Removing

1. Drain the transmission fluid.

2. Remove the lower protective cover.

3. Remove the air filter assembly.

4. Remove the battery and its tray.

5. Remove the fuel vapor canister.

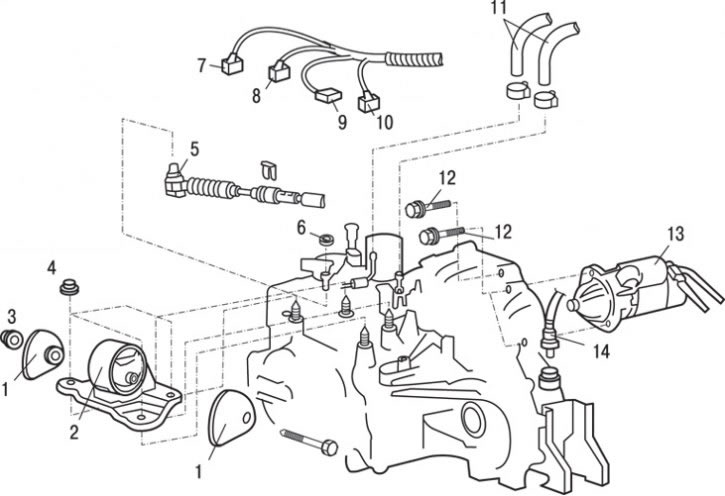

Pic. 12.22. Fastening elements of an automatic transmission: 1 – a stopper of a support of a transmission; 2 – an arm of a support of a transmission; 3 - nut (118 Nm); 4 - nut (98 Nm); 5 - tip of the cable connecting the gear selector lever with the control valve block; 6 - nut (13 Nm); 7 – a socket of the block of electromagnetic valves; 8 – a socket of the switch of the selector of a transmission; 9 - speed sensor connector «IN»; 10 - speed sensor connector «A»; 11 – connection of hoses of the transmission oil cooling system; 12 – the top bolts of fastening of a transmission (48 Nm); 13 - starter; 14 – speedometer drive cable connection

6. Turn away a nut and disconnect a cable 5 (pic. 12.22), connecting the selector lever to the control valve block.

7. Loosen the clamps and disconnect the hoses of the working fluid cooling system.

8. Disconnect electrical connectors 10, 9, 8, 7 speed sensors «A» And «IN», selector switch and solenoid valve block respectively.

9. Turn away a nut and disconnect a cable of a drive of a speedometer.

10. Turn away bolts, remove a starter 13 together with the wires attached to it and fix it in a motor compartment.

11. Turn away the top connecting bolts 12 fastenings of a transmission in gathering.

12. Gently raise the gearbox with a hydraulic jack, then unscrew the nut, remove the bolt, remove the gearbox locking supports and disconnect the gearbox support bracket 2.

13. Install a special tool on the car (motor hoist with manual hoist and traverse) to support the engine.

Attention! Bolts marked with (*), must first be pre-tightened, fully tighten them to the specified values only with the vehicle standing on the ground, unladen.

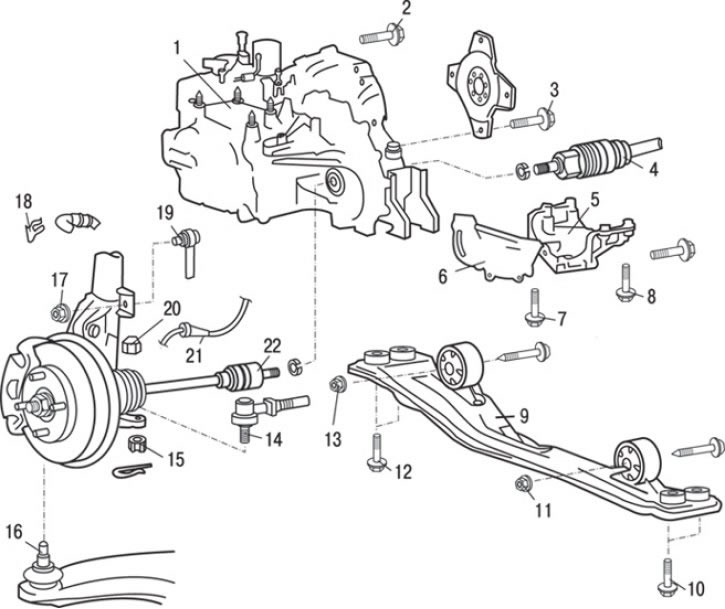

Pic. 12.23. Automatic transmission: 1 - gearbox assembly; 2 – the lower bolts of fastening of a transmission (48 Nm); 3 – bolts of fastening of a plate of a drive of the hydrotransformer (45–52 Nm); 4 - right drive shaft; 5 - gearbox support; 6 - flywheel housing shield; 7 - bolt (10–12 Nm); 8 - bolt (22–25 Nm); 9 - central beam; 10 - bolt (69 Nm); 11 – bolt* (59 Nm); 12 - bolt (69 Nm); 13 – bolt* (59 Nm); 14 – the hinge of a tip of steering draft; 15 - nut (15–33 Nm); 16 - ball bearing of the lower suspension arm; 17 - nut (44 Nm); 18 – bracket of a brake hose; 19 - stabilizer connection; 20 - nut (58–71 Nm); 21 - speed sensor connector (vehicles with ABS); 22 - left drive shaft

14. Turn away nuts and disconnect drafts 19 (pic. 12.23) anti-roll bar.

15. Remove the bracket 18 of the brake hose.

16. Disconnect the wheel speed sensor connector 21 (vehicles with ABS).

17. Using a special tool, loosen the ball joint pin nut and use a puller to disconnect the tie rod end from the steering knuckle, then finally unscrew the nut.

