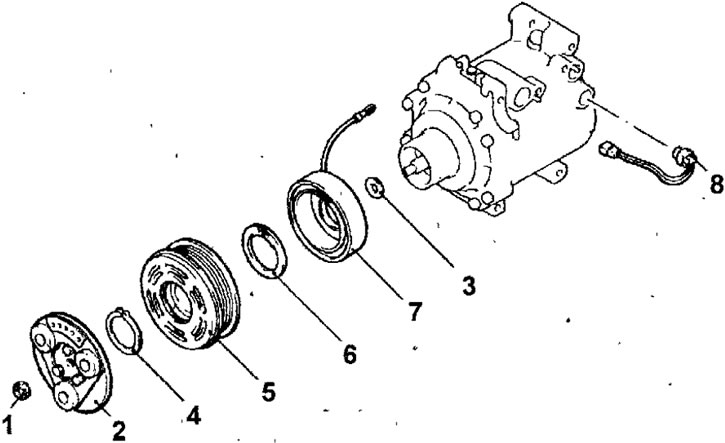

Pic. 18.29. Compressor electromagnetic clutch: 1 - nut; 2 - rotor disk; 3 - gasket; 4 - retaining ring; 5 - rotor; 6 - retaining spring ring; 7 - electromagnetic clutch coil; 8 - temperature sensor

Removing

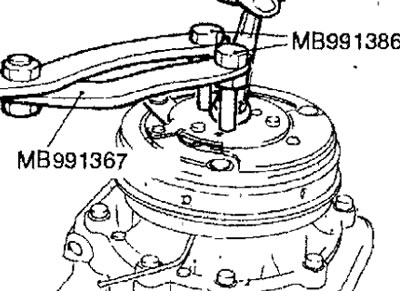

- Using special tools MB991367 and MB991386, holding the rotor disk from turning, unscrew the nut and remove the rotor disk (pic. 18.30).

Pic. 18.30. Unscrewing the nut securing the electromagnetic clutch plate

- Remove the circlip, magnetic clutch rotor and coil and gasket.

Installation

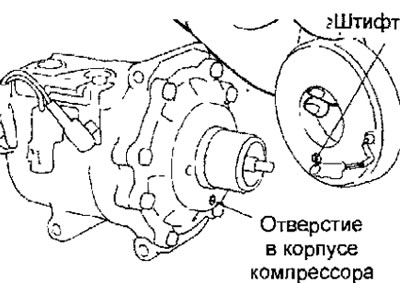

- When installing the magnetic clutch coil, align the pin of the coil with the hole in the compressor housing (pic. 18.31).

Pic. 18.31. Alignment of the magnetic clutch coil pin with the hole in the compressor housing

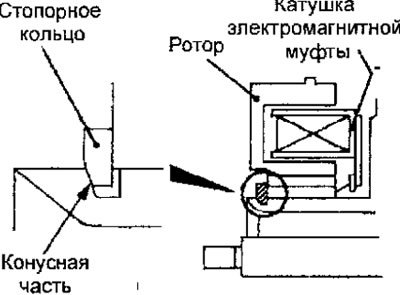

- Install the circlip so that the tapered surface faces the outside (pic. 18.32).

Pic. 18.32. Mounting position of the circlip

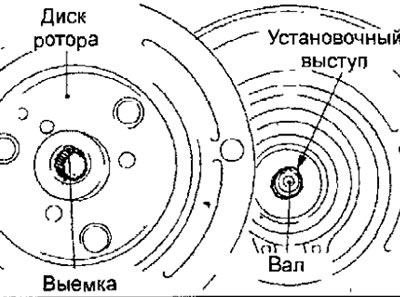

- Align the locating lug on the compressor shaft with the notch on the rotor disc and install the rotor disc on the shaft (pic. 18.33).

Pic. 18.33. Installing the plate on the compressor shaft

Using special tools MB991367 and MB991386, while holding the rotor disk from turning, screw the rotor disk fastening nut (pic. 18.30).

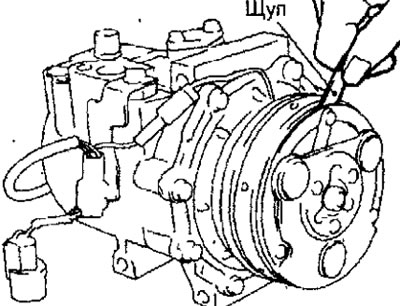

- Using a feeler gauge, measure the air gap of the electromagnetic clutch (pic. 18.34).

Pic. 18.34. Measuring the air gap of an electromagnetic clutch

Nominal clearance of the compressor electromagnetic clutch: 0.40-0.65 mm

Note. If the measured air gap of the compressor electromagnetic clutch does not correspond to the nominal one, adjust the gap by changing the number of shims