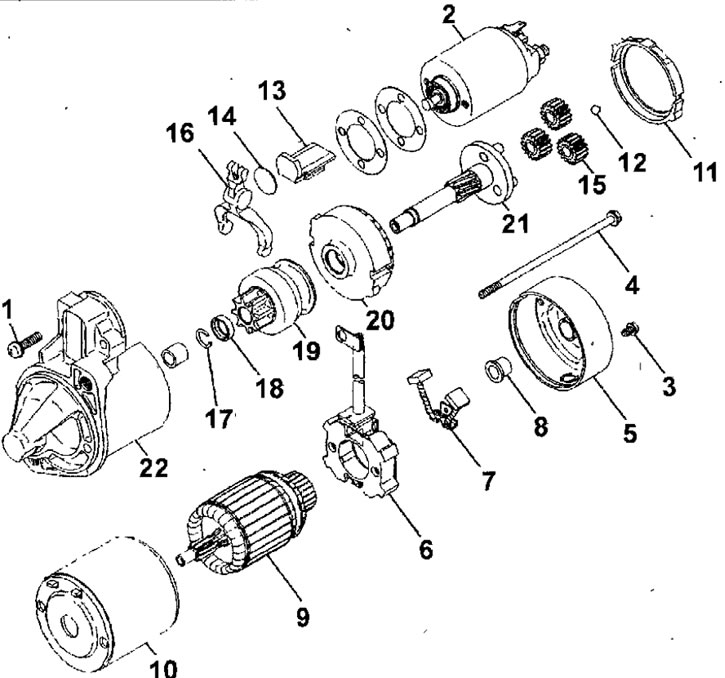

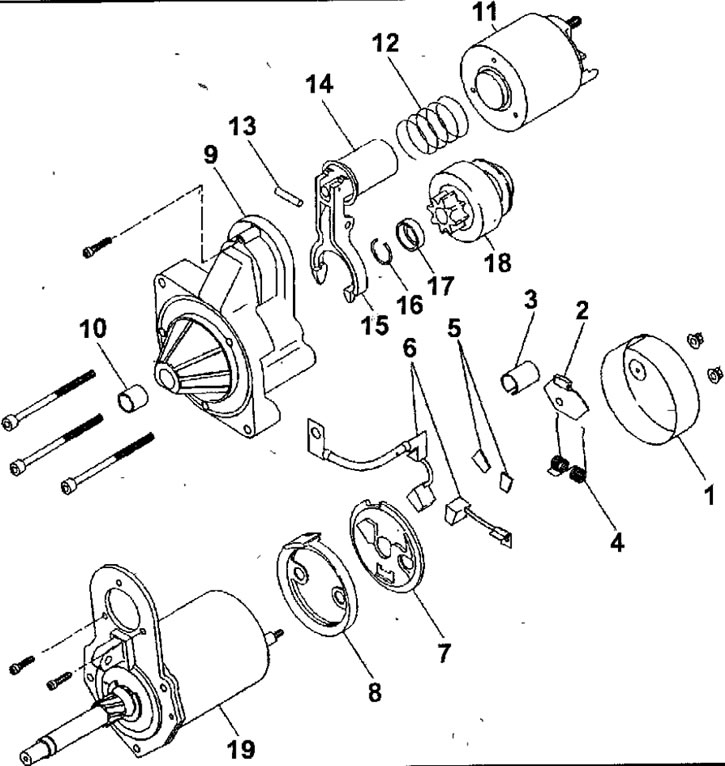

Pic. 19.40. 4G9 engine starter: 1—screw; 2 - traction relay; 3—screw; 4 pilot bolt; 5 - back cover; 6 - brush holder; 7 - brush; 8 - rear bearing; 9 anchor; 10-stator; 11 - gasket A; 12-ball; 13-laying B; 14-plate, 15 - satellites of the planetary gear; 1b - lever; 17 - retaining ring; 18 - thrust ring; 19 - freewheel; 20 - crown gear; 21 - sun gear; 22 - front cover

4G9 engine starter

Disassembly

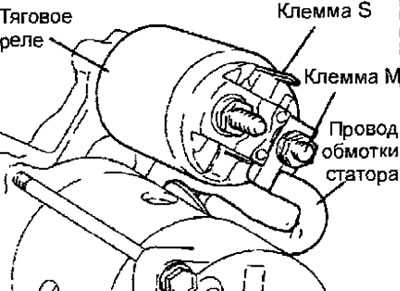

- Disconnect the wire of the excitation coil from the terminal M of the traction relay (pic. 19.41).

