Checking and adjusting the axial clearance of the gear

- Disconnect the wire of the excitation coil from the terminal M of the traction relay.

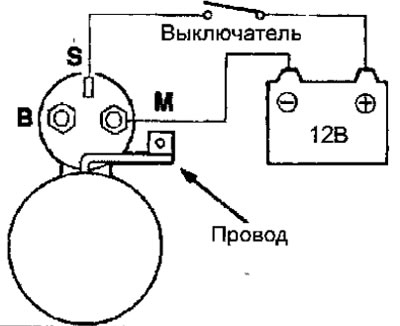

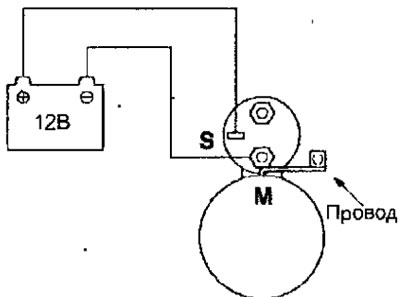

- Connect the battery terminals with the S and M terminals with additional wires (pic. 19.29).

Pic. 19.29. Starter connection diagram for checking and adjusting the axial clearance of the gear

- Turn the key in the ignition switch to the ON position, the drive gear will extend to the stop. This test must be completed within 10 seconds, otherwise the traction relay coil may burn out.

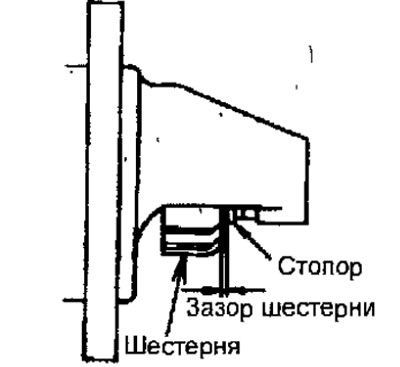

- Use a feeler gauge to check the clearance between the gear and the stopper (pic. 19.30).

Pic. 19.30. Starter gear clearance check

Gear clearance: 0.5-0.2mm

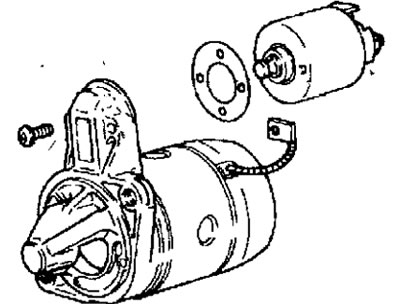

- If the gap differs from the required one, adjust it by adding or removing spacers between the traction relay and the front cover (pic. 19.31).

Pic. 19.31. Installation location of the gasket when adjusting the gap of the starter gear

Checking the retracting traction winding of the relay

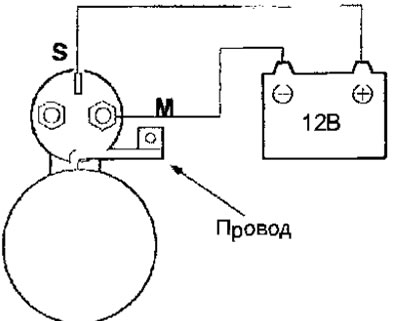

- Disconnect the wire of the excitation coil from the terminal M of the traction relay.

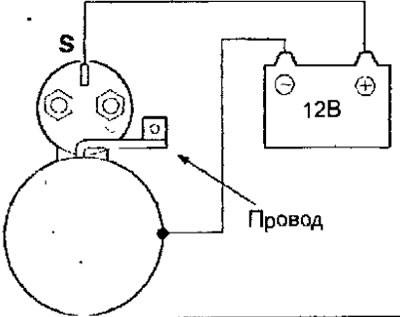

- Connect the battery terminals with the S and M terminals with additional wires (pic. 19.32, 19.33). This test must be completed within 10 seconds, otherwise the traction relay coil may burn out.

