Gasoline Engine Generator 1600

Removing

To remove, perform the following steps in sequence.

1. Remove the A/C compressor drive belt and power steering pump.

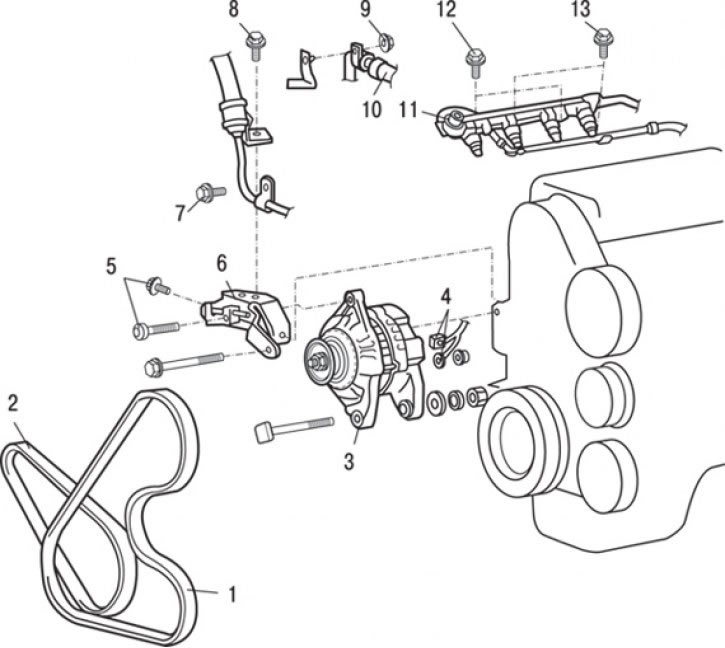

Pic. 9.4. 1.6L Gasoline Engine Generator: 1 – a belt of a drive of the compressor of the conditioner and the pump of the hydraulic booster of a steering; 2 - generator drive belt; 3 - generator; 4 - generator connector; 5 - bolt (20–25 Nm); 6 - adjusting bar of the generator; 7 - bolt (25 Nm); 8 – bolts of clamps of a tube of an oil pipeline (25 Nm); 9 - nut (14 Nm); 10 – connection of a hose of the conditioner; 11 - fuel rail and fuel return hose assembly (DOHC engine); 12 - bolt (10–13 Nm); 13 - bolt (10 Nm)

2. Loosen tension and remove alternator drive belt 2 (pic. 9.4).

3. Unscrew the bolts of the oil pipeline tube clamps 7, 8.

4. Turn away a nut of fastening of connection of a hose of the conditioner 10.

5. Remove the bolts and remove the fuel rail and fuel return hose assembly (engine with two overhead camshafts DOHC) 11.

Attention! Be especially careful and careful when removing the fuel rail - do not drop the nozzles on the floor.

6. Turn away bolts and remove an adjusting lath of the generator 6.

7. Disconnect the electrical connectors of the generator 4.

8. Turn away nuts, take a bolt of the lower fastening of the generator and remove the generator 3. Slightly move apart the details and elements interfering with removal of the generator.

Installation

Installation is carried out in the reverse order of removal.

Adjust the tension of the alternator drive belt.

Gasoline engine generator 1600 6V and 1800

Removing

To remove, perform the following steps in sequence.

