Examination

1. Check belt tension as follows:

Warning. Switch off the ignition before connecting or disconnecting the MUT-II.

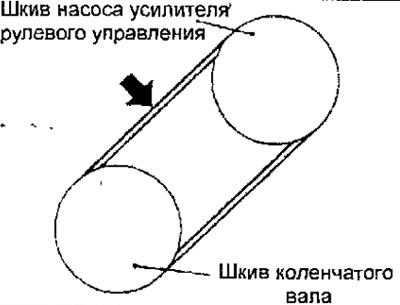

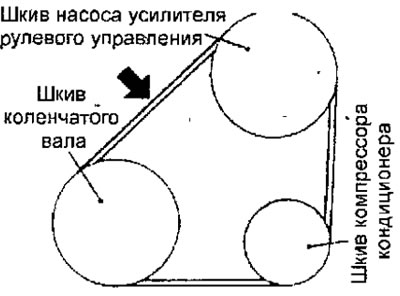

With your hand, gently press the belt between the pulleys in the place indicated by the arrow in figures 3.5 and 3.6. and check that the belt frequency is correct.

Pic. 3.5. Checking the tension of the power steering pump drive belt

Pic. 3.6. Checking the tension of the power steering pump and air conditioning compressor drive belt

Note. For detailed information on measuring the oscillation frequency using the MUT-II, see chapter «Checking and adjusting the tension of the alternator drive belt».

Without using the MUT-II

With a special tool for measuring belt tension, check that the tension is correct (pic. 3.5, 36).

By deflection of the belt

1. Apply a force of approximately 98 N in the center of the belt leg between the pulleys at the point indicated by the arrow in Figures 3.5 and 3.6 and check that the deflection value is correct.

Power steering pump and air conditioning compressor drive belt tension:

- when checking:

- oscillation frequency: 137-168Hz

- tension: 392-588 N

- deflection: 9.6-12.4mm

- when installing a used belt:

- oscillation frequency: 145-160Hz

- tension: 441-539 N

- deflection: 10.2-11.6mm

- when installing a new belt:

- oscillation frequency: 174-199 Hz

- tension: 637-833 N

- deflection: 7.2-9.0mm

2. If the measured values of belt tension and deflection differ from the nominal values, adjust as follows:

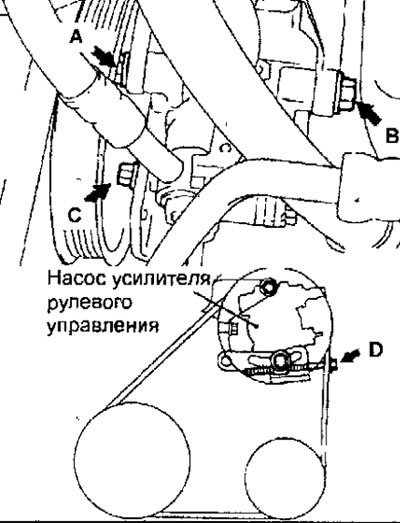

(1) Loosen bolts A, B and C (pic. 3.7) power steering pump mounts.

Pic. 3.7. Adjustment of a tension of a belt of a drive of the pump of the amplifier of a steering and the compressor of the conditioner

(2) By turning the adjusting bolt D, adjust the deflection of the belt.

(3) Tighten bolts A, B and C of the power steering pump.

Torque:

- bolts A and B: 44 Nm

- bolt C: 49 Nm

(4) Check belt deflection and tension and re-adjust if necessary.

Warning. The check is carried out after turning the crankshaft one revolution clockwise.