Pic. 19.41. Arrangement of contacts of the traction relay of a starter of the engine 4G9

- Turn out screws and remove the traction relay.

- Remove gasket and plate

- Loosen the screws and remove the back cover.

- Remove the rear bearing.

- Remove the brush holder assembly

- Remove the stator assembly with winding.

- Remove the starter anchor. When removing the anchor, do not lose the ball located at the end of the shaft.

- Remove the drive lever.

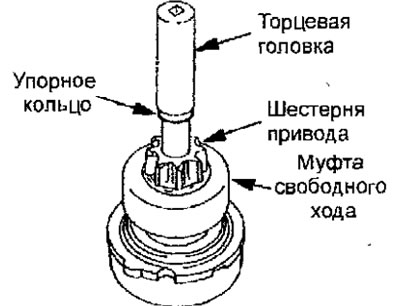

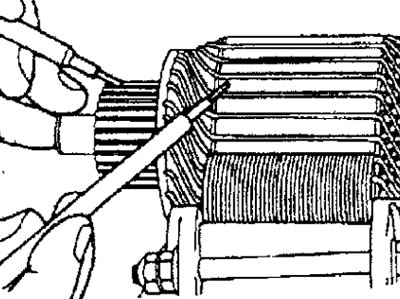

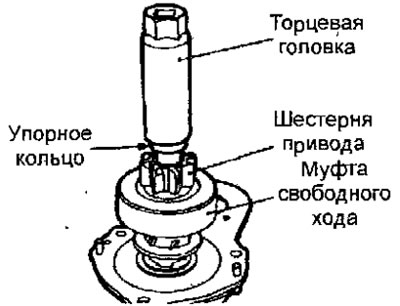

- Use a suitable socket to slide down the thrust ring (rice 19.42).

Pic. 19.42. Downward movement of the thrust ring

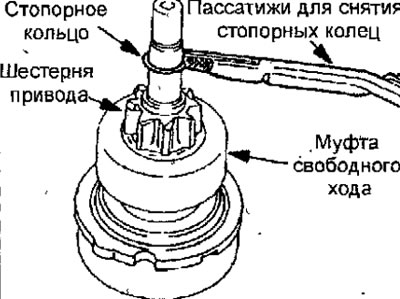

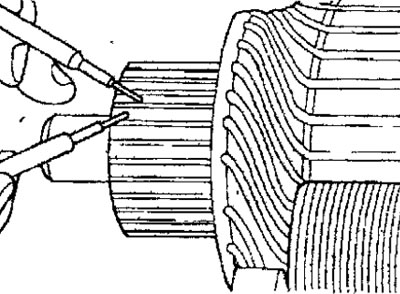

- Using special pliers, remove the retaining ring, then the thrust ring and freewheel (pic. 19.43).

Pic. 19.43. Removing the retaining ring

Manifold check

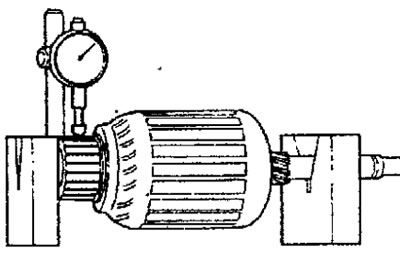

- Install the rotor on V-shaped supports and check the ovality of the collector with a pointer-type indicator (pic. 19.44).

Pic. 19.44. Manifold ovality check

Collector ovality:

- nominal: 0.05 mm

- maximum allowable: 0.1 mm

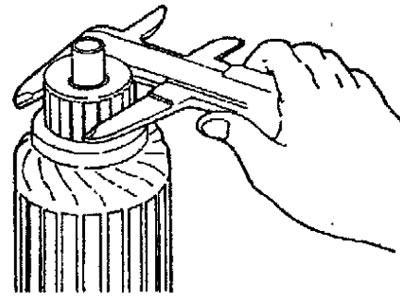

- Using a caliper, measure the outer diameter of the manifold (pic. 19.45).

