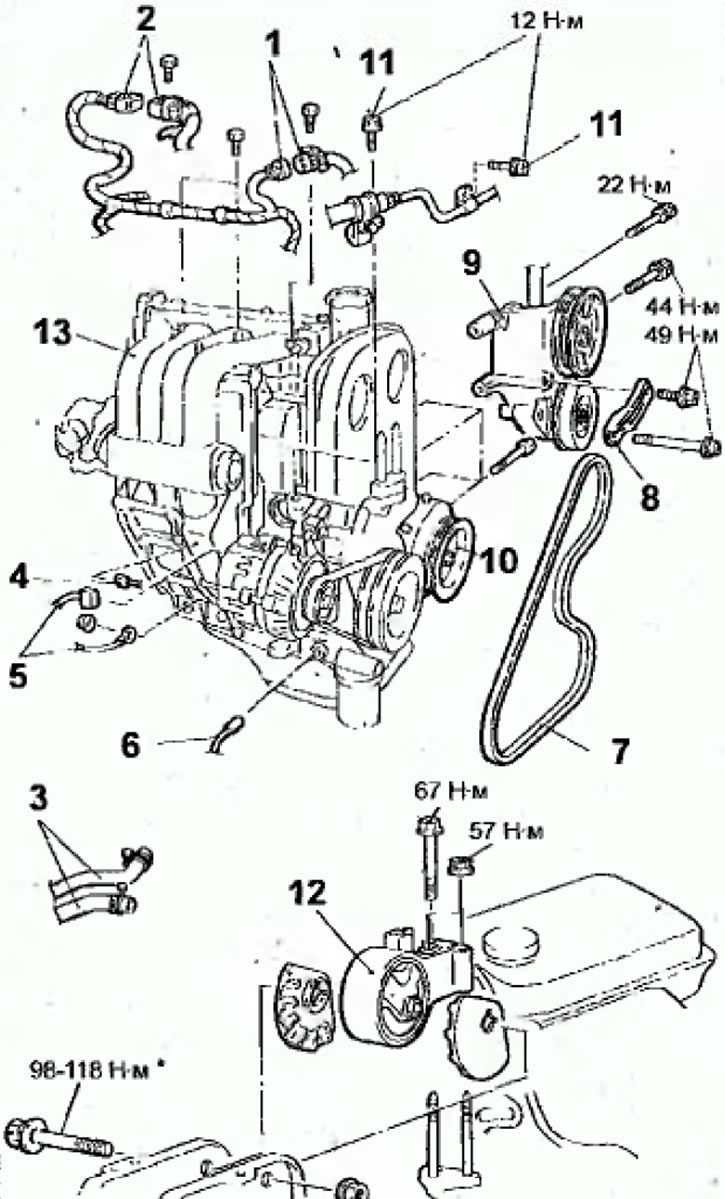

Pic. 2.63. Removable elements and elements of fastening of the engine since 2000 of release: 1 - power steering pump; 2 - air conditioner compressor; 3 - connection of the vacuum hose of the vacuum brake booster; 4 - vacuum hose connection; 5 - connection of heater hoses; 6 - connections of fuel return hoses; 7 - high pressure fuel hose connection; 8 - sealing ring; 9 - engine bracket; 10 - engine

Pic. 2.64. Removable elements and engine mounting elements from 1999 of release: 1 - connector of the crankshaft angle sensor; 2 - injector wiring harness connector; 3 - connection of heater hoses; 4 - oxygen concentration sensor connector; 5 - generator connector; 6 - engine oil pressure sensor connector; 7 - drive belt for power steering pump and air conditioning compressor; 8 - support bracket for the power steering pump; 9 - power steering pump and bracket; 10 - air conditioning compressor; 11 - a bolt of fastening of a hose of the hydraulic cylinder of the amplifier of a steering; 13 - engine bracket; 14 - engine

- Disconnect the connectors from the ignition coil, camshaft position sensor, coolant temperature sensor, coolant temperature gauge sensor, knock sensor, canister purge solenoid valve, fuel pressure sensor, throttle control servo, and throttle position sensor.

