Removing

1. Drain the gearbox oil.

2. Remove the lower protective cover.

3. Remove the air filter assembly.

4. Remove the battery and its tray.

5. Remove the fuel vapor canister.

6. Remove drafts of a gear change in gathering.

7. Remove the air pipe from the aftercooler (models since 1997).

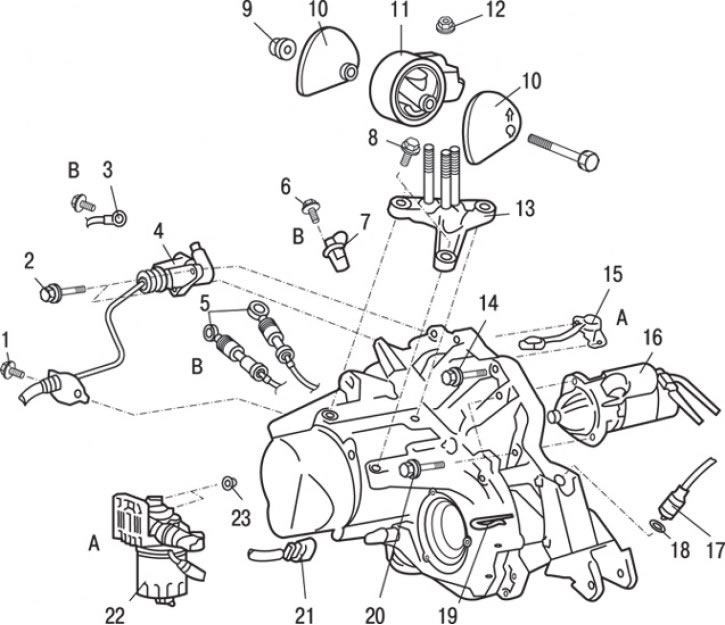

Pic. 11.13. Elements of fastening of gearboxes: A - only the F5MR3 gearbox; B - only F5MV1 gearbox; 1 - nut (48 Nm); 2 - bolt (30 Nm); 3 - wire «masses»; 4 - clutch slave cylinder; 5 - transmission control cables (F5MV1); 6 - bolt (10 Nm); 7 - engine crankshaft position sensor (F5MV1); 8 - bolt (56 Nm); 9 - nut (118 Nm); 10 – a lock flange of a transmission; 11 – an arm of a support of a transmission; 12 - nut (62 Nm); 13 – the bottom bracket of a support of a transmission; 14 – the top bolts of fastening of a transmission (50 Nm); 15 - vehicle speed sensor (F5MR3); 16 - starter; 17 – speedometer cable connection; 18 - annular sealing gasket; 19 - cotter pin; 20 - bolt (49 Nm); 21 – a socket of the switch of lanterns of a backing; 22 - fuel filter assembly (F5MR3); 23 - nut (25 Nm)

8. Remove cotter pin 19 (pic. 11.13), disconnect the cable 17 of the speedometer drive from the gearbox and remove the O-ring 18.

9. Disconnect an electric socket 21 of the switch of lanterns of a backing.

10. Disconnect cables 5 transmission control (gearbox F5MV1).

11. Turn away a bolt and disconnect a wire 3 «masses» (gearbox F5MV1).

12. Turn away a bolt and remove the gauge 7 of provision of a cranked shaft of the engine (gearbox F5MV1).

13. Turn away bolts, remove a starter 16 together with the wires attached to it and fix it in a motor compartment.

14. Remove the slave cylinder 4 of the clutch without disconnecting the pipes and hoses of the hydraulic drive, and tie it to the vehicle chassis.

15. Disconnect the vehicle speed sensor electrical connector (gearbox F5MR3).

16. Turn away the top connecting bolts 14 of a transmission in gathering.

17. Remove the bolts and disconnect the fuel filter assembly from the vehicle body, but do not disconnect the fuel hoses from it (gearbox F5MR3).

18. Gently raise the gearbox with a hydraulic jack, then unscrew the nut, remove the bolt, remove the gearbox locking flanges and disconnect the bracket 11 of the gearbox support.

