Removing

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the hood.

3. Drain the coolant from the engine cooling system.

4. Remove a transmission.

5. Remove the radiator.

6. Remove the intake hose and air filter.

7. Remove the air duct for the intercooler of the charge air.

8. Remove the protective cover.

9. Remove a reception pipe of system of release of the fulfilled gases.

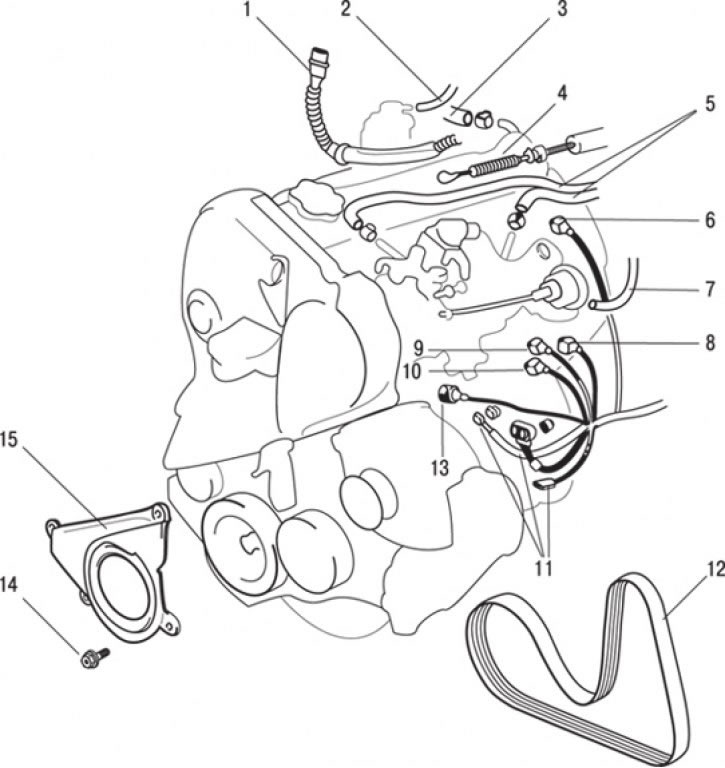

Pic. 4.31. Connecting connectors and hoses to the F8QT engine: 1 – a socket of the relay of glow plugs; 2 – connection of vacuum hoses; 3 – connection of a hose of the vacuum amplifier of brakes; 4 - connection of the injection pump control cable; 5 – connections of fuel hoses; 6 - connector for the injector needle lift sensor; 7 – connection of vacuum hoses; 8 - immobilizer connector; 9 – a socket of the gauge of the lever of a load; 10 – a socket of the electromagnetic valve of dispensing of fuel; 11 - generator connectors; 12 – a belt of a drive of auxiliary units; 13 – a socket of the gauge-switch of pressure of oil; 14 - bolt, 9 Nm; 15 - front casing From the timing belt

10. Disconnect vacuum hoses 2 and 7 (pic. 4.31).

11. Loosen the clamp and remove the hose 3 of the vacuum brake booster.

12. Disconnect the connectors of the generator 11, oil pressure switch 13, load lever sensor 9, fuel metering solenoid valve 10, immobilizer 8, injector needle lift sensor 6 and glow plug relay.

13. Disconnect the cable 1 of the injection pump control 4.

14. Loosen the clamps and remove the fuel hoses 5.

15. Turn away bolts and remove a forward casing 15 of a belt of a drive of the gas-distributing mechanism.

16. Remove the drive belt 12.

Attention! Field connections marked with the icon (*), must first be installed and pre-tightened, and only after the engine is fully supported by the car body, fully tightened to the rated torque.

