Removing

To remove, perform the following steps in sequence.

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the motor protective cover.

3. Relieve fuel pressure (fuel splash prevention).

Fuel pressure sensor

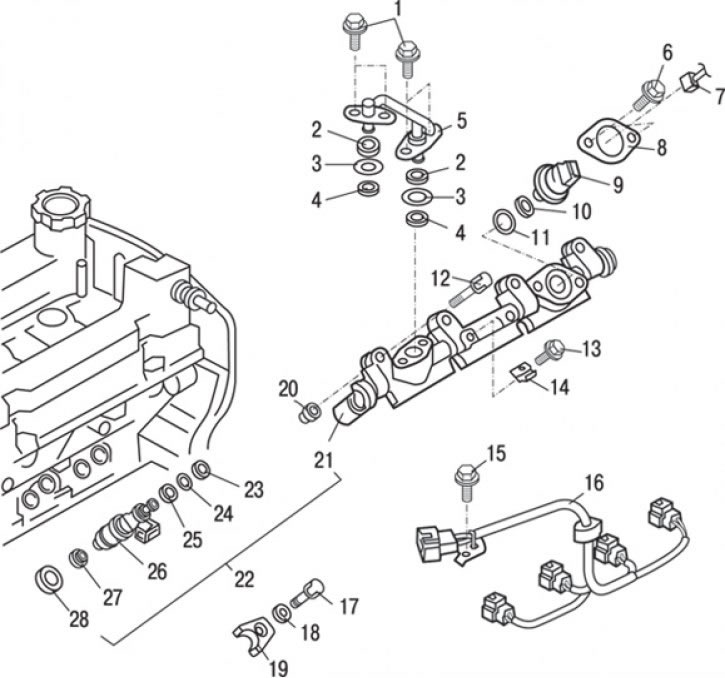

Pic. 8.12. Nozzles: 1 - bolt (10–13 Nm); 2 - support ring «IN»; 3 - annular gasket; 4 - support ring «A»; 5 – fuel tube; 6 - bolt (22–26) N·m; 7 – a socket of the gauge of pressure of fuel; 8 - flange; 9 - fuel pressure sensor; 10 - support ring; 11 - annular gasket; 12 - bolt (11–13 Nm); 13 - bolt (12–14 Nm); 14 - support bracket for the injector wiring harness; 15 - bolt (10–14 Nm); 16 - wiring harness for injectors; 17 - bolt (21–25 Nm); 18 - washer; 19 - nozzle holder; 20 - insulator; 21 - fuel rail; 22 - fuel rail and nozzle assembly; 23 - support ring «A»; 24 - annular gasket; 25 - support ring «IN»; 26 - nozzle; 27 - figured washer; 28 - nozzle gasket

1. Disconnect the fuel pressure sensor connector 7 (pic. 8.12).

Pic. 8.13. Marking before flange removal: 1 - flange; 2 - fuel pressure sensor; 3 - installation marks

2. When reusing the fuel pressure sensor, make a match mark on the flange and on the sensor (pic. 8.13).

Attention! The flange ensures the reliability of the fuel pressure sensor installation, taking the appropriate shape when it is fixed. Therefore, before removing the sensor (and if it is reused) installation marks help with its subsequent installation. If a new fuel pressure sensor is installed, it must be replaced complete with a flange.

3. Remove fuel pressure sensor 9, O-ring 11 and support ring 10 (see fig. 8.12).

Nozzles

1. Remove the air filter.

2. Remove the throttle body.

3. Remove the intake manifold.

4. Unscrew bolts, disconnect sockets and remove a plait of wires of atomizers 16.

5. Unscrew the bolts and remove the injector harness support bracket 14.

6. Unscrew the bolts and remove the fuel pipe 5.

7. Remove support ring «A» 4

8. Remove O-ring 3.

9. Remove support ring «IN» 2

10. Unscrew the bolt and remove the washer 18 and nozzle holder 19.

11. Unscrew bolts and remove a fuel stage with atomizers in gathering, without separating them.

Note. Be careful when removing the fuel rail - do not drop the injectors.

12. Turn away a bolt and remove an insulator 20.

13. Remove the nozzle gaskets 16, nozzles 26, curly washers 27, support ring «A» 23, O-ring 24 and support ring «IN» 25.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

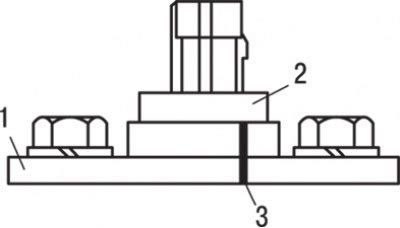

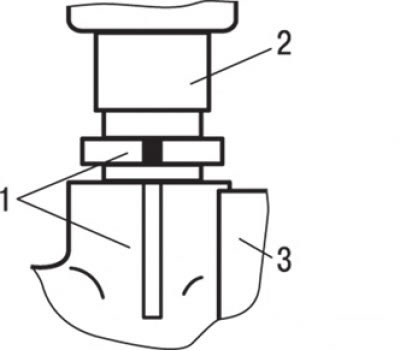

Pic. 8.9. Installation of support rings and gaskets: 1 - support ring «A»; 2 - support ring «IN»; 3 - annular gasket; 4 - beveled surface

1. Install support rings and O-ring as shown in fig. 8.9.

Attention! Install support ring «IN» chamfered surface from the reverse side of the O-ring (see fig. 8.9).

