Disassembly

To disassemble, perform the following steps in sequence.

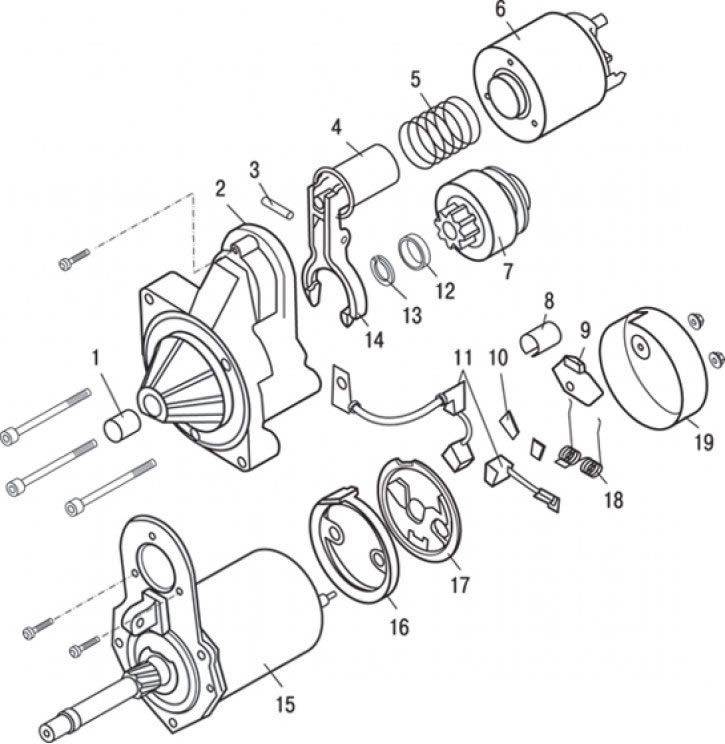

Pic. 9.26. Starter with reduction planetary gear: 1 - bearing sleeve; 2 - front cover; 3 - axis of the drive lever; 4 - core; 5 - spring; 6 - traction relay; 7 - freewheel; 8 - protective cover; 9 - rubber gasket; 10 - contact plates; 11 - brush; 12 - restrictive ring; 13 - retaining ring; 14 – drive lever; 15 - starter motor assembly; 16 - sealing insert; 17 - brush holder; 18 - brush spring; 19 - back cover

1. Loosen the nuts and remove the back cover 19 (pic. 9.26).

2. Remove the rubber seal 9.

3. Remove protective cover 8.

4. Remove brush spring 18.

5. Remove contact plates 10.

6. Remove brushes 11.

7. Remove brush holder 17 and sealing insert 16.

8. Unscrew the bolts and remove the front cover 2.

9. Remove bearing bush 1.

10. Turn away screws and remove the traction relay 6.

11. Remove spring 5.

12. Knock out the axis of the drive lever 3.

13. Remove core 4.

14. Remove drive lever 14.

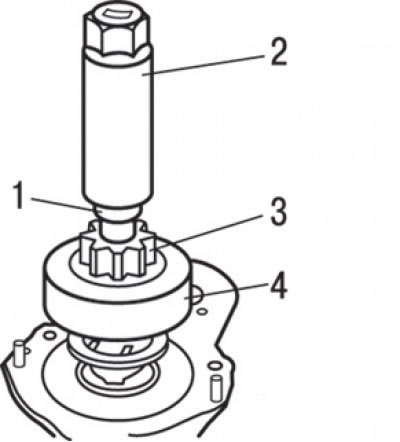

Pic. 9.27. Moving down the restrictive ring: 1 - restrictive ring; 2 - end head; 3 - drive gear; 4 - freewheel

15. Using a suitable socket, slide the stop ring down (pic. 9.27).

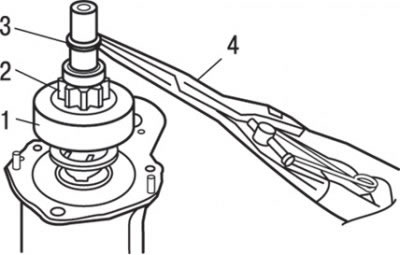

Pic. 9.28. Removing the restrictive ring: 1 - freewheel; 2 - drive gear; 3 - retaining ring; 4 - special pliers for removing retaining rings

16. Using special pliers, remove the retaining ring, then the restrictive ring and freewheel (pic. 9.28).

Cleaning the starter

Do not soak parts in cleaning solutions (solvents). Such washing of the pole assembly with the stator and/or armature windings will damage the insulation of the windings. Wipe these parts with a cloth only.

Do not immerse freewheel assembly with drive gear in cleaning solution (solvent). The freewheel has grease lubricated at the factory, so the solvent will flush the grease out of the clutch.

The freewheel assembly with the drive gear can be wiped with a brush dampened with detergent solution and then wiped dry with a cloth.

Checking the freewheel

1. Hold the clutch housing with your hand and rotate the drive gear. The gear should rotate smoothly, without jamming, in one direction, and not rotate in the opposite direction. If the gear is sticking or turns in both directions, replace the freewheel assembly.

2. Check drive gear for excessive wear or nicks. If any are found, replace the freewheel assembly. If the drive gear is damaged, also check the flywheel/torque converter ring gear (automatic transmission) for scoring or excessive wear.

Checking the brushes

Check the length of the brush, which must be at least 11 mm.

Assembly

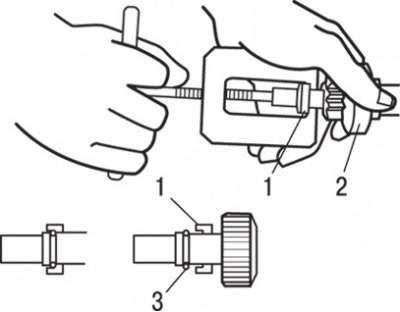

Pic. 9.29. Installation of restrictive and retaining rings: 1 - restrictive ring; 2 - freewheel; 3 - retaining ring

Assembly of the direct drive starter is carried out in the reverse order of disassembly, taking into account the following: using a suitable puller, fit the freewheel stop ring onto the retaining ring (pic. 9.29).