- On a 2000+ engine, disconnect the connectors from the starter power steering hydraulic pressure sensor, the fuel pressure sensor, and the misfire sensor.

- On the engine from 2000 release, disconnect the heater hoses.

- Turn out bolts, disconnect a fuel hose of a high pressure and remove an annular sealing lining.

- Loosen the clamps and remove the fuel return slags.

- Disconnect vacuum hoses.

- Disconnect the vacuum hose from the brake booster.

- Disconnect the connectors from the crank angle sensor, injector harness, oxygen sensor, alternator, and engine oil pressure sensor.

- Loosen the clamps and disconnect the heater hoses.

- Loosen the tension and remove the power steering pump and A/C compressor drive belt.

- Loosen the bolts and remove the power steering pump along with the attached hose and bracket.

Note. Use cord or soft wire to secure the removed power steering pump to the engine compartment so that it does not interfere with engine removal.

- Disconnect a socket, turn out bolts and remove the conditioner compressor together with the connected hoses from an arm.

Note. Secure the removed compressor in the engine compartment with a cord or soft wire so that it does not interfere with the removal of the engine.

- Turn out a bolt and disconnect from the engine a wire of connection with «weight».

- Install a rolling hydraulic jack under the engine.

- Remove the special tool used to remove the transmission from the engine.

- Fasten the motor to the yoke and hang it from a hoist or similar device (pic. 2.62).

- Insert a piece of wood between the jack foot and the engine oil pan and lift the engine slightly to relieve the weight of the engine support, then remove the engine support bracket.

- Make sure all wires are disconnected from the engine (electrical connectors), hoses, etc., and then slowly lift the engine up from the engine compartment.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- When installing the engine, make sure that the wires, hoses and wire connectors are not pinched.

- Place a hydraulic jack under the engine (by inserting a block of wood between the jack foot and the engine oil pan) and install the engine support bracket while adjusting the engine position with a jack.

- While supporting the engine with a jack, disconnect the hoist.

- When installing the high pressure fuel hose, lubricate the O-ring with a small amount of engine oil (pic. 2.65)

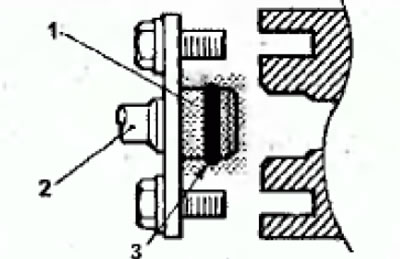

Pic. 2.65. High pressure fuel hose installation: 1 - a place for lubrication with engine oil, 2 - a fuel hose; 3 - ring gasket

Warning. Do not allow oil to enter the fuel line

- Slightly turning the fuel hose flange to the right or left, carefully insert it into the fuel line so as not to damage the O-ring. After installation, check that the hose turns smoothly in the fuel line.

- If the hose flange sticks when turning, the cause may be a damaged O-ring. Detach the flange (complete with hose) from the fuel line and check the gasket for damage, then reinsert it and check for smooth turning.

- Screw in the high pressure fuel hose mounting bolts and tighten them to 5 Nm.

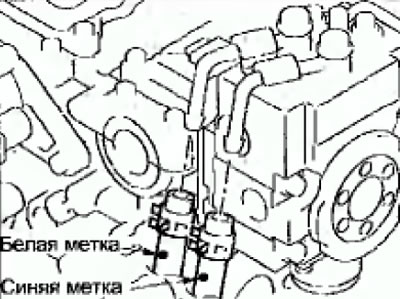

- On the engine since 2000, install the fuel return hoses so that the marks on the hoses are in the positions shown in Figure 2.66.

Pic. 2.66. Installation position of fuel return hoses