Removing

To remove the cylinder head gasket, perform the following steps in sequence.

1. Drain the coolant from the engine cooling system.

2. Remove the intake hose and air filter.

3. Remove a reception pipe of system of release of the fulfilled gases.

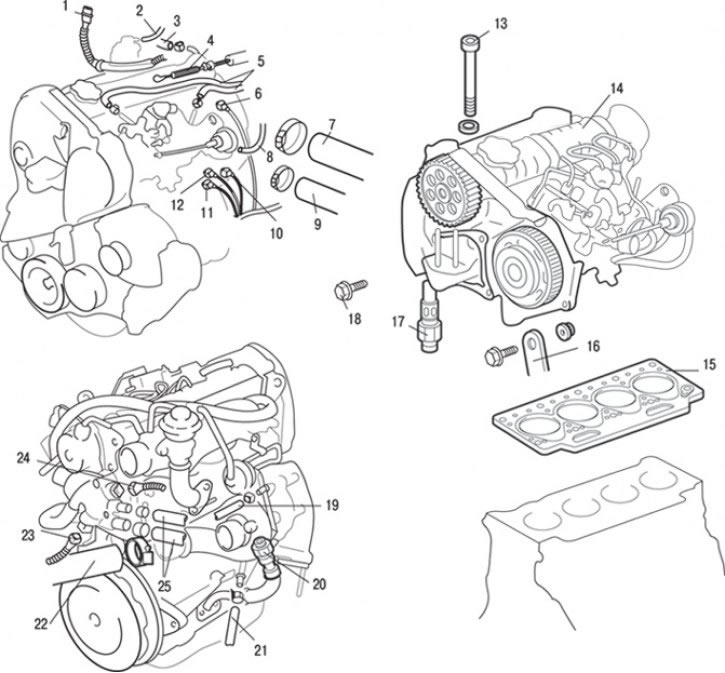

Pic. 4.26. Cylinder Head Gasket: 1 – a socket of the relay of glow plugs; 2 – connection of vacuum hoses; 3 – connection of a hose of the vacuum amplifier of brakes; 4 - connection of the injection pump control cable; 5 – connections of fuel hoses; 6 - connector for the injector needle lift sensor; 7 – connection of the top hose of a radiator; 8 – connection of vacuum hoses; 9 – connection of a hose of system of cooling; 10 - immobilizer connector; 11 – load lever sensor connector; 12 – socket of the electromagnetic valve of dispensing of fuel; 13 – a bolt of fastening of a head of the block of cylinders; 14 – a head of the block of cylinders in gathering; 15 - cylinder head gasket; 16 - connection of the turbocharger support bracket; 17 - connection of the oil pipe assembly, 30 Nm; 18 – a bolt of fastening of the bottom casing of a belt of a drive of the gas-distributing mechanism, 20 Nm; 19 – connections of hoses of system of cooling; 20 - connection of the oil return pipe, 25 Nm; 21 – connections of hoses of system of cooling; 22 - inlet hose connection A; 23 – a socket of the gauge of temperature of a cooling liquid (on the temperature gauge); 24 – a socket of the gauge of temperature of a cooling liquid; 25 - heater hose connections

4. Disconnect vacuum hoses 2 (pic. 4.26).

5. Loosen the clamp and disconnect the hose 3 of the vacuum brake booster.

6. Disconnect the connectors of the load lever sensor 11, the fuel metering solenoid valve 12, the immobilizer 10, the injector needle lift sensor 6 and the glow plug relay 1.

7. Disconnect a cable 4 managements TNVD.

8. Loosen the clamps and disconnect the fuel hoses 5.

9. Loosen the clamp and disconnect the upper hose 7 of the radiator.

10. Loosen the clamp and disconnect the hose 9 of the cooling system.

11. Disconnect the coolant temperature sensor connectors (on the temperature gauge) 23 and coolant temperature sensor 24.

