Removing

- Disconnect the wire from the negative battery terminal.

- Discharge the refrigerant from the air conditioning system.

- Remove the lower mudguard of the engine compartment.

- On a vehicle with a 4G9 engine, remove the power steering pump.

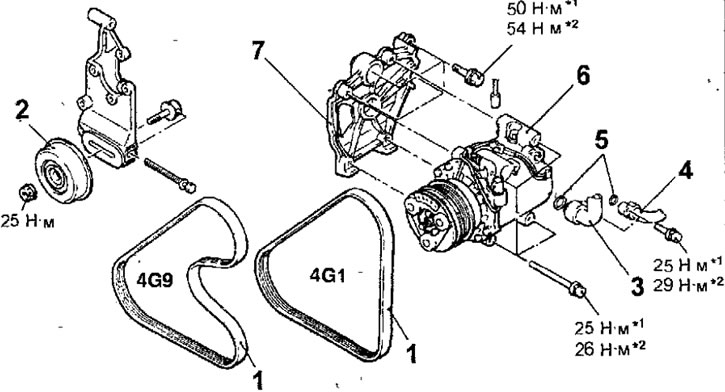

Note. Figure 18.26*1 bolts and nuts with a flange are marked, and*2- bolts and nuts with washers.

Pic. 18.26. Air conditioning compressor: 1 - air conditioning compressor drive belt; 2 - belt tension pulley (4G9 engine); 3 - suction hose; 4 - discharge hose; 5 - sealing ring; 6 - air conditioner compressor; 7 - air conditioner compressor bracket

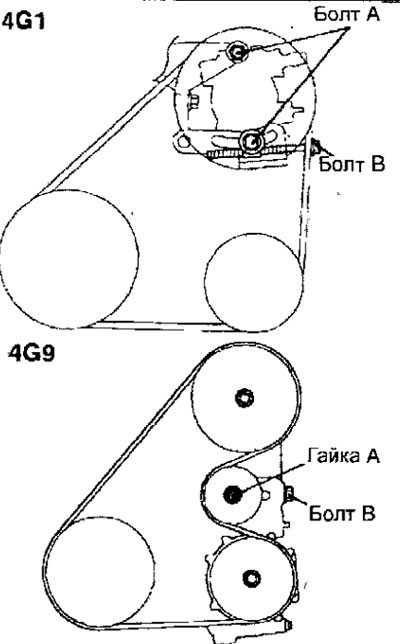

- Loosen the tension of the air conditioning compressor drive belt, for which loosen bolt A on a car with a 4G1 engine or nut A on a car with a 4G9 engine (pic. 18.27).

Pic. 18.27. The location of the bolts and nuts for adjusting the tension of the air conditioning compressor drive belt

- Loosen adjusting bolt B.

- Remove the A/C compressor drive belt.

- On a vehicle with a 4G9 engine, remove the A/C compressor drive belt tensioner pulley.

- Disconnect the suction hose and discharge hose from the air conditioning compressor. When disconnecting the hoses from the compressor, immediately close the openings in the compressor and hoses with appropriate caps to prevent moisture from entering the air conditioning system.

- Turn out bolts and remove the compressor. When removing the compressor, be careful not to spill the compressor oil.

Installation

- If a new compressor is to be installed, adjust the compressor oil volume according to the procedure below, then install the compressor (keep the compressor oil balance in the air conditioning system).

- Drain the oil from the removed compressor and measure its volume (X).

- Drain the oil from the new compressor (Y), calculated using the formula below and install the compressor.

120 ml - X ml = Y ml

Notes. Y ml indicates the amount of compressor oil left in the pipes, condenser, evaporator, etc.

When replacing the following items at the same time as the compressor, subtract the estimated oil volume for each item from their Y ml volume and drain this volume from the new compressor.

Capacitor: 15ml

Vaporizer: 60 ml

Suction hose: 10 ml

Receiver: 10 ml

- Further installation is carried out in the reverse order of removal, taking into account the following.

- Replace O-rings and lubricate them with SUN PAG 56 compressor oil (see fig. 18.25).

- Install the compressor drive belt and adjust its tension.

Temperature sensor check

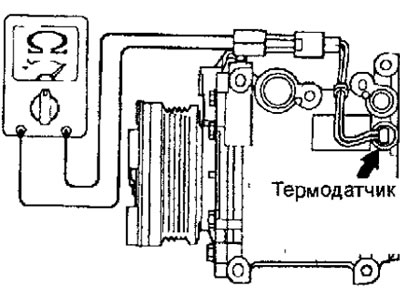

- With the air conditioning compressor off, use an ohmmeter to check the conductivity between the contacts of the temperature sensor connector (pic. 18.28). If there is no continuity, replace the temperature sensor.

Pic. 18.28. Checking the conductivity between the contacts of the sensor connector