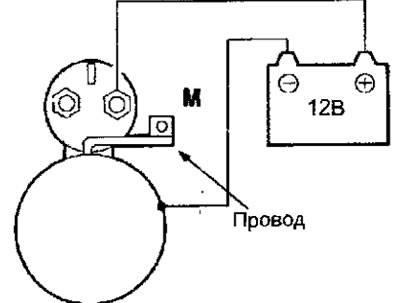

Pic. 19.32. Starter connection diagram when checking the 4G9 engine starter traction relay

Pic. 19.33. Starter connection diagram when checking the 4G1 engine starter traction relay

- If the drive gear extends, then the pull-in winding is OK. If the gear does not extend, replace the traction relay.

Checking the holding winding of the traction relay

- Disconnect the wire of the excitation coil from the terminal M of the traction relay.

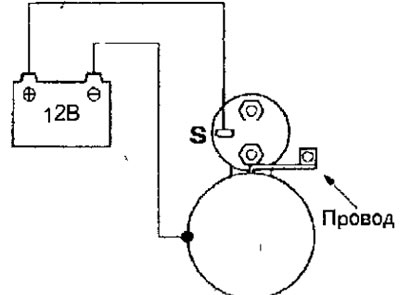

- Connect the battery terminals with the S terminal and the traction relay housing with additional wires (pic. 19.34). This test must be completed within 10 seconds, otherwise the traction relay coil may burn out.

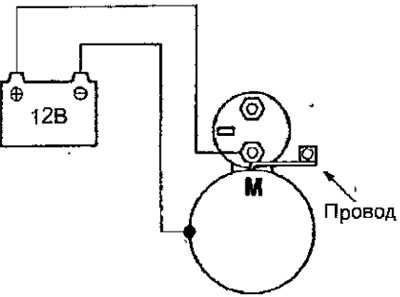

Pic. 19.34. Starter connection diagram when checking the holding winding of the traction relay of the 4G9 engine

Pic. 19.35. Starter connection diagram when checking the holding winding of the traction relay of the 4G1 engine

- Manually extend the drive gear until it stops.

- If the drive gear remains in the extended position, then the holding coil is good. If the gear retracts, then there is a break in the holding winding. In this case, replace the traction relay.

Performance test at idle

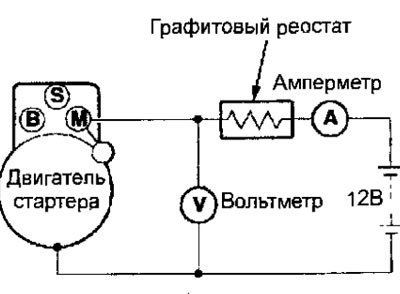

- To test at idle, secure the starter motor in a soft-jawed vise and connect wires from a fully charged battery to its leads as follows: (pic. 19.36, 19.37).

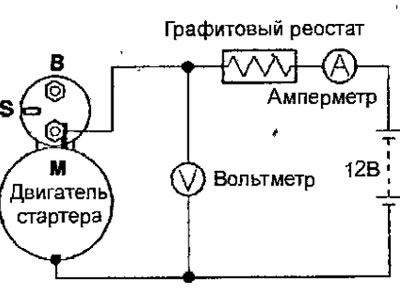

Pic. 19.36. Wiring diagram for performance tests of the starter motor 4G9 and 4G18

Pic. 19.37. Wiring diagram for performance testing of a 4G1 engine starter

- Set the graphite rheostat motor to a position where the voltmeter reads 11.0 volts while checking the current drawn by the starter and making sure the starter shaft turns easily and smoothly.

Current:

- 4G9 engine starter: no more than 50 A

- 4G1 engine starter: no more than 40 A

- 4G18 engine starter: no more than 60 A

- Disconnect the excitation coil wire from the M terminal of the traction relay.

- Connect the battery terminals with the M terminal and the traction relay housing with additional wires (pic. 19.38, 19.39). This test must be completed within 10 seconds, otherwise the traction relay coil may burn out.

Pic. 19.38. Wiring diagram when checking the return of the armature of the traction relay of the engine starter 4G9

Pic. 19.39. Connection diagram when checking the return of the armature of the traction relay of the engine starter 4G1

The starter gear should move forward. After disconnecting the wires, the starter gear should quickly return to its original position. Otherwise replace the traction relay.