19. Install a special tool on the car (motor hoist with manual hoist and traverse) to support the engine.

20. Turn away bolts of fastening of the bottom arm 13 of a support of a transmission.

21. Raise the car on a lift.

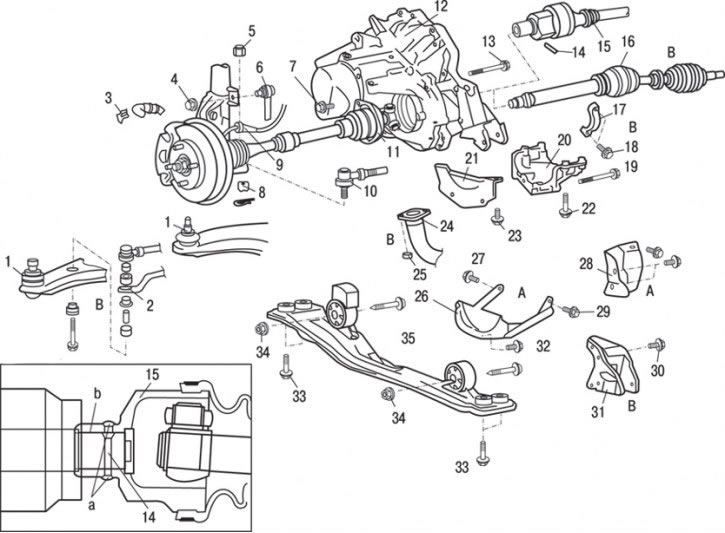

Pic. 11.14. Fastening elements for F5MR1 and F5MR2 gearboxes: A - only the F5MR3 gearbox; B - only F5MV1 gearbox; a - the place of lubrication; b - the place of application of the sealant; 1 - connection of the pin of the ball joint of the lower suspension arm with the steering knuckle; 2 - stabilizer bar; 3 – a clamp of a brake hose; 4 - nut (44 Nm); 5 - nut (59–71 Nm); 6 – connection of the stabilizer of cross stability; 7 - bolt (25 Nm); 8 - nut (15–33 Nm); 9 – a socket of the gauge of frequency of rotation of a wheel (vehicles with ABS); 10 - connection of the pin of the ball joint of the tie rod end with the steering knuckle; 11 - connection of the left wheel drive shaft; 12 - gearbox assembly; 13 – the lower connecting bolts of a transmission (50 Nm); 14 - split pin; 15 - connection of the drive shaft of the left wheel; 16 - connection of the drive shaft of the right wheel; 17 - bearing bracket; 18 - bolt (25 Nm); 19 - bolt (48 Nm); 20 – an arm of fastening of a transmission (SOHC engine); 21 - front cover of the clutch housing (SOHC engine); 22 - bolt (22–25 Nm); 23 - bolt (10–12 Nm); 24 - receiving exhaust pipe; 25 - bolt (25 Nm); 26 - curved spacer; 27 - bolt (40 Nm); 28 - thermal protection; 29 - bolt (39 Nm); 30 - bolt (50 Nm); 31 - rear support of the power unit; 32 - bolt (22 Nm); 33 - bolt (69 Nm); 34 - bolt (59 Nm); 35 - longitudinal beam assembly

22. Turn away nuts and disconnect drafts of the stabilizer of cross-section stability 6 (pic. 11.14).

23. Remove the clamp 3 fastening the brake hose.

24. Disconnect connector 9 of the wheel speed sensor (vehicles with ABS).

25. Using a special tool, loosen the ball joint pin nut and use a puller to disconnect the tie rod end from the steering knuckle, then finally unscrew the nut.

Attention! Hang the puller from a wire or cord to prevent the puller from jumping off.

26. Using a special tool, loosen the nut 1 of the ball joint pin of the lower suspension arm and use a puller to disconnect the lower suspension arm from the steering knuckle, then finally unscrew the nut.

27. Turn away nuts and remove the stabilizer 2 cross-section stability (gearbox F5MV1).

28. Turn away bolts and remove a longitudinal beam 35 in gathering.

29. Disconnect the wheel drive shaft along with the hub and steering knuckle.

30. Turn away bolts and remove thermal protection (gearbox F5MR3).

31. Suspend the removed drive shaft of the wheel inside the wheel arch with a wire so as to prevent a strong kink in the CV joints.

