Examination

1. Prepare the vehicle for inspection (warm up the engine to normal operating coolant temperature).

2. Connect the MUT-II to the diagnostic socket.

3. Check the engine idling speed, which should be (825±25) min-1.

4. If the measured value does not match the nominal value, adjust according to the following diagram.

Adjustment

5. Loosen the locknut and then, turning the idle speed adjustment screw, adjust it (the speed must correspond to the nominal value).

6. Tighten the idle speed adjustment screw locknut.

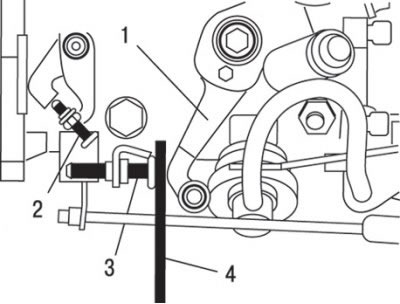

Pic. 4.9. Checking and adjusting the engine idle speed: 1 - control lever for injection pump; 2 – the screw of adjustment of frequency of rotation of idling; 3 - screw-limiter; 4 - flat probe

7. Install a 4 mm thick flat feeler gauge between the injection pump control lever and its travel stop screw (pic. 4.9).

8. Make sure that in this case the idle speed is (1250±100) min-1. If the rotational speed is outside the established limits, adjust it by turning the stroke limiter screw of the injection pump control lever.

9. Tighten the stop screw locknut.

10. Remove the feeler gauge.

11. Make sure the idle speed is within the nominal range. If the idle speed is out of range, repeat the adjustment operations.

12. Disconnect the MUT-II.