Removing

- Disconnect the wire from the negative battery terminal.

- Reduce the pressure in the fuel system.

- Drain the coolant from the cooling system.

- Remove the plug and drain the engine oil from the engine.

- Remove the thermostat cover.

- Turn out bolts and remove a clip of fastening of a cable of an accelerator (pic. 3.30).

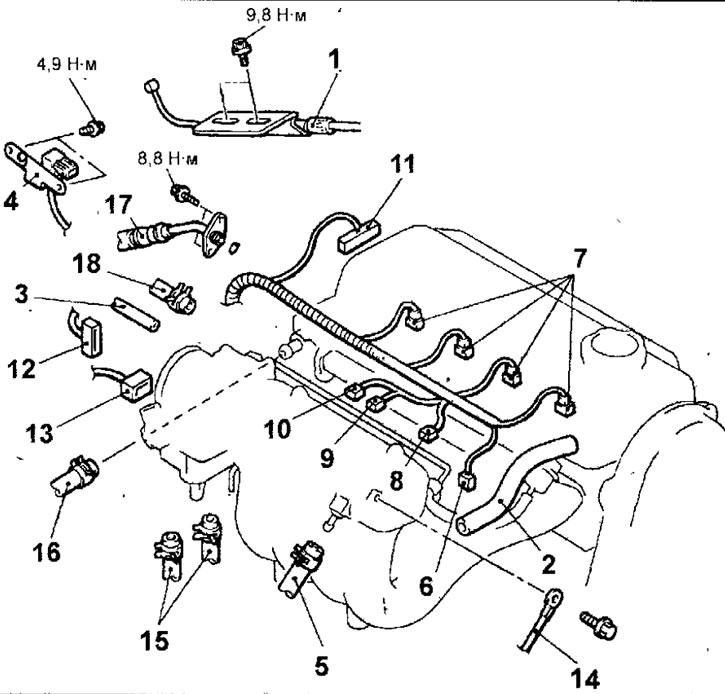

Pic. 3.30. Cylinder head: 1 - clamp fastening the accelerator cable; 2 - crankcase ventilation hose; 3 - vacuum hose; 4 - boost pressure sensor and bracket; 5 - vacuum hose of the vacuum brake booster; 6 - knock sensor connector; 7 - nozzle connector; 8 - connector for the temperature sensor of the air entering the engine; 9 - connector for the solenoid valve for cleaning the adsorber; 10 - connector for the exhaust gas recirculation solenoid valve; 11 - ignition distributor connector; 12 - throttle position sensor connector; 13 throttle control servo connector; 14- wire connecting the engine block with «weight»; 15 - hoses of the engine cooling system; 16 - heater hose; 17 - high pressure fuel hose; 18 - fuel return hose