1. On vehicles with air conditioning, install the ratchet wrench on the alternator tension bar.

2. Loosen the alternator mounting bolts.

3. Slowly loosen the alternator belt, then remove the belt.

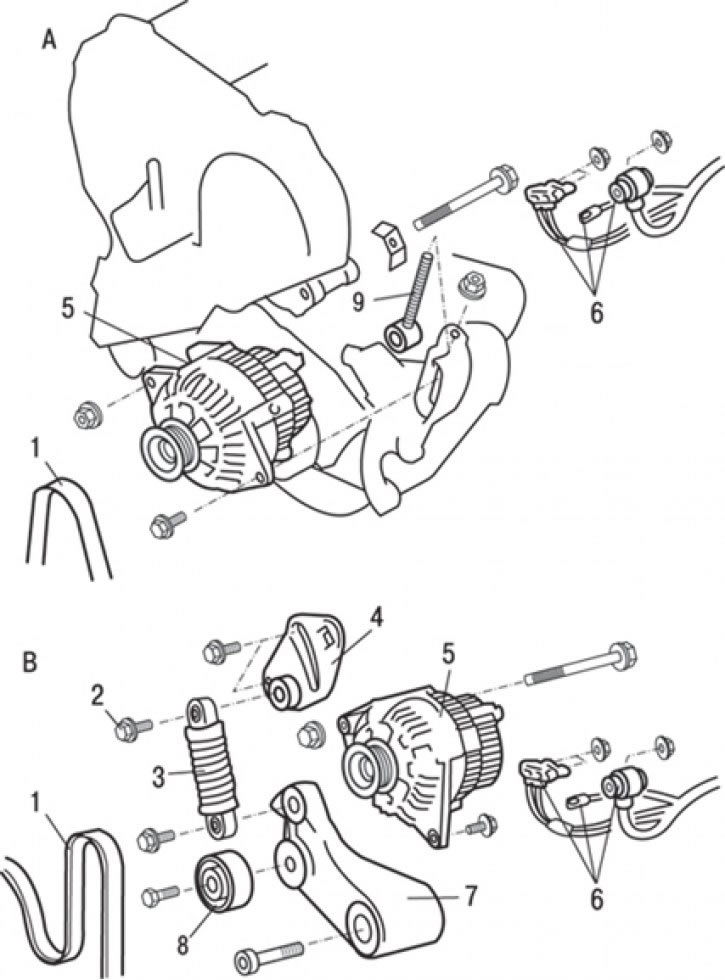

Pic. 9.5. Gasoline engine generator 1600 6V and 1800: A - cars without air conditioning; B - cars with air conditioning; 1 - generator drive belt; 2 - bolt; 3 - spring; 4 - tension bar of the generator; 5 - generator; 6 - connectors and connections of the generator; 7 - tensioner; 8 - pulley; 9 - bolt

4. Disconnect the electrical connectors of the generator 6 (pic. 9.5).

5. Turn away a bolt of fastening of a tension lath of the generator 2.

6. Unscrew the nut of the adjusting bolt 9.

7. Turn away bolts and remove a tension level of the generator 4.

8. Turn away bolts and remove a pulley 8.

9. Turn away bolts and remove a tensioner 7.

10. Turn away nuts, take a bolt of fastening of the generator and remove the generator 5.

Installation

Installation is carried out in the reverse order of removal.

1. On vehicles with air conditioning, fit the drive belt over the pulleys.

2. Place a ratchet wrench on the alternator tensioner and tension the belt, making sure that the belt is correctly positioned on the pulleys.

3. Tighten both screws.

4. Adjust the tension of the alternator drive belt.

F9Q Diesel Engine Generator

Removing

To remove, perform the following steps in sequence.

