2. Turn off the ignition and connect the MUT-II device to the diagnostic socket.

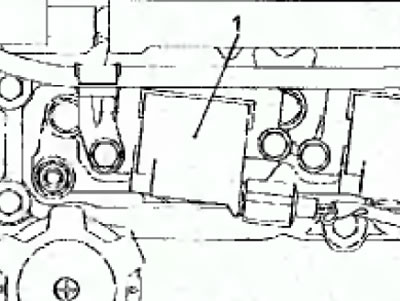

3. Connect the stroboscope to the high voltage wire (contact number 1) ignition coils #1 (pic. 2.6).

Pic. 2.6. Crankshaft Position Sensor Connector Location

Note. The #1 ignition coil high voltage wire is loop-shaped and longer than the other high voltage wires.

4. Start the engine and let it idle.

5. Using the MUT-II, check the idle speed, which must correspond to the nominal value.

Engine idle speed: 600±100 min-1*

Note

(1) *: The engine idling speed of a manual transmission vehicle changes according to the transmission oil temperature.

(2) After 4 minutes of running the engine at idle, the engine speed should be about 750 min-1 (pic. 27).

6. On the MUT-II select Actuator test

Note. At this time, the engine speed should be about 750 min-1

7. Check the setting of the main ignition timing, which must correspond to the nominal value.

Setting the ignition timing: 5°±3°to TDC

8. If the basic ignition timing is not correct, check the GO system.

9. On the MUT-II, press the button «Cancellation of forced activation of actuators» (Select a forced driving cancel mode) and cancel the mode «Actuator test».

Warning. If the test mode is not canceled, the forced activation mode of the actuators will continue for 27 minutes. Driving under these conditions can result in engine damage.

10. Check that the basic ignition timing is within acceptable limits.

Basic ignition timing: 16°to TDC

Notes

(1) The ignition timing will be set to about 6°BTDC 4 minutes after the basic ignition timing test is cancelled.

(2) The ignition timing setting fluctuates around±7°BTDC even under normal operating condition.

(3) With an increase in the frequency of rotation of the engine crankshaft, the ignition timing can vary within 5°from the nominal.

11. Remove the stroboscope.

12. Turn off the ignition and disconnect the MUT-II.