Disassembly

1. Turn out bolts of fastening of directing fingers and remove a support from a support bracket (pic. 15.58). Remove the brake pads.

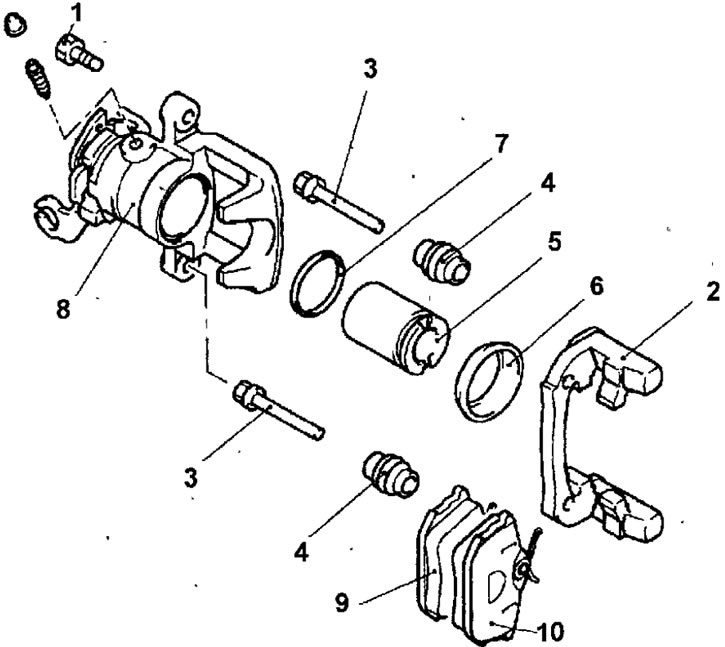

Pic. 15.58. Rear disc brake caliper: 1 - bolt; 2 - caliper bracket; 3 - guide pin: 4 - protective cover; 5 - piston; 6 - protective cover of the piston; 7 - piston sealing ring; 8 - support; 9 - brake shoe with wear indicator; 10-brake shoe

2. Remove protective covers and guide pins.

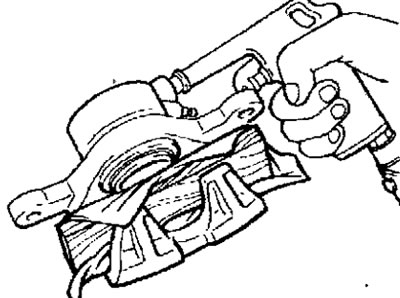

3. Remove the piston (pic. 15.59). To do this, place a block of wood between the piston and the outside of the caliper body. To remove the protective cover and piston, apply compressed air to the hole for the brake hose.

Pic. 15.59. Removing the piston from the caliper

Warnings

- If air is suddenly introduced into the brake cylinder body, the piston will fly out, damaging the caliper body. Blow compressed air gradually. When pushing the piston out with compressed air, do not place your fingers in front of the piston.

- Be careful, as brake fluid is blown out of the channel with compressed air along with the piston.

4. Remove the piston protector.

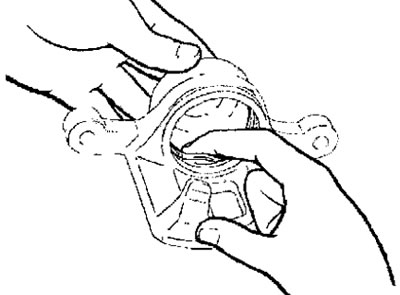

5. Use your finger to remove the piston o-ring (pic. 15.60).

Pic. 15.60. Removing the piston seal

Warning. Do not use a screwdriver or similar metal tools to remove the piston O-ring from the caliper cylinder as they may damage the cylinder walls.

6. Flush piston and cylinder surfaces with trichlorethylene, alcohol, or recommended DOT3 or DOT4 brake fluid.

Examination

1. Check the caliper cylinder for wear, damage or rust.

2. Check the piston surface for wear, damage or rust.

3. Check the caliper body and bushings for wear.

4. Check for damage or oiling of the brake pad linings, as well as for damage to the metal bases of the pads.

5. Check the thickness of the friction linings of the brake pads and, if necessary, replace the brake pads. Be sure to replace all pads on the same vehicle axle, even if only one pad is worn.

If the brake pads are to be reinstalled, they must be marked before removal.

Assembly

1. Assembly is carried out in the reverse order of removal, taking into account the following.

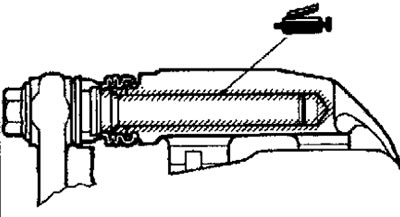

2. Before installing the guide pins, apply grease from the repair kit to the working surface of the pin and into the hole in the caliper bracket that the pin enters (pic. 15.61).

Pic. 15.61. Places for applying grease from the repair kit to the guide pins when assembling the caliper