Warning. When removing the driver's airbag and coiled wire, follow the safety precautions when servicing the SRS system.

Removing

- On a right-hand drive vehicle, remove the relay box.

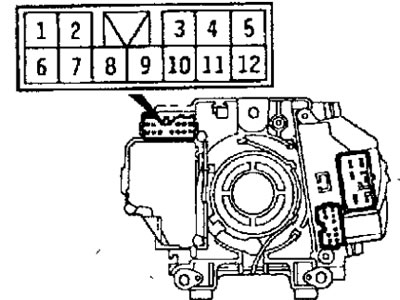

- Remove the multifunction stalk with integrated windshield wiper/washer switch and wiper relay.

- Disconnect and remove washer hose (pic. 17.65).

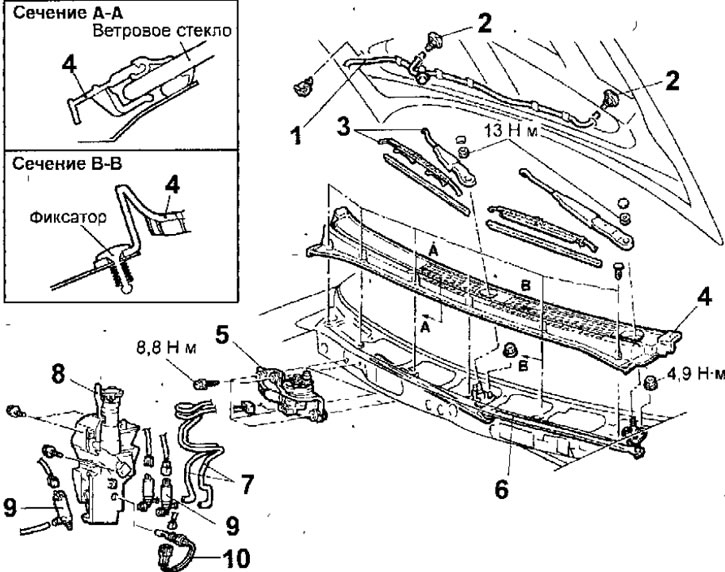

Pic. 17.65. Windshield wiper and washer: 1 - washer hose; 2 - washer sprayer; 3 - brush lever and windshield wiper brush assembly; 4 - ventilation panel; 5 - thrust wiper motor; 7 - washer hose; 8 - washer reservoir; 9 - washer motor; 10 - fluid level sensor in the washer reservoir

- Remove the washer nozzles.

- Remove caps from nuts, turn away nuts and remove levers of brushes and brushes of a cleaner of a windscreen.

- Loosen the screws by pulling up, release the latches and remove the ventilation panel.

- Turn away bolts of fastening of the electric motor of a screen wiper, disconnect an electric socket and remove the electric motor in gathering.

- Disconnect the levers from the electric motor and remove the wiper linkage (pic. 17.66).

Pic. 17.66. Disconnecting the linkage linkage from the motor crank

Warning. It is not recommended to disassemble the assembly of the lever mechanism and the electric motor without extreme necessity, since during assembly they are installed at a certain angle. If disassembly is necessary, pre-apply appropriate alignment marks.

- Drain the windshield washer fluid.

- Remove the front bumper.

- Disconnect the washer hoses from the windshield washer motors.

- Loosen the screws and remove the windshield washer reservoir,

- Disconnect the electrical connectors and remove the windshield washer motors from the reservoir.

- Remove the washer fluid level sensor from the reservoir.

Installation

- Installation is carried out in the reverse order of removal, taking into account the following.

- The movement of the left and right arms of the windshield brushes are different, so when installing them, take into account their position according to the installation marks.

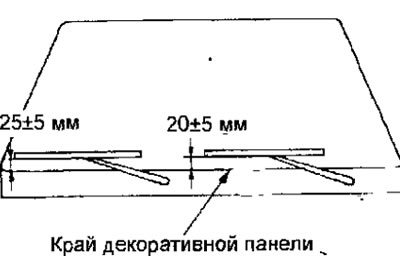

- Install the wiper blades in the position shown in Figure 17.67.

Pic. 17.67. Installation position of the windshield wiper blades.

