Warning. When servicing disc brakes, special attention must be paid to meeting the technical requirements for disc brakes that ensure the normal operation of disc brakes.

Before restoring operations for machining or grinding the brake disc, the following parameters listed in the table must be checked.

Table for checking the parameters of the brake disc before its restoration

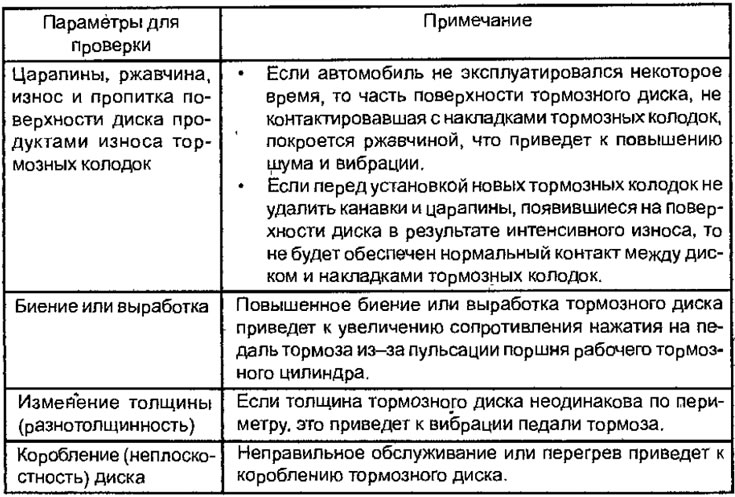

Checking the thickness of the brake disc

1. Using a micrometer, measure the thickness of the brake disc at eight points Approximately every 45°at a distance of 10 mm from the outer edge of the disc (pic. 15.22).

Pic. 15.22. Using a micrometer to measure the thickness of the brake disc

The disc thickness difference between any measured points shall not exceed 0.015 mm.

Brake Disc Thickness:

- nominal: 24.0 mm;

- minimum allowable: 22.4 mm.

2. The brake disc must be replaced if its thickness has become less than the minimum allowable. If the disc thickness difference exceeds the allowable value, replace the disc or turn it on a special lathe.

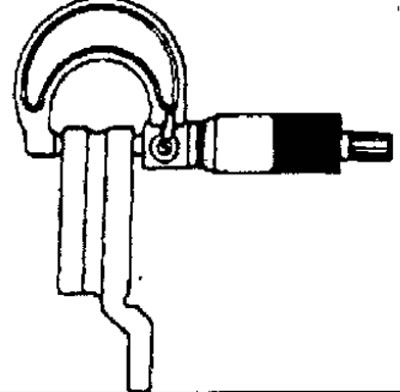

Checking brake disc runout

1. Remove the two caliper mounting bolts, lift the caliper and wire it to the front suspension strut (pic. 15.23).

Pic. 15.23. Location of the front brake caliper mounting bolts

2. Slowly turning the brake disc, visually check its condition; from two sides. Wear of the brake disc; from the pads must be within acceptable limits. If there are cracks on the disc, the disc must be replaced.

Before processing the brake disc, check its condition.

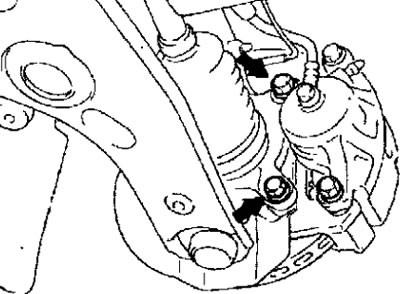

3. Use a dial indicator to check the runout of the brake disc. Fix the indicator in any convenient place and, turning the brake disc, determine its runout at a distance of 5 mm from the outer edge (pic. 15.24). Before checking brake disc runout, make sure the hub bearing is in good condition.

Pic. 15.24. Checking brake disc runout

Maximum allowable brake disc runout: 0.06 mm

Note. Tighten the wheel nuts to attach the brake disc to the hub.

Brake disc runout correction

1. If the runout of the brake disc meets or exceeds the limit value, it is necessary to change the relative position of the disc and the hub, and then measure the runout again.

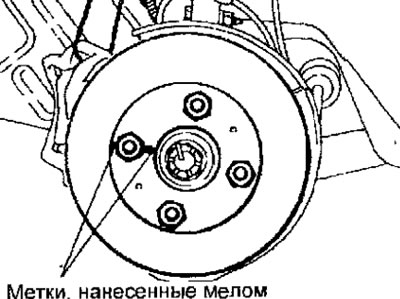

(1) Before removing the brake disc at the point of maximum runout with chalk i, mark both sides of the wheel stud (pic. 15.25).

Pic. 15.25. Marking location at the point of maximum runout of the brake disc

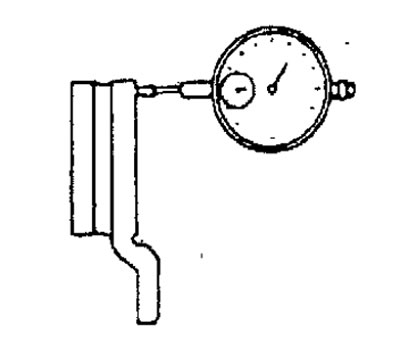

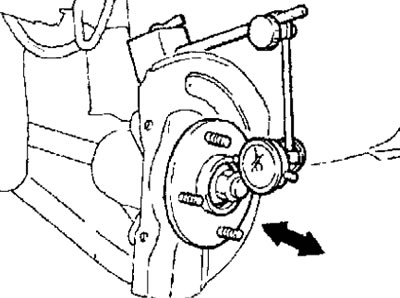

(2) Remove the brake disc and install the arrow type indicator as shown in Figure 15.26. Moving the hub in the axial direction, measure the axial play in the hub bearing. If the axial play is equal to or more than the limit value, then remove the hub and check the steering knuckle and hub.

Pic. 15.26. Installation of an arrow-type indicator to measure the axial play in the hub bearing

Maximum permissible axial play: 0.05 mm

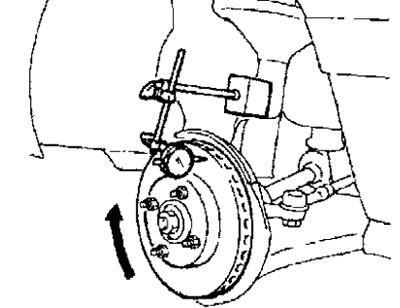

(3) If the axial play in the hub bearing does not exceed the limit, rotate the brake disc 180°with respect to the chalk line, install it on the hub and again measure the brake disc runout (pic. 15.27).

Pic. 15.27. Checking brake disc runout

2. If the performed operations have not eliminated the increased runout of the disc, replace the brake disc or process it on a special lathe.

Note. If the brake disc needs to be replaced, the second brake disc must also be replaced to ensure uniform braking. When replacing the brake discs, the brake pads must also be replaced.