Examination

1. Checking and adjusting valve clearances must be carried out on a cold engine.

2. Remove the cylinder head cover.

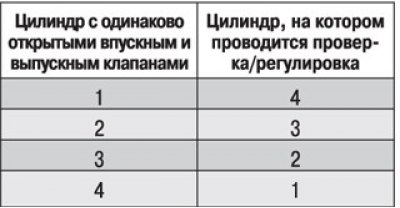

3. Identify a cylinder with equally open intake and exhaust valves and check the valve clearance on a cylinder with equally closed intake and exhaust valves (see table. 5.1).

Table 5.1. Cylinder number to be checked/adjusted based on cylinder number with inlet and outlet valves equally open

4. For the crankshaft pulley bolt, turn the engine crankshaft 1/4 turn in sequence and take the following measurement:

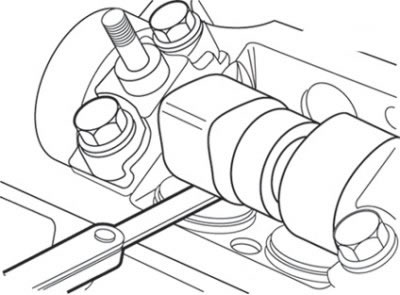

Pic. 5.1. Measuring the clearance in the valve drive with a feeler gauge

5. Use a feeler gauge to measure the clearance in the valve actuator (pic. 5.1). When measuring the gap, the feeler gauge must fit very tightly.

6. Rated value (engine cold):

- inlet valve 0.15–0.25 mm;

- exhaust valve 0.35–0.45 mm.

7. If the gap is not within specification, adjust it by following the steps below.

8. Re-measure gaps that are out of specification and record them.

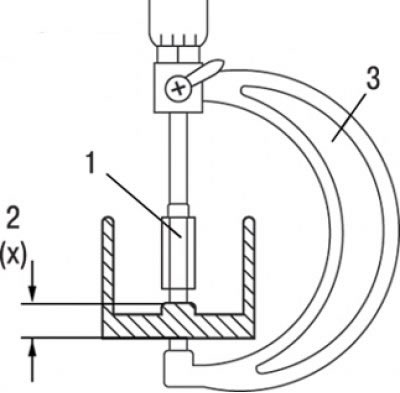

Pic. 5.2. Measuring the thickness of the pusher: 1 - adapter; 2 - thickness (X); 3 - micrometer

9. Using a micrometer, measure the thickness of the pusher X (pic. 5.2).

10. Select a plunger that is thick enough to provide the nominal clearance.

Pusher thickness to be adjusted = thickness of the measured pusher (X) + (measured value - standard value).

The thickness of the pushers is 7.550-8.150 mm, in increments of 0.025 mm.

Attention! Measure the thickness of the pusher with a micrometer.

Attention! Always install only new tappets.

11. Remove the camshaft and install the selected pusher.

12. Install the camshaft.

13. Turn the crankshaft in the direction of its normal rotation and re-measure the valve clearances.