Front crankshaft oil seal

Removing

1. Remove the timing belt.

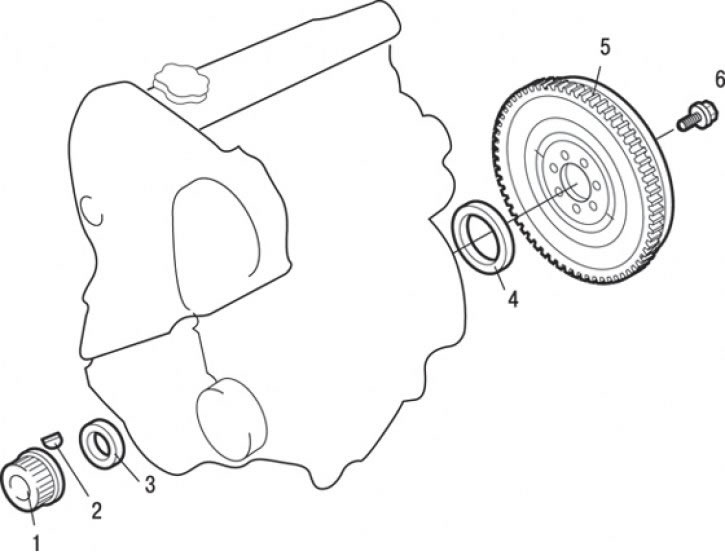

Pic. 5.10. Crankshaft seals: 1 - crankshaft pulley; 2 - key; 3 – a forward epiploon of a cranked shaft; 4 – a back epiploon of a cranked shaft; 5 - flywheel assembly; 6 - bolt, 53 Nm

2. Remove crankshaft pulley 1 and key 2 (pic. 5.10).

3. Drill two small holes in the front crankshaft oil seal located at diametrically opposite ends of the oil seal. Screw two self-tapping screws into the drilled holes in the stuffing box and use pliers to pull out the stuffing box 3 by the screw heads.

4. Clean the gland seat.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Lubricate the entire seal lip with a small amount of engine oil.

2. Install special tool MB996040 (guide) on the tip of the crankshaft.

3. Install the gland on the guide.

4. Using the special tool MB996040, install the oil seal in place.

5. Remove all traces of engine oil and install the crankshaft pulley.

Rear crankshaft oil seal

Removing

1. Remove the transmission assembly.

2. Remove the clutch cover and clutch disc.

3. Fix the flywheel or torque converter drive plate from turning by installing the special tool MB996015 on the flywheel ring gear, unscrew the bolts and remove the flywheel.

4. Drill two small holes in the crankshaft rear oil seal located at diametrically opposite ends of the oil seal. Insert two self-tapping screws into the drilled holes in the stuffing box and use pliers to pull the stuffing box out by the screw heads.

5. Clean the gland seat.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Lubricate the entire seal lip with a small amount of engine oil.

2. Install special tool (guide) on the shank of the crankshaft.

3. Install the gland on the guide.

4. Before installation, clean the mounting bolts and threaded holes in the crankshaft and flywheel from oil, sealant and other contaminants.

5. Apply 3M STUD Locking 4170 or equivalent to the threads of the mounting bolt holes.

6. Using the same special tool as during removal, fix the flywheel or torque converter drive plate and tighten the mounting bolts to 53 Nm.