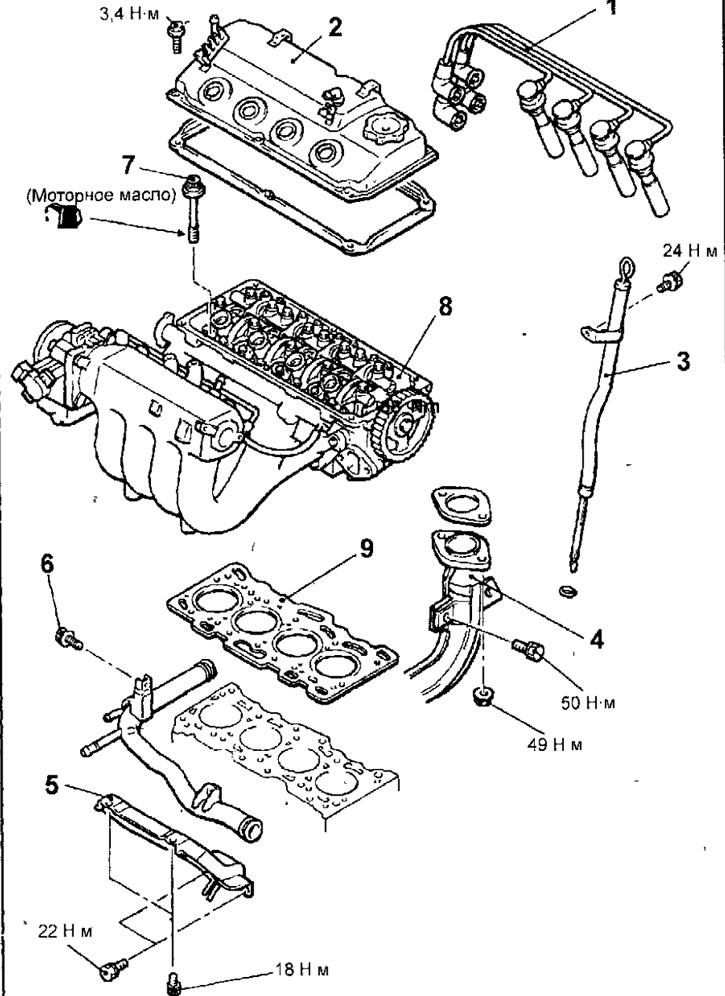

Pic. 3.31. Cylinder head: 1 - high-voltage wires; 2 - cylinder head cover; 3 - guide tube for the engine oil level indicator: 4 - intake exhaust pipe; 5 - intake manifold bracket; 6 - bolt, 13 Nm; 7 - cylinder head bolt, 49 Nm + loosen + 20 Nm + 90°+ 90°; 8 - cylinder head assembly; 9 - cylinder head gasket

- Loosen the clamp and disconnect the crankcase ventilation hose from the cylinder head cover pipe.

- Disconnect the vacuum hose.

- Remove the bolts and remove the boost pressure sensor and bracket,

- Loosen the clamp and disconnect the brake booster vacuum hose.

- Disconnect the connectors from the knock sensor, injectors, engine air temperature sensor, canister cleaning solenoid valve, EGR solenoid valve, ignition distributor, throttle position sensor, and throttle control servo.

- Turn out a bolt and disconnect a passage of connection of the block of cylinders of the engine with «weight».

- Loosen the clamps and disconnect the engine and heater cooling system hoses.

- Turn out bolts, disconnect a fuel hose of a high pressure and remove an annular sealing lining.

- Loosen the clamp and disconnect the fuel return hose.

- Remove high voltage wires.

- Turn out bolts and remove a cover of a head of cylinders.

- Remove the timing belt drive timing.

- Turn out a bolt and remove a directing tube of the index of level of engine oil together with a sealing ring.

- Loosen the nuts securing the exhaust manifold flange to the exhaust manifold.

- Turn out a bolt and disconnect a reception exhaust pipe from a final collector.

- Turn out bolts and remove an intake manifold bracket.

- Turn out a bolt and remove a tube of system of cooling of the engine.

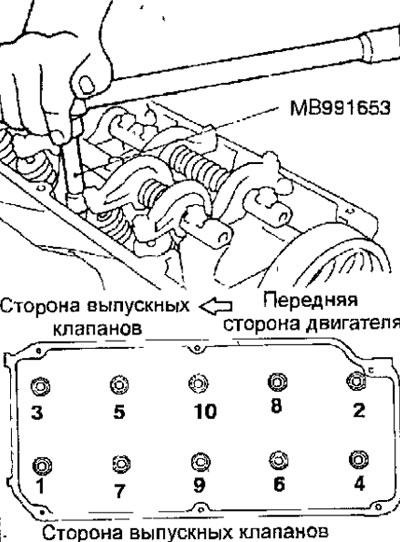

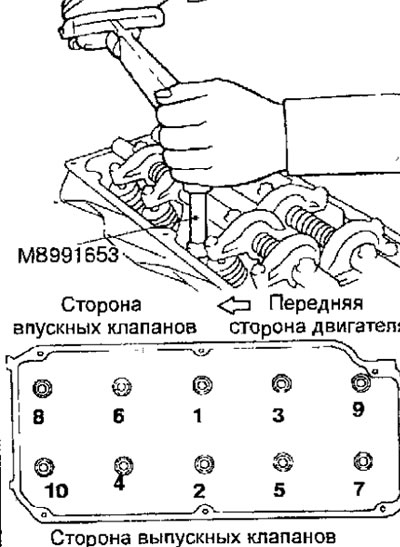

- Using a special tool for 2 or 3 passes in the sequence shown in Figure 3.32, loosen and unscrew the cylinder head bolts.

Pic. 3.32. The sequence of turning out the bolts of the cylinder head

- When removing the cylinder head bolts, be careful not to damage or deform the spark plug guide tubes as they are not replaceable.