Pic. 19.45. Manifold outer diameter measurement

Reduced Starter Manifold Outer Diameter:

- nominal: 32.0 mm

- minimum allowable: 31.0 mm

Manifold outer diameter:

- nominal: 29.4 mm

- minimum allowable: 28.4 mm

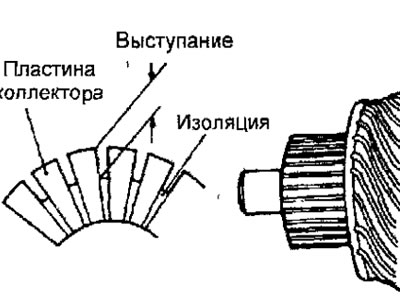

- Measure the protrusion of the collector plates from the insulation (pic. 19.46).

Pic. 19.46. Measurement point for the protrusion of the collector plates from the insulation

Protrusion of collector plates from insulation:

- nominal: 0.5 mm

- minimum allowable: 0.2 mm

Checking the freewheel

- Check the condition of the freewheel gear teeth and replace if damaged. Also check the condition of the flywheel gear teeth.

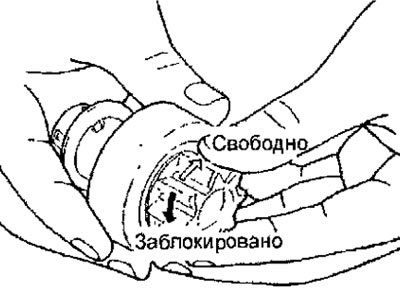

- Check gear. The gear should turn freely clockwise and lock when turned counterclockwise (pic. 19.47).

Pic. 19.47. Checking the freewheel

Brush and spring replacement

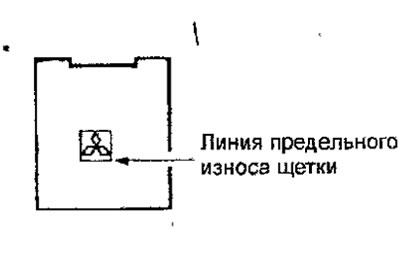

- Check the brushes for rough surfaces in contact with the commutator and Check the length of the brushes. Replace brushes worn below the limit line (pic. 19.48).

Pic. 19.48. Location of the starter brush wear limit line

- If the surface in contact with the commutator has been mechanically corrected, insert fine-grained sandpaper between the brushes and the commutator, with the abrasive layer of the paper on the side of the brushes, and by rotating the commutator, lap the brushes so that their contour coincides with the contour of the commutator.

Checking the rotor winding

- In a special device, check the rotor winding (pic. 19.49). If there are short circuits in the Rotor winding, replace the rotor. If the steel strip attached to the rotor vibrates, then there are short circuits in the rotor windings.

Pic. 19.49. Checking the rotor winding for short-circuited turns

- Ohmmeter Check continuity between collector and rotor (pic. 19.50). If there is continuity, replace the rotor.

Pic. 19.50. Conductivity test between collector and rotor

- Using an ohmmeter, check the conductivity between the collector plates (pic. 19.51). If there is no continuity, replace the rotor.

Pic. 19.51. Conductivity test between collector plates

Assembly

- The starter assembly is carried out in the reverse order of disassembly, taking into account the following.

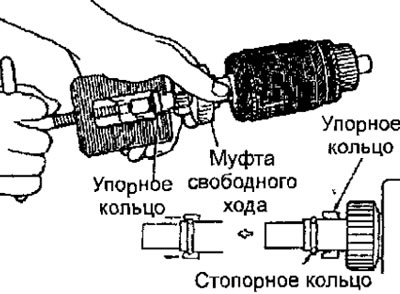

- Using the special tool, install the thrust ring and freewheel retaining ring on the front side of the rotor shaft, then move the thrust ring against the retaining ring (pic. 19.52).

Pic. 19.52. Installation of thrust and retaining rings

4G1 engine starter

Pic. 19.53. 4G1 engine starter: 1 - back cover; 2- rubber gasket; 3 - protective cover; 4 - brush spring; 5 - contact plates; 6 - brush; 7 - brush holder; 8 - sealing insert; 9 - front cover; 10 - bearing sleeve; 11 - traction relay; 12-spring; 13-axis drive lever; 14 core; 15 - drive lever; 16 - retaining ring; 17 - restrictive ring; 18 - freewheel; 19 - starter motor

Disassembly

- Loosen the nuts and remove the back cover.

- Remove the rubber pad.

- Remove the protective cover.

- Remove the brush spring.

- Remove contact plates.

- Remove the brushes.

- Remove the brush holder and sealing insert.

- Turn out bolts and remove a forward cover.