Attention! Hang the puller from a wire or cord to prevent the puller from jumping off.

18. Using a special tool, loosen the nut of the ball joint pin of the lower suspension arm and use a puller to disconnect the lower suspension arm from the steering knuckle, then finally unscrew the nut.

19. Turn out bolts and remove a central beam 9 in gathering.

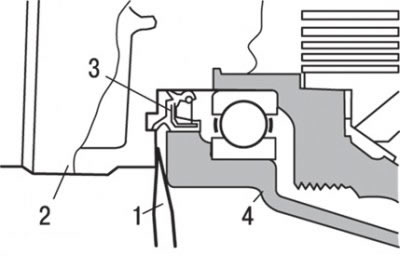

Pic. 12.24. Removing the drive shaft: 1 - mount; 2 - drive shaft; 3 - stuffing box; 4 - gearbox housing

20. To remove the drive shaft, insert a pry bar between the shaft and the gearbox housing as shown in fig. 12.24.

Attention! Do not remove the hub and steering knuckle from the drive shaft.

Attention! To avoid damaging the CV joint, always use a pry bar.

Attention! Do not insert the pry bar too deep to avoid damaging the seal.

21. Tie up the removed drive shaft with a cord so that there are no large bends in the CV joints.

22. To protect against the ingress of dirt and foreign particles into the gearbox housing, close the hole with a special cover.

23. Turn away bolts and remove a support 5 (see fig. 12.23) gearboxes.

24. Turn away bolts and remove a guard of a casing 6 flywheel.

25. Jack up the transmission slightly.

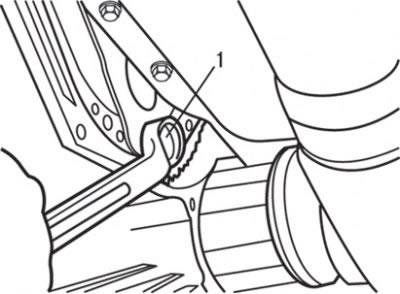

Pic. 12.25. Loosening bolts (1) torque converter drive plate

26. Turning the crankshaft of the engine, unscrew the bolts securing the torque converter drive plate (pic. 12.25).

Attention! When installing the drive shaft, be careful not to damage the seal lip with the sharp edges of the shaft spline.

27. Press the torque converter towards the gearbox so that it does not remain on the engine.

28. Turn out the lower bolts of fastening of a transmission and lower it on a floor.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

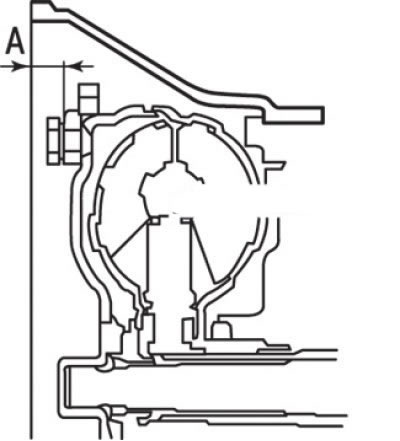

Pic. 12.26. Correct installation of the torque converter in the gearbox housing: A = 12.2 mm

1. When installing the torque converter in the gearbox housing, maintain dimension A (pic. 12.26) and install the gearbox assembly on the engine.

2. Temporarily install the drive shaft, ensuring the alignment of the drive shaft and the mounting hole of the gearbox housing when installing the CV joint housing.

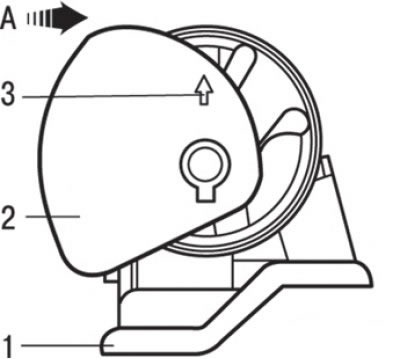

Pic. 12.27. Installing the gearbox retaining flange: A - the location of the engine; 1 – a stopper of a support of transmission; 2 - transmission support limiter; 3 - arrow

3. Establish a stopper of a support of a transmission so that the arrow was directed as shown in fig. 12.27.

4. Fill in the working fluid.

5. Install the bottom guard.

6. Install the fuel vapor canister.

7. Install the battery.

8. Install the air filter assembly.

9. Check up operation of the selector lever.

10. Check the operation of the speedometer.