1. Remove the protective cover.

2. Remove the intercooler air hose.

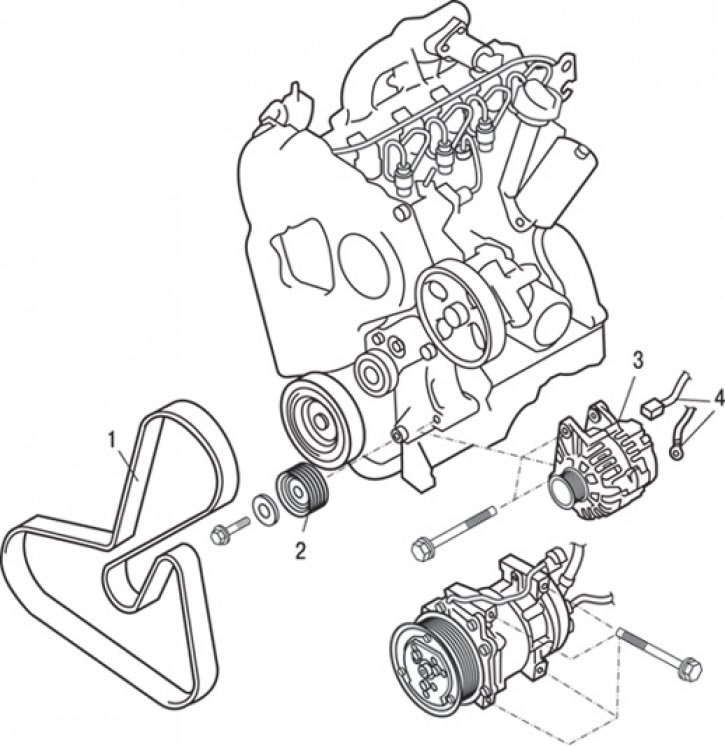

Pic. 9.6. F9Q Diesel Engine Generator: 1 - drive belt; 2 - idle guide pulley; 3 - generator; 4 - generator connector

3. Loosen the tension and remove the drive belt 1 (pic. 9.6).

4. Turn away a bolt and remove the idle directing pulley 2.

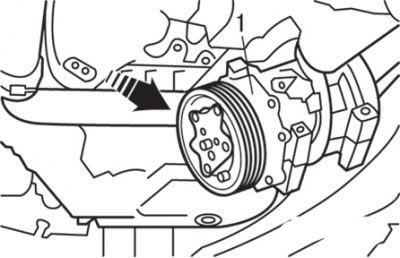

Pic. 9.7. Moving the A/C Compressor (1) when removing the generator

5. Turn away a bolt of fastening of the compressor of the conditioner. Reposition the A/C compressor so that there is enough space to remove the alternator to avoid damage (pic. 9.7).

6. Disconnect the electrical connectors of the generator 4 (see fig. 9.6).

7. Turn away nuts, take bolts of fastening of the generator and remove the generator 3.

Installation

Installation is carried out in the reverse order of removal.

1. Install the intercooler air hose.

2. Install the intercooler.

3. Install the protective cover.

Generator disassembly

To disassemble, perform the following steps in sequence.

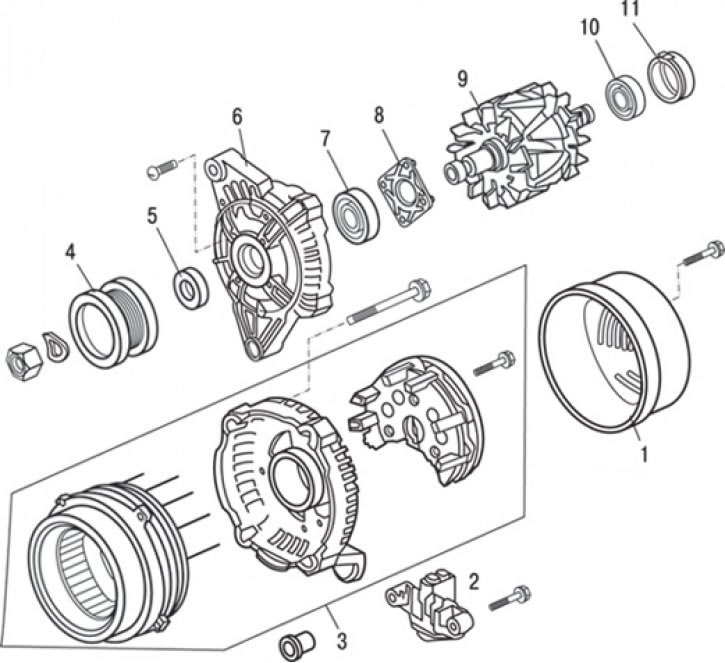

Pic. 9.8. Generator elements: 1 - rear protective cover of the generator; 2 - brush holder assembly; 3 - stator and rectifier unit assembled; 4 - generator pulley; 5 - remote washer; 6 - front cover; 7 - front bearing; 8 - bearing holder; 9 - rotor assembly; 10 - rear bearing; 11 - bearing cover

1. Loosen the screws and remove the rear protective cover of the generator 1 (pic. 9.8).

2. Loosen the screws and, being careful, remove the brush holder assembly 2.

3. Loosen the screws, remove the stator and rectifier assembly 3.

4. Remove bearing cover 11.

5. Secure the alternator front bracket in a soft jaw vise.

6. Use the special tool and socket wrench to secure the nut. Then fix the rotor shaft with a hexagon and loosen the nut. Loosen the nut and remove the pulley 4.