- Being careful, remove a head of the block of cylinders.

- Remove the spark plug guide tube o-rings.

- Remove the cylinder head gasket.

- Cover the engine cylinders with a clean, lint-free cloth.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- Degrease the attached surfaces of the block and cylinder head.

- When installing, check the alignment of all holes on the gasket and cylinder head.

- Install the gasket and cylinder head to the cylinder block.

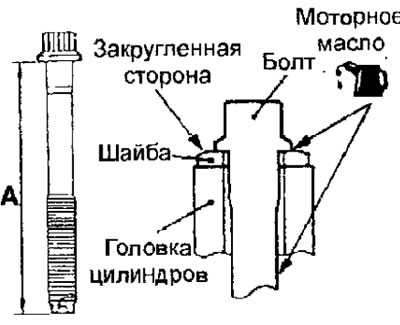

- Check the condition of the cylinder head bolts and especially their threads. Measure the length of each bolt (without puck) from the underside of the bolt head to the end of the bolt. If the bolt length (Ah, fig. 3.33) less than 103.2 mm, they can be reused. If any bolt is longer than specified, replace all bolts in the kit.

Pic. 3.33. Arrangement of a bolt and a washer of fastening of a head of cylinders: And =103,2 mm

- Install washers on the cylinder head under the head mounting bolts, rounded side up, as shown in Figure 3.33.

- Lubricate the top surface of the washer and bolt threads with engine oil before installing.

- Tighten the cylinder head bolts in several stages in the sequence shown in Figure 3.34.

Fig.3.34 The sequence of tightening the cylinder head bolts

Steps for tightening the cylinder head bolts:

- step 1: tighten to 49 Nm

- Step 2: Completely loosen all bolts in the reverse order of Figure 3.34

- step 3: tighten to 20 Nm

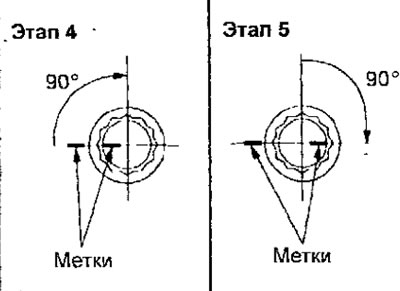

- Step 4: Tighten the bolts by 90°. Apply paint marks on the bolt heads and cylinder head (pic. 3.35)

- Step 5: Tighten the bolts an additional 90°The marks on the bolts and the cylinder head must be in line (pic. 3.35)

Pic. 3.35. Turning the cylinder head bolts

Warnings.

- (1) Always turn the bolt to a strict 90°angle. Otherwise, the cylinder head bolt may be loosened (the reliability of the gas connection will not be ensured).

- (2) If the bolt is turned more than 90°, loosen it completely and repeat all bolt tightening operations.

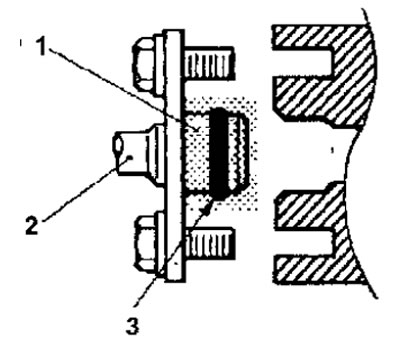

- When installing the high pressure fuel hose, lubricate the O-ring with a small amount of clean engine oil (pic. 3.36).

Pic. 3.36. High pressure fuel hose installation: 1 - place of lubrication with engine oil; 2 - fuel hose; 3 - ring gasket

Warning. Do not allow oil to enter the fuel line.

- Slightly turning the fuel hose flange to the right or left, carefully insert it into the fuel line so as not to damage the O-ring. After installation, check that the hose turns smoothly in the fuel line.

- If the hose flange sticks when turning, the cause may be a damaged O-ring. Detach the flange (complete with hose) from the fuel line and check the gasket for damage, then reinsert it and check for smooth turning.

- Screw in the high pressure fuel hose mounting bolts and tighten them to 8.8 Nm.

- Install the thermostat housing.

- Connect and adjust the accelerator cable.

- Install the timing belt drive of the gas distribution mechanism.

- Fill the engine with the required amount of recommended engine oil.

- Pour coolant into the cooling system.

- Connect the wire to the negative battery terminal.

- Start the engine and check for leaks.