Checking the windshield wiper switch

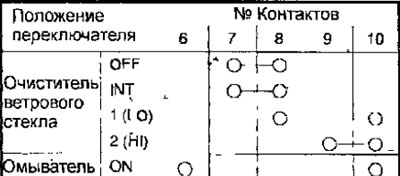

- Using an ohmmeter, check the continuity between the connector pins at different positions of the windshield wiper switch (pic. 17.68).

Pic. 17.68. Pin assignment of the windshield wiper switch connector

Checking the windshield wiper motor

- The windshield wiper motor must be installed in the vehicle and the wiring harness electrical connector disconnected from the motor.

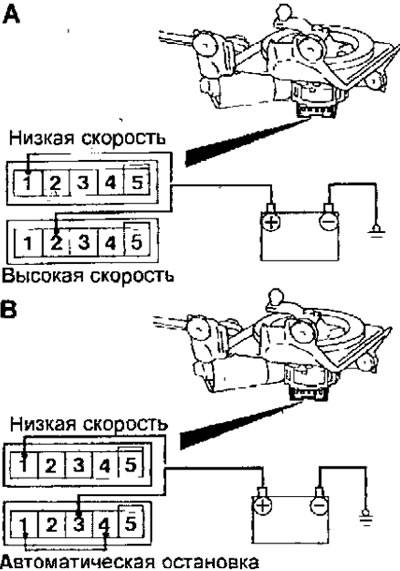

- With additional wires, connect the battery terminals to the engine connector contacts as shown in Figure 17.69 (A), and check the operation of the wiper at low and high speeds.

- With additional wires, connect the battery terminals to the engine connector contacts as shown in Figure 17.69 (IN), and leave the engine running at low speed. With the engine running, disconnect the positive battery cable and stop the engine.

- With additional wires, connect the battery terminals to the contacts of the engine connector, and also close contacts 1 and 4 of the connector as shown in Figure 17.69 (IN), and check that the motor stops in its original position.

Pic. 17.69. Connecting the battery to the engine connector pins to test the operation of the wiper at low and high speeds (A) and stop the wiper motor in its original position (IN)

Checking the windshield washer motor

- When checking, the tank must be installed in the car and filled with liquid.

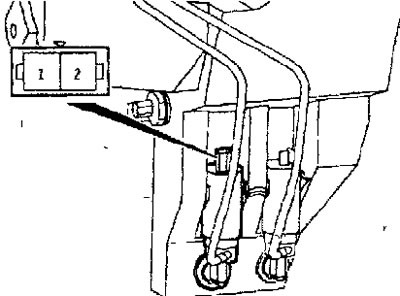

- With additional wires, connect the positive terminal of the battery to pin 2 of the connector and the negative terminal to pin 1 of the connector, while the liquid should be sprayed onto the windshield (pic. 17.70).

Pic. 17.70. Checking the windshield washer motor

Checking the fluid level sensor in the washer reservoir

- Remove the washer fluid level sensor.

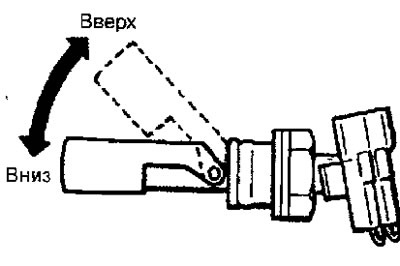

- Connect an ohmmeter to the contacts of the fluid level sensor connector in the washer reservoir (pic. 17.71).

Pic. 17.71. Checking the fluid level sensor in the washer reservoir

- Make sure that when the float is moved down, the circuit is closed, and when the float is moved up, the circuit is opened.

- Checking the position of the windshield sprayers

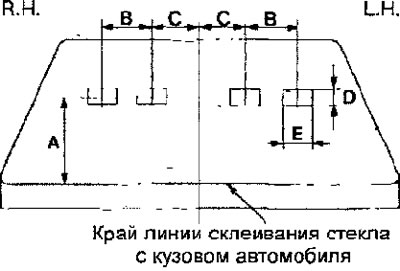

- By moving the sprayers in the nests, achieve the correct spraying of the liquid jets on the windshield, in accordance with the one shown in Figure 17.72.

Pic. 17.72. Checking the position of the windshield sprayers: A - 270 mm; B - 250 mm; C, - 100 mm; D - 50 mm; E - 70 mm