Examination

1. Turn the crankshaft by the pulley bolt to set the piston of the 1st cylinder to the TDC position on the compression stroke.

2. Turn the crankshaft in the direction of its normal rotation an additional 13/4 turns.

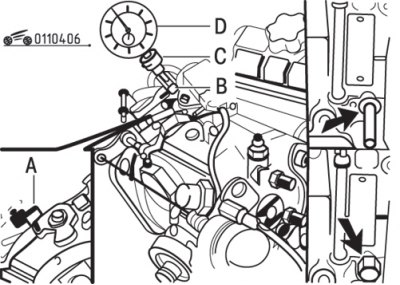

3. Remove plug A on the high pressure fuel pump (pic. 4.6)

Pic. 4.6. Installing a special tool (MV996030) to check the injection timing and location of the locking pin (arrow): A - cork; B - measuring rod; C - holder; D - dial indicator

4. Install special tool:

- install the guide sleeve in the high pressure fuel pump;

- insert measuring rod B, which is part of the special tool, into the pump guide;

- install and secure holder C;

- fit the D dial indicator head and make sure that the pump plunger is at least 0.2 mm recessed. Fix the indicator head and set the indicator to 0.

Attention! Measuring rod and guide sleeve are supplied and used as a set. You can not replace one of the parts with similar parts from another set.

5. Turn the crankshaft in the direction of its normal rotation until the indicator reads 5.00 mm.

6. Apply a slight force to the lock pin and at the same time continue to rotate the crankshaft until the lock pin enters the crankshaft hole.

7. Record the indicator reading.

8. This value should be 0.02mm (indicated on the pump control lever).

9. If the measured value does not match the specified value, it is necessary to adjust the fuel pump.

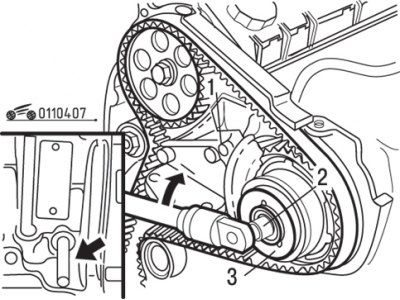

Pic. 4.7. Installing a special tool between the pump bracket and the pulley: 1 - special tool МВ996043; 2 - special tool МВ996036; 3 - pulley

10. Install special tool (pulley retainer) between pump bracket and pulley. Secure the tool with the bolt supplied with it (pic. 4.7).

11. Install the hex socket onto the threaded sleeve and nut assembly. loosen (clockwise rotation) threaded sleeve and nut assembly 1/8 turn. This will allow the pulley flange to be moved.

12. Remove the pulley retainer, lock pin, and indicator head.

Attention! The plunger is not spring loaded! Turning the crankshaft can break the indicator head.

13. Rotate the crankshaft an additional 1 3/4 turns, install the indicator head and verify that the plunger is 0.2 mm recessed. Check and adjust the fuel injection timing.

Adjustment

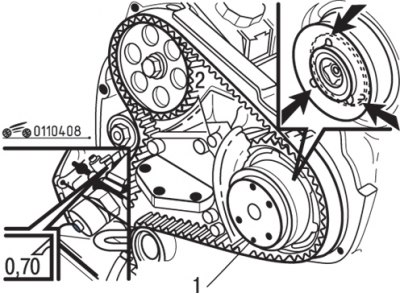

Pic. 4.8. Installation of a special tool in the three holes of the flange (arrows): 1 - special tool MB99G037

1. Install the special tool in the three holes of the flange (pic. 4.8).

2. Rotate the tool along with the flange until the jaws of the tool engage the three inner grooves of the pulley.

3. Turn the tool with the flange clockwise until the gaps in the pump are selected, then tighten it further so that the amount of movement is 0.5 mm less than recommended.

4. Now turn the tool, together with the flange, counterclockwise until the adjustment value indicated on the pump is reached with an accuracy of±0.02 mm.

5. Install the pulley retainer and secure it with the bolt supplied with the tool.

6. Turn the bracket with bolt 2 so that the bracket has no play.

Attention! The pump pulley must not move (the pointer of the indicator head is stationary).

7. Install special tool (hex socket head) on the threaded sleeve with nut assembly and tighten the assembly (counterclockwise rotation) nominal moment.

8. Remove special tool (pulley retainer), locking pin and indicator head.

9. Rotate the crankshaft 1 3/4 turns further, secure the indicator head and verify that the plunger has moved 0.2 mm.

10. Check up the moment of injection of fuel.

11. Remove the special tool along with the indicator head and measuring pin. Install the plug with a new O-ring.

12. Tighten the plug to 10 Nm.

13. Remove lock pin and install plug with new gasket.

14. Tighten the plug to 20 Nm.