2. Make sure the support ring is installed correctly «A» (support ring outside diameter «A» equal to 14.8 mm). Do not confuse it with the fuel pressure sensor support ring.

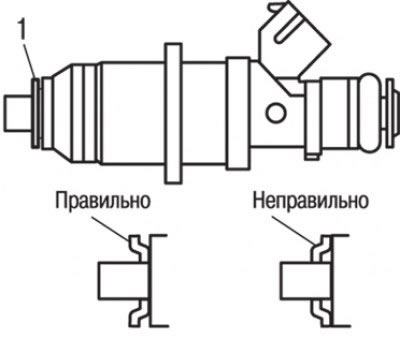

Pic. 8.14. Installing a figured washer (1)

3. Apply grease to the surface of the shaped washer to prevent it from falling off when installing the nozzle, install it on the nozzle as shown in fig. 8.14.

Attention! The figured washer is not reused.

4. Apply a small amount of clean engine oil to the O-ring.

Attention! Be careful not to let engine oil get inside the fuel rail.

5. Carefully, trying not to damage the O-ring, and turning the nozzle left and right, connect it to the fuel rail. At the end of this operation, make sure that the nozzle turns easily in its seat.

6. If the nozzle turns in its seat with jamming, then it is possible that «bitten» ring gasket. Remove the nozzle, check the condition of the O-ring (replace if damaged), reconnect the injector to the fuel rail and recheck the build quality (the nozzle should turn easily in its seat).

Pic. 8.15. Alignment marks (1) nozzles (2) and fuel manifold (3)

7. Align the injector and fuel rail alignment marks (pic. 8.15).

8. Install the injector gasket and insulator into the cylinder head.

9. Install the fuel rail assembly with injectors into the block head and fasten it by hand with bolts.

10. Install the nozzle holder and washer and tighten it to a torque of 21–25 Nm.

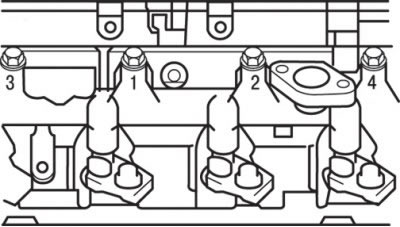

Pic. 8.16. The sequence of tightening the bolts of the fuel manifold assembly and injectors

11. Tighten bolts of fastening of a fuel stage in gathering with atomizers the moment of 11–13 Н·м according to resulted on fig. 8.16 is fine.

12. Install support rings and O-ring (see fig. 8.9).

Attention! Install support ring «IN» chamfered surface from the reverse side of the O-ring (see fig. 8.9).

13. Make sure the support ring is installed correctly «A» (support ring outside diameter «A» equal to 14.8 mm). Do not confuse it with the fuel pressure sensor support ring.

14. Apply a small amount of clean engine oil to the O-ring.

Attention! Do not allow engine oil to enter the high pressure fuel pump or fuel manifold.

15. Install the fuel pipes at a right angle into the channels of the high pressure fuel pump. Install the tubes carefully, avoiding twisting them, then tighten the bolts to a torque of 11–13 Nm.

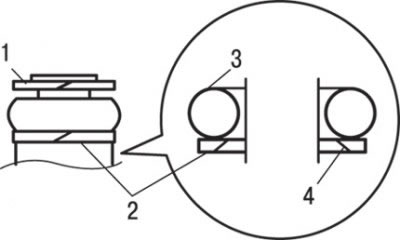

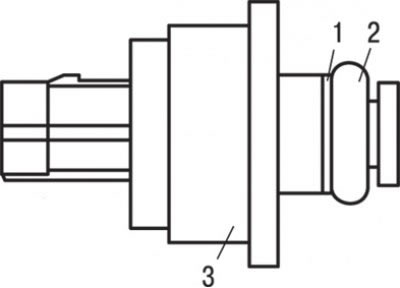

Pic. 8.17. Installing the support ring and O-ring: 1 - support ring; 2 - annular gasket; 3 - fuel pressure sensor

16. Install support ring and O-ring as shown in fig. 8.17.

Attention! Be careful not to confuse this o-ring with the o-ring «A» for injector or for fuel pipe (the outside diameter of this o-ring is 15.1mm).

17. Apply a small amount of clean engine oil to the fuel pressure sensor O-ring.

Attention! Do not allow engine oil to enter the fuel manifold.

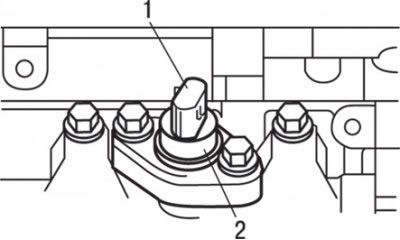

Pic. 8.18. Location of product label (2) when installing a fuel pressure sensor (1)

18. Install the fuel pressure sensor so that its product label with the number is located as shown in fig. 8.18. If the fuel pressure sensor is reused, then before removing it, it is necessary to make installation marks on its body and flange to facilitate subsequent installation.

Attention! If a new fuel pressure sensor is installed, replace it complete with flange.

19. Install the engine cover.

20. Check the tightness of the power system.

21. Bleed air from the high pressure fuel line.