Removing

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the fuel pressure in the power supply system.

3. Remove the hood.

4. Drain the coolant from the engine cooling system.

5. Remove a transmission.

6. Remove the radiator.

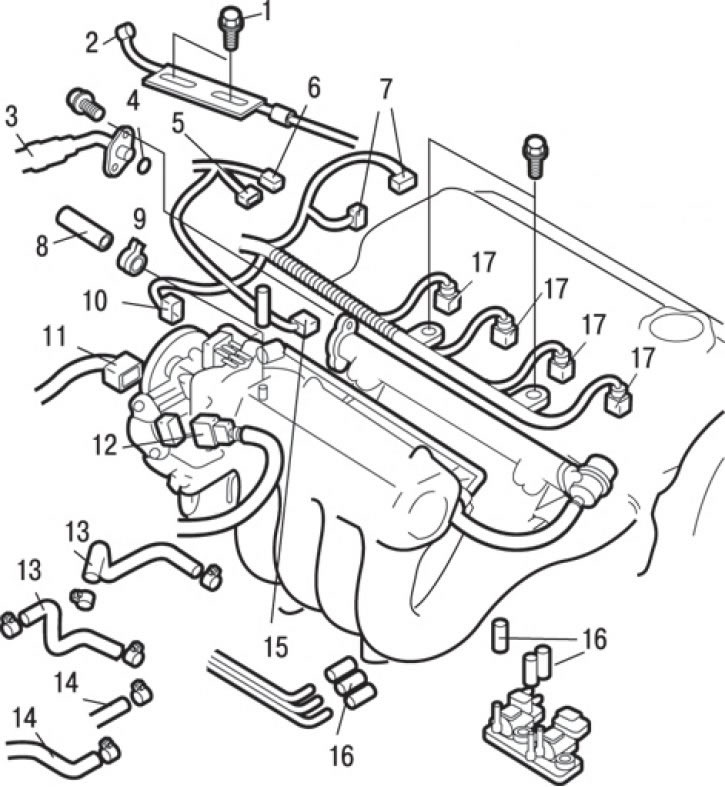

Pic. 3.62. Connecting connectors and hoses to the SOHC engine: 1 - bolt, 10 Nm; 2 – accelerator pedal cable connection; 3 – connection of a fuel hose of a high pressure; 4 - annular sealing gasket; 5 – a socket of the gauge of temperature of a cooling liquid; 6 – a socket of the gauge of temperature of a cooling liquid (pointer); 7 - connectors of the distributor; 8 – connection of a hose of return of fuel; 9 – connection of a vacuum hose of the amplifier of brakes; 10 – a socket of the gauge of position of a pedal of an accelerator (vehicles with TLC system); 11 – a socket of a regulator of frequency of rotation of idling; 12 - connector throttle position sensor (TPS); 13 – connection of coolant hoses; 14 – connection of heater hoses; 15 - knock sensor connector; 16 - connections of vacuum hoses; 17 - nozzle connector

7. Turn away bolts and disconnect a cable 2 (pic. 3.62) accelerator pedal.

8. Disconnect throttle position sensor connectors (TPS) 12, idle speed controller 11, accelerator pedal position sensor (vehicles with TLC system) 10, knock sensor 15, coolant temperature sensor 5, coolant temperature sensor (pointer) 6, distributor 7 and injectors 17.

