2. Disconnect the high pressure fuel hose from the high pressure fuel pump.

Attention! Cover the hose connection with a rag to avoid fuel splashing due to residual pressure in the high pressure line.

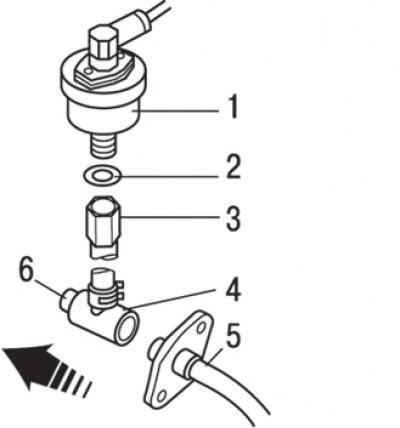

Pic. 8.3. Special tool for measuring the pressure between the high pressure fuel hose and the high pressure fuel pump: 1 - to the high pressure fuel pump; 2 - gasket; 3 - special tool МВ991637; 4 - special tool МВ998709; 5 - special tool МВ998742; 6 - to the high pressure fuel hose

3. Disconnect the coupler and bypass bolt from the hose adapter and connect the special tool to the hose adapter instead (pic. 8.3).

4. Install special tool (for pressure measurement) between the high pressure fuel hose and the high pressure fuel pump.

5. Connect the fuel pressure sensor to the fuel pressure gauge with a gasket between them.

6. Connect the fuel pressure sensor wire to the power supply (cigarette lighter) and to the MUT-II instrument.

7. When using a pressure gauge, do the following:

- install the pressure gauge on a special tool for measuring pressure, placing an o-ring or gasket between them;

- install the special tool with gauge assembly between the high pressure fuel hose and the high pressure fuel pump.

8. Connect the MUT-II device to a diagnostic socket.

9. Turn the ignition key to position «ON» («ON») (but don't start the engine).

Attention! Always turn off the ignition before connecting or disconnecting the MUT-II.

10. Select the required menu item «Actuator test» (Checking actuators) MUT-II to actuate the low pressure fuel pump (from the side of the fuel tank). Make sure there are no leaks at the connections.

11. End the mode «Actuator test» (Checking actuators) or turn the ignition key to position «OFF» («OFF»).

12. Start the engine and let it idle.

13. While the engine is idling, measure the fuel pressure (nominal fuel pressure - about 324 kPa).

14. Make sure that the fuel pressure at idle does not drop even after several presses on the accelerator pedal.

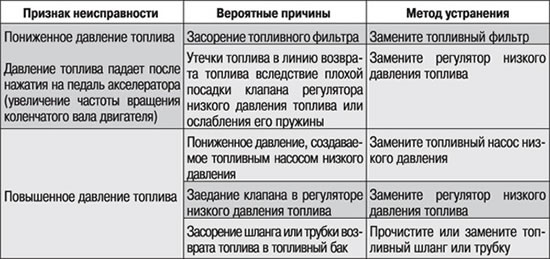

15. If the fuel pressure does not correspond to the required one, determine the malfunctions and eliminate them in accordance with the table. 8.1.

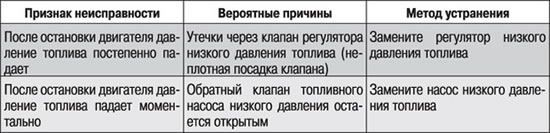

16. Turn off the engine and check if there is a change in the pressure gauge. The power supply system is operational if the pressure in the fuel line does not decrease within 2 minutes. If the pressure decreases, then determine the malfunctions and eliminate them in accordance with the table. 8.2.

17. Relieve residual pressure in the fuel line.

18. Disconnect the fuel pressure gauge and special tool from the high pressure fuel pump.

Table 8.1. Definition of malfunctions and methods of their elimination in the case when the fuel pressure does not correspond to the required one

Table 8.2. Definition of malfunctions and methods of their elimination in case of decrease in pressure of fuel

Attention! Cover the hose connections with a rag to avoid fuel splashing due to residual pressure in the fuel line.

19. Replace the O-ring with a new one installed on the high pressure fuel hose. Before installing the gasket, apply a layer of engine oil to its surface.

20. Connect the high pressure fuel hose to the high pressure fuel pump and tighten the flange mounting bolts to the correct torque.

21. Check for fuel leaks from the connections.

22. Disconnect the MUT-II.