12. Loosen the clamps and disconnect the heater hoses 25.

13. Loosen the clamps and disconnect the hoses 21 of the cooling system.

14. Turn away and disconnect tubes 20 of return of oil.

15. Loosen the clamp and disconnect the inlet hose A 22.

16. Turn away and disconnect an oil tube 17 in gathering.

17. Turn away a nut, take a bolt and separate a basic arm 16 of a turbocharger.

18. Remove the timing belt.

19. Turn away a bolt 18 fastenings of the bottom casing of a belt of a drive of the gas-distributing mechanism.

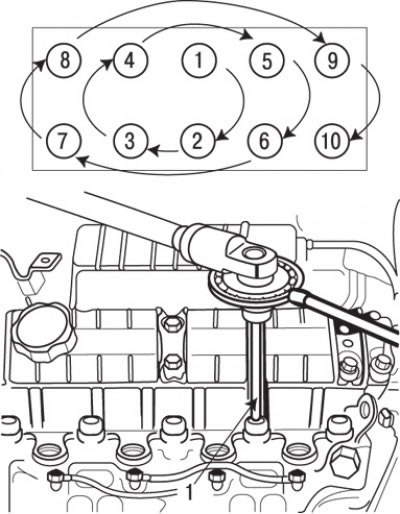

Pic. 4.27. The sequence of tightening the cylinder head bolts: 1 - a key for tightening bolts to the required angle (MV991614)

20. Turn out bolts of fastening of a head of the block of cylinders in 2 or 3 stages in sequence, the return specified on fig. 4.27, and then remove the cylinder head assembly.

21. Being careful, remove the head 14 (see fig. 4.26) cylinder block assembly.

22. Remove the gasket 15 of the cylinder head.

Preparing for installation

1. The mating surfaces of the head and cylinder block must be completely clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage. Check that carbon deposits do not get into the oil and water channels. This is especially important for the lubrication system, as deposits can block the oil supply to engine components. Clean channels if necessary.

2. Check the mating surfaces of the head and cylinder block for nicks, deep scratches and other damage. If the defects are small, they can be removed by machining. But in case of significant defects, the parts must be replaced.

3. Using a metal ruler and feeler gauge, check the flatness of the mating surfaces.

4. Clean the bolt holes in the block. Driving a bolt into an oil-filled hole may rupture the block due to hydraulic pressure.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Degrease adjacent gasket surfaces.

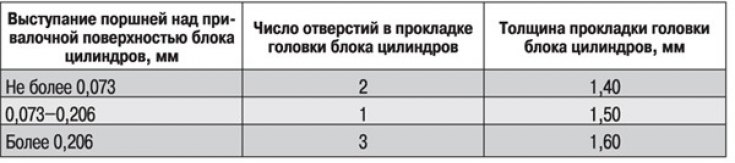

2. Select the cylinder head gasket of the required thickness in accordance with the amount of protrusion of the pistons above the mating surface of the cylinder block. The range of cylinder head gaskets is given in Table. 4.1. The thickness of the cylinder head gasket is determined by the number of holes on the edge of the gasket. Measure the amount of protrusion of the pistons above the mating surface of the cylinder block, calculate the average value. Then according to the table. 4.2 select the cylinder head gasket of the required thickness.

If it is necessary to replace the cylinder head gasket, determine the type of gasket and select the same one in shape and number of holes in it.

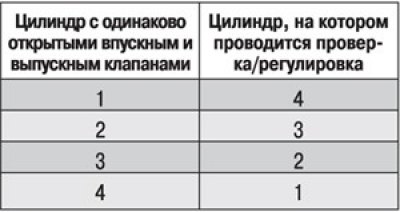

Table 4.1. Cylinder number to be checked/adjusted based on cylinder number with inlet and outlet valves equally open

Table 4.2. Head gasket thickness

Attention! When replacing a piston or connecting rod, always measure the amount of protrusion of the piston above the mating surface of the cylinder block, as this may change during such operations.

3. Turn the crankshaft so that the piston of the 1st cylinder has passed about a quarter of the stroke after TDC.

4. Lay a head of the block of cylinders so that adjusting pins of the block of cylinders have entered deepenings of a head of the block.

5. Before installing the bolts, check the length of the bolt shank (up to the head), which must be at least 120.5 mm. If at least one of the bolts is longer, all the cylinder head bolts must be replaced.

6. Install washers.

7. Before installation, it is necessary to lubricate the threaded parts of the bolts and the surfaces of the washers with a small amount of engine oil.

8. Tighten bolts of fastening of a head of the block of cylinders in 7 stages in the sequence shown in fig. 4.27.

Bolt tightening steps:

- 1st - tighten with a torque of 30 Nm;

- 2nd - tighten by an angle of 50°± 4°;

- 3rd - wait at least 3 minutes;

- 4th - completely loosen all bolts in reverse order;

- 5th - tighten with a torque of 25 Nm.

- 6th - tighten all the bolts at an angle of 213°± 2°.

- 7th - after warming up the engine, wait until it has completely cooled down, and then tighten the bolts by an angle of 120°± 2°.

9. Establish a reception pipe of system of release of the fulfilled gases.

10. Adjust the injection pump control cable.

11. Install intake hose and air filter.

12. Fill in coolant from the cooling system.

13. Remove air from the power system.