32. Remove the sealant and, using a punch, knock out the split pin 14.

33. Disconnect the drive shaft 15 together with the hub and steering knuckle.

34. Suspend the removed wheel drive shaft inside the wheel arch with a wire so as to prevent a strong bend in the CV joints.

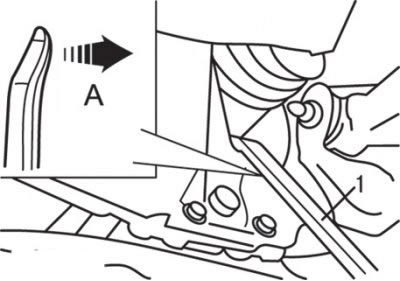

Pic. 11.15. Removing the right wheel drive shaft: A - the location of the gearbox; 1 - mount

35. To disconnect the drive shaft, insert a pry bar between the gearbox housing and the shaft as shown in fig. 11.15 (gearbox F5MV1).

Attention! Do not disconnect the drive shaft from the steering knuckle and hub. Always use a pry bar, otherwise the tripod CV joint will be damaged (T.J.) drive shaft

36. Suspend the removed wheel drive shaft with a wire so as to prevent a strong kink in the CV joints (gearbox F5MV1).

37. Cover the gearbox with a rag to prevent foreign particles and objects from getting inside the gearbox.

38. Carefully lift the gearbox with a hydraulic jack and remove the gearbox support bracket (gearbox F5MV1).

39. Turn away bolts and remove bolts of fastening of an arm 17 (see fig. 11.14) (gearbox F5MV1).

40. Turn away nuts and disconnect a reception exhaust pipe 24 (gearbox F5MV1).

41. Turn away bolts and remove a curved spacer (gearbox F5MR3).

42. Remove the bolts and remove the rear support 31 of the power unit (gearbox F5MV1).

43. Turn away bolts and remove an arm of fastening 20 of a transmission (SOHC engine).

44. Remove the bolts and remove the front cover 21 of the clutch housing (SOHC engine).

45. Turn away the bottom connecting bolts 13 of a transmission.

46. Remove gearbox 12 as an assembly.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. After applying multipurpose grease to the spline of the drive shaft, align the split pin hole at the end of the shaft with the split pin hole at the transmission end of the shaft, and then install the drive shaft.

2. If the split pin hole is slightly misaligned, rotate the drive shaft 180°and then try to install it again.

Attention! Because the drive shaft has an odd number of splines, the pin hole will be offset by half the diameter if the shaft is rotated 180°.

3. Apply Mitsubishi genuine part MD970389 or similar sealant to the split pin and then insert it into the drive shaft.

4. After installing the pin, apply sealant to both sides of the pin hole to completely seal them.

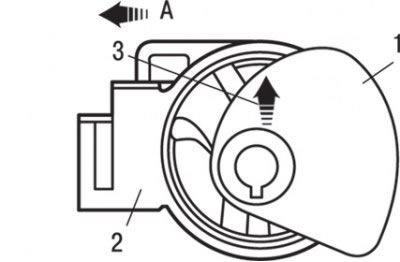

Pic. 11.16. Installing the gearbox retaining flange: A - the location of the engine; 1 – a stopper of a support of transmission; 2 – an arm of a support of transmission; 3 - arrow

5. Install the gearbox support limiter so that the arrow on the flange points in the direction shown in fig. 11.16.

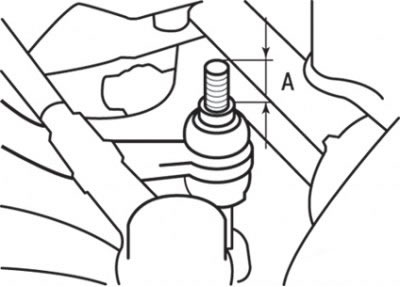

Pic. 11.17. Protrusion distance of the stabilizer mounting bolt: A = 22 mm

6. Tighten the self-locking nut so that the stabilizer mounting bolt protrudes above the nut as shown in fig. 11.17 (gearbox F5MV1).

7. Install the shift rod assembly.

8. Install the canister.

9. Install the battery.

10. Install the air filter assembly.

11. Install the bottom guard.

12. Fill in gear oil.

13. Check the operation of the gear lever.

14. Check the operation of the speedometer.