9. Loosen the clamp and remove the fuel return hose 8.

10. Turn away bolts and disconnect a fuel hose 3 of a high pressure and an annular sealing lining 4.

11. Disconnect the brake booster vacuum hose 9.

12. Disconnect the vacuum hoses 16.

13. Loosen the clamps and disconnect the coolant hoses 13.

14. Loosen the clamps and disconnect the heater hoses 14.

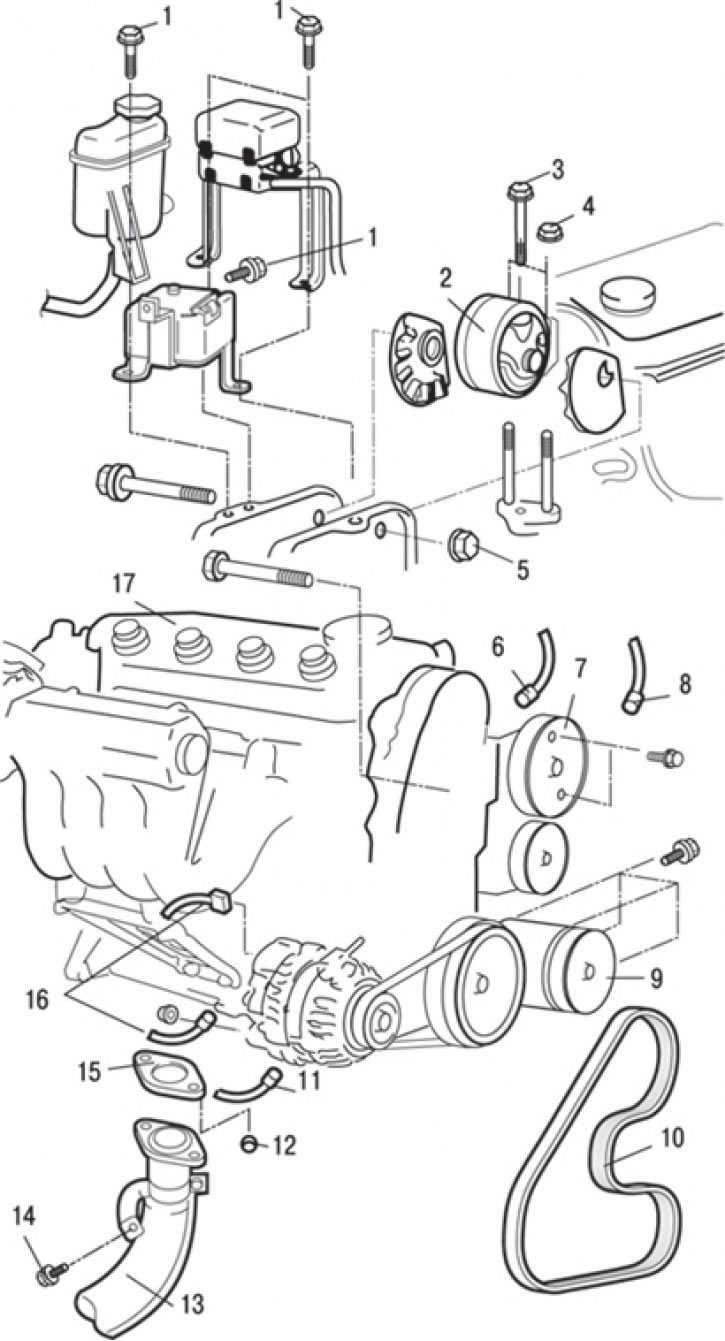

Pic. 3.63. SOHC Engine: 1 - bolts; 2 – an arm of a support of the engine; 3 - bolt, 62 Nm; 4 - nut, 62 Nm; 5* - nut, 118 Nm; 6 - sensor connector (switch) fluid pressure in the hydraulic system of the power steering; 7 – fastening of the pump of the hydraulic booster of a steering; 8 – a socket of the compressor of the conditioner; 9 – fastening of the compressor of the conditioner; 10 – a belt of a drive of the pump of the hydraulic booster of a steering and the conditioner compressor; 11 – a socket of the gauge-switch of pressure of oil; 12 - nut, 49 Nm; 13 – a reception pipe of system of release of the fulfilled gases; 14 - bolt, 50 Nm; 15 - gasket; 16 - generator connectors; 17 - engine assembly

15. Disconnect the sensor connectors (switch) 6 (pic. 3.63) fluid pressure in the hydraulic system of the power steering, air conditioner compressor 8, oil pressure switch 11 and generator 16.

16. Loosen the tension and remove the belt 10 for the drive of the power steering pump and the air conditioning compressor.

17. Turn away bolts and remove the pump of the hydraulic booster of a steering together with the hoses connected to it.

Attention! Removed power steering pump assembly with bracket and hoses tie with wire and place so that it does not interfere with the removal and installation of the engine assembly.

18. Disconnect the air conditioning compressor wire connector and remove the compressor from the bracket along with the connected hoses.

Attention! Tie the removed compressor with wire and place it in a place where it will not interfere with the removal and installation of the engine.

19. Turn away nuts, disconnect a reception pipe 13 of system of release of the fulfilled gases and remove a lining 15.

20. Turn out bolts 1.

21. Place a rolling hydraulic jack under the engine.

Attention! Mounting points marked with the icon (*), you must first pre-tighten, and after lowering the car to the ground (in unloaded state) tighten it completely.

22. Remove from the engine the special tool used at removal of a transmission.

23. Fasten the motor to the yoke and hang it from a hoist or similar device.

24. Insert a piece of wood between the jack foot and the engine sump and raise the engine slightly to unload the support; remove the engine mount bracket.

25. Check that all wires are disconnected from the engine (electrical connectors), hoses, etc., and then slowly lift the engine out of the engine compartment.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. When installing the engine, carefully check that the wires, hoses and wire connectors are not pinched.

2. Install a rolling hydraulic jack under the engine (by inserting a block of wood between the jack foot and the engine sump) and install the engine support bracket while adjusting the engine position with a jack.

3. While supporting the engine with a jack, disconnect the hoist.

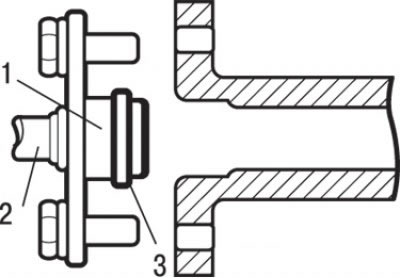

Pic. 3.44. High pressure fuel hose installation: 1 - place of lubrication with engine oil; 2 - high pressure fuel hose; 3 - ring gasket

4. When installing the high pressure fuel hose, lubricate the O-ring with a small amount of clean engine oil (see fig. 3.44).

Attention! Do not allow oil to enter the fuel rail.

5. Slightly turning the fuel hose flange to the right and left, carefully insert it into the fuel rail so as not to damage the O-ring. After installation, check that the hose turns smoothly in the fuel rail.

6. If the hose flange sticks when turning, the O-ring may be damaged. Detach the flange (complete with hose) from the fuel rail and inspect the gasket for damage, then reinsert it and check for smooth turning.

7. Tighten the mounting bolts.

8. Install the heatsink.

9. Install the gearbox.

10. Adjust the accelerator pedal cable.

11. Fill in cooling liquid in the cooling system.

12. Adjust drive belt tension.

13. Install the hood.