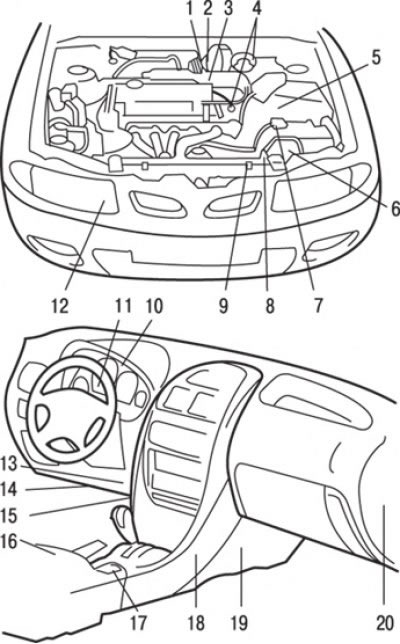

Pic. 12.1. Location of automatic transmission controls: 1 - throttle position sensor (vehicles without TCL); 2 – the sensor of full closing throttle; 3 - accelerator pedal position sensor (vehicles with TCL); 4 - engine crankshaft speed sensor; 5 – automatic gearbox output shaft speed sensor; 6 - block of electromagnetic valves; 7 – automatic transmission selector switch; 8 - automatic transmission oil temperature sensor; 9 - speed sensor of the input shaft of the automatic transmission; 10 - control lamp of the selected range; 11 - vehicle speed sensor; 12 - double pressure sensor; 13 - diagnostic connector; 14 – the sensor of inclusion of a stoplight; 15 - throttle full opening sensor; 16 - electronic control unit TCL (TCL-ECU); 17 – automatic transmission mode switch; 18 - electronic control unit for automatic transmission (AT-ECU); 19 – automatic transmission control relay; 20 - electronic engine control unit (Engine-ECU)

A four-speed automatic transmission is installed on some cars. Since the automatic transmission is a complex unit, its repair must be carried out at a service station using special equipment. The arrangement of elements of management of an automatic transmission is resulted on fig. 12.1.

Diagnostics

Transmission malfunctions can be caused by the following reasons:

- poor-quality adjustment;

- malfunctions in the hydraulic system;

- malfunctions in the mechanical system;

- malfunctions in the computer or the electrical circuit of the computer.

First of all, check the level and condition of the oil in the gearbox and adjust the linkages.

Preliminary control

1. Take a test drive to warm up the transmission.

2. Check up level of a working liquid in a transmission.

3. Check the engine idle speed.

4. Check up freedom of movement of a cable of an accelerator and if necessary adjust it.

5. Check the operation of the gear selection mechanism.

6. Check up absence of leak in places of installation of linings and sealing rings in a transmission.

Diagnostic functions

In the event of a malfunction in one of the following elements that ensure the normal operation of the automatic transmission (AKP), position indicator lamp «N» selector lever starts flashing at a frequency of approximately 1 Hz. In this case, it is necessary to check the fault codes.

Elements whose malfunction causes the position lamp to flash «N» automatic transmission selector lever:

- engine crankshaft speed sensor;

- input shaft speed sensor;

- output shaft speed sensor;

- one of the solenoid control valves;

- shift timing mismatch.

Attention! If the mode indicator «N» flashes at a frequency of approximately 2 Hz (more than 1 Hz), this means that the temperature of the fluid in the automatic transmission is too high. Park the vehicle in a safe place and wait until the mode indicator light «N» will go out.

Fault codes can be read either using a special tool MUT-II, or using a position lamp «N» selector lever for automatic transmission.