- Remove the bearing bush.

- Turn out screws and remove the traction relay.

- Remove the spring.

- Knock out the axis of the drive lever.

- Remove the core.

- Remove the drive lever.

- Use a suitable socket to slide down the thrust ring (pic. 19.54).

Pic. 19.54. Downward movement of the thrust ring

- Using special pliers, remove the retaining ring, then the thrust ring and freewheel (pic. 19.55).

Pic. 19.55. Removing the retaining ring

Checking the freewheel

- Check the condition of the freewheel gear teeth and replace if damaged. Also check the condition of the flywheel gear teeth.

- Check gear. The gear should turn freely clockwise and lock when turned counterclockwise (see fig. 19.47).

Checking commutator brushes

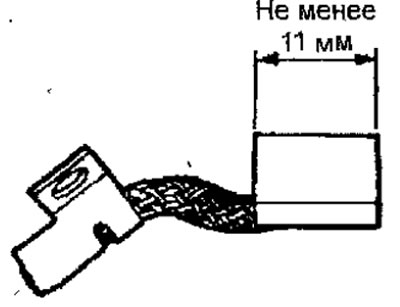

- Measure the length of the brush, which should be at least 11 mm (pic. 19.56).

Pic. 19.56. Place for measuring the length of the commutator brush

Assembly

- The starter assembly is carried out in the reverse order of disassembly, taking into account the following.

- Using the special tool, install the thrust ring and freewheel retaining ring on the front side of the rotor shaft, then move the thrust ring against the retaining ring (see fig. 19.52).

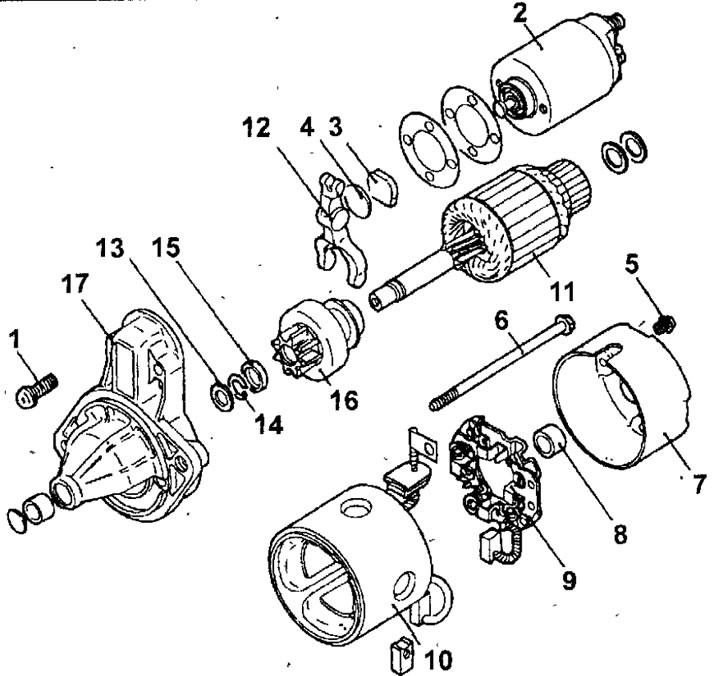

Engine starter 4G18

Pic. 19.57. 4G18 Direct Drive Motor Starter: 1 - screw; 2 - traction relay; 3 - gasket; 4 - plate; 5 - screw; 6 - coupling bolt; 7 - back cover; 8 - rear bearing: 9 - brush holder assembly; 10 - stator; 11 - starter anchor; 12 - drive lever; 13 - washer; 14 - retaining ring; 15 - thrust ring; 16 - freewheel; 17 - front cover

Disassembly

- Turn out screws and remove the traction relay.

- Remove the gasket and plate.

- Loosen the screws and remove the back cover.

- Turn out coupling bolts.

- Lower the rear bearing.

- Remove the brush holder assembly.

- Remove the stator.

- Remove the starter anchor.

- Remove the drive lever.

- Remove the puck.

- Use a suitable socket to slide down the thrust ring (see fig. 19.42).

- Using special pliers, remove the retaining ring, then the thrust ring and freewheel (see fig. 19.43).

Assembly

- The starter assembly is carried out in the reverse order of disassembly, taking into account the following.

- Using the special tool, install the thrust ring and the freewheel retaining ring on the front side of the rotor shaft, then move the thrust ring to the retaining ring (see fig. 19.52).