7. Remove spacer 5.

8. Remove the rotor assembly 9.

9. Remove rear bearing 10.

10. Remove the bearing holder 8.

11. Remove front bearing 7.

Assembly

Assembly is carried out in the reverse order of removal.

1. Secure the alternator front bracket in a soft jaw vise.

2. Use the special tool and socket wrench to fix the nut. Then fix the rotor shaft with a hexagon and tighten the nut.

Rotor check

1. Check for an open in the rotor winding. Check the circuit between the slip rings of the generator rotor.

2. If the resistance is too low (tends to 0), it means there is a short circuit. In the event of an open circuit in the rotor winding or a short circuit, replace the rotor assembly.

Resistance - about 2.6 ohms.

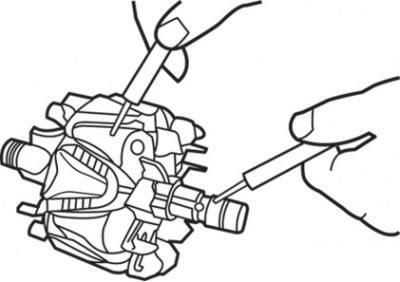

Pic. 9.9. Checking the electrical circuit between the slip ring and the generator core

3. Check that the rotor winding is not shorted to «mass» (pic. 9.9). Check the continuity between slip ring and core. If the circuit is closed (short circuit «mass»), replace the rotor assembly.

Stator check

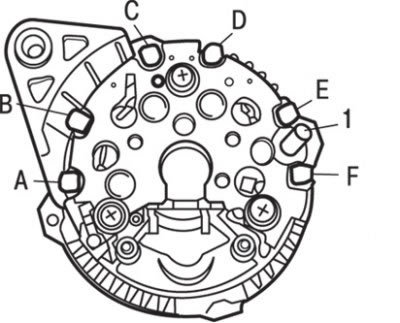

Pic. 9.10. Location of the stator windings: 1 - terminal «IN»

1. Check the stator winding. Check that there is no open circuit between the terminals («A» – «B»), («WITH» – «D») And («E» – «F») (pic. 9.10).

2. If the winding circuit is open (resistance tends to infinity), then replace the stator and rectifier assembly.

3. Check the absence of a short circuit in the stator winding for «mass». Make sure that the circuit between each stator winding terminal and the core is open.

4. If the circuit is closed (resistance tends to zero), replace the stator and rectifier assembly.

Checking the rectifier unit

1. Check the condition of the circuits between the terminal «IN» and stator winding leads («A», «WITH» And «E») (see fig. 9.10). A short circuit in both directions means a breakdown of the diode, so the stator and rectifier assembly must be replaced.

2. Check the condition of the circuits between the terminals of the stator windings («IN», «D», «F» And «weight»). A short circuit in both directions means a breakdown of the diode, so the stator and rectifier assembly must be replaced.

Brush replacement

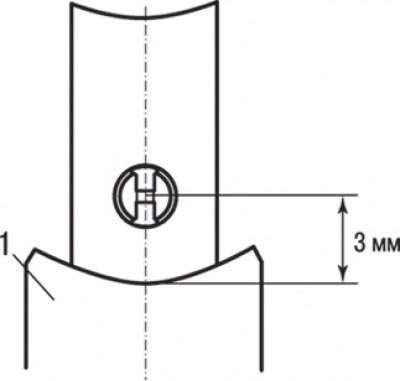

Pic. 9.11. Checking the wear of the generator brushes: 1 - brush holder

If the brush has worn to the center of the mark (3 mm from the middle of the brush holder), replace the brush holder assembly (pic. 9.11).