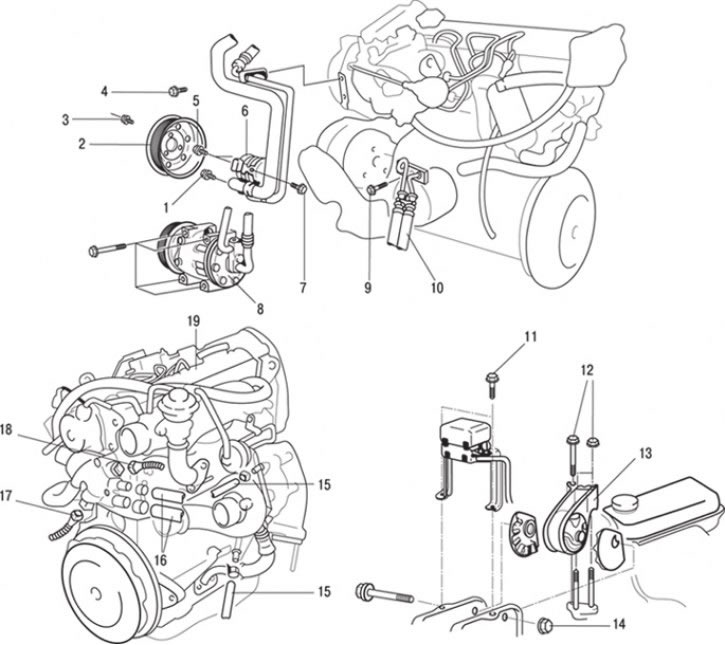

Pic. 4.32. F8QT engine: 1 - bolt, 60 Nm; 2 – a pulley of the pump of the amplifier of a steering; 3 - bolt, 10 Nm; 4 - bolt (cars without air conditioning), 25 Nm; 5 - bolt, 60 Nm; 6 - power steering pump; 7 - bolt, 60 Nm; 8 - air conditioner compressor; 9 - bolt, 12 Nm; 10 – connection of hoses of an oil cooler of the engine (cars with air conditioning); 11 - bolts (cars with air conditioning), 10 Nm (flange bolt), 6 Nm (bolt with washer); 12 - bolt, 50 Nm; 13 - engine support bracket; 14 - bolt, 90 Nm; 15 – connection of hoses of the engine cooling system; 16 – connection of heater hoses; 17 – a socket of the gauge of temperature of a cooling liquid (on the temperature gauge); 18 – a socket of the gauge of temperature of a cooling liquid; 19 - engine assembly

17. Turn out bolts and remove hoses 10 (pic. 4.32) engine oil cooler (cars with air conditioning).

18. Remove bolt 4 (cars without air conditioning).

19. Turn away bolts and remove a pulley 2 pumps of the amplifier of a steering.

20. Turn away bolts and remove the pump of the hydraulic booster of a steering from an arm together with the hoses connected to it.

Attention! Tie up the removed power steering pump with wire and place it in a location where it will not interfere with the removal and installation of the engine assembly.

21. Disconnect the air conditioning compressor wire connector and remove the compressor 8 from the bracket along with the connected hoses.

Attention! Tie the removed compressor with wire and place it in a place where it will not interfere with the removal and installation of the engine.

22. Disconnect the coolant temperature sensor connectors (on the temperature gauge) 17 and coolant temperature sensor 18.

23. Loosen the clamps and remove the heater hoses 16.

24. Loosen the clamps and remove the hoses 15 of the engine cooling system.

25. Turn away bolts 11 (cars with air conditioning).

26. Install a rolling hydraulic jack under the engine.

27. Remove from the engine the special tool used at removal of a transmission.

28. Fasten the engine to the yoke and hang it from a hoist or similar device.

29. Insert a block of wood between the jack foot and the engine sump and lift the engine slightly to unload the support, then remove the engine support bracket.

30. Check that all wires are disconnected from the engine (electrical connectors), hoses, etc., and then slowly lift the engine out of the engine compartment.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. When installing the engine, carefully check that the wires, hoses and wire connectors are not pinched.

2. Install a rolling hydraulic jack under the engine (by inserting a block of wood between the jack foot and the engine sump) and install the engine support bracket while adjusting the engine position with a jack.

3. While supporting the engine with a jack, disconnect the hoist.

4. Establish a reception pipe of system of release of the fulfilled gases.

5. Install the heatsink.

6. Install the gearbox.

7. Install the protective cover.

8. Adjust the injection pump control cable.

9. Fill in cooling liquid in the cooling system.

10. Adjust drive belt tension.

11. Install the air duct for the aftercooler.

12. Install intake hose and air filter.

13. Remove air from a fuel highway.

14. Install the hood.

15. With the engine installed in the vehicle's engine compartment, check the engine oil and coolant levels. Check that all previously removed wires and hoses are installed in their places.