Examination

1. Checking and adjusting valve clearances must be carried out on a cold engine.

2. Remove the cylinder head cover.

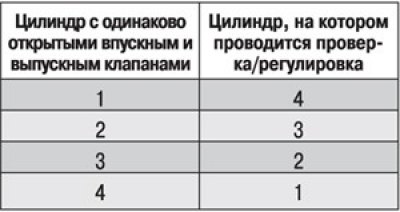

3. Check and adjust the clearances in the valve drive in the following sequence. Identify a cylinder with equally open intake and exhaust valves and check the valve clearances on a cylinder with equally closed intake and exhaust valves (see tab. 4.1).

Table 4.1. Cylinder number to be checked/adjusted based on cylinder number with inlet and outlet valves equally open

4. Turn the engine crankshaft at the crankshaft pulley bolt a quarter of a turn and take the next measurement.

5. Using a feeler blade, measure the valve actuator clearance. When measuring the gap, the feeler blade must move very tightly.

6. Rated clearance (engine cold):

- inlet valve 0.15–0.25 mm;

- exhaust valve 0.35–0.45 mm.

7. If the gap value does not fit within the specified limits, then adjust the gap by selecting shims of the required thickness by performing the following operations.

Adjustment

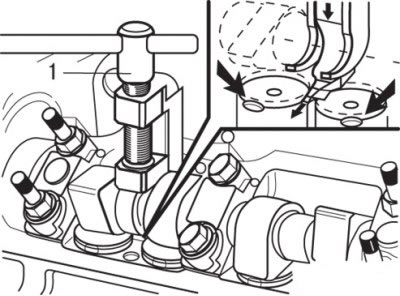

Pic. 4.3. Using a special tool (1) for adjusting the valve clearance

1. Unscrew the base of the special tool 1 (pic. 4.3) at a distance of 6 mm.

2. Move the slots of the pushers to the position shown in fig. 4.3.

3. Place the special tool with its base in the slot of the pushers and then push the special tool forward as far as possible.

4. Drown pushers.

Attention! When replacing shims, the piston must not be at TDC. Turn the crankshaft so that the piston is a little after TDC, otherwise, when the pushers are pressed, the valves may hit the pistons.

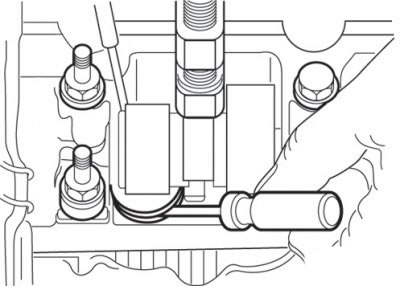

Pic. 4.4. Using a thin screwdriver to remove the shim

5. Use a thin screwdriver to remove the adjusting washer (pic. 4.4).

6. Select a shim of the required thickness that provides the nominal clearance.

7. Rated clearance (cold engine):

- inlet valve 0.20 mm;

- exhaust valve 0.40 mm.

Example.

If the measured gap is 0.25 mm, and the required gap should be 0.40 mm, then the old shim must be replaced with another one, the thickness of which is 0.15 mm less.

Attention! Measure the shim thickness with a micrometer. Always use new shims.

The thickness of the shims in the range from 3.25 to 4.25 mm is changed in increments of 0.05 mm, in the range from 4.30 to 4.50 mm in increments of 0.10 mm.

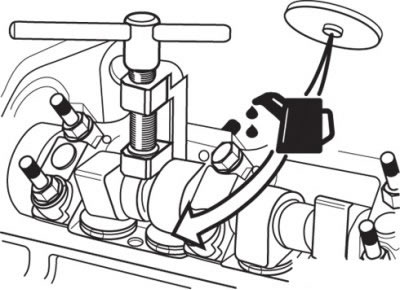

Pic. 4.5. Putting the shim in place (the protruding part should be directed towards the pusher)

8. Before installation, the adjusting washer must be lubricated with engine oil and reinstalled with the protruding part to the pusher (pic. 4.5).