Removing

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the protective cover.

3. Remove the engine support bracket.

4. Remove the crankshaft pulley.

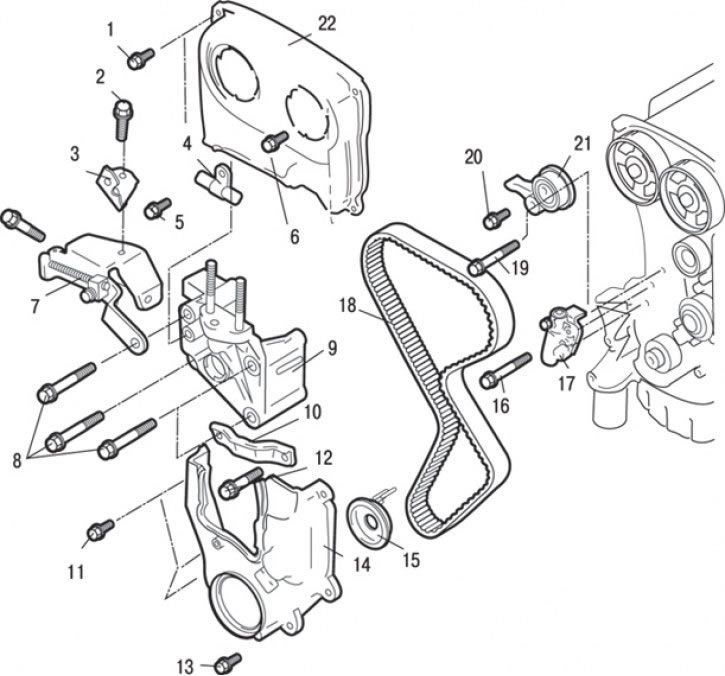

Pic. 3.53. DOHC timing belt: 1 - bolt, 9 Nm; 2 - bolt, 25 Nm; 3 – an arm of fastening of a hose of the hydraulic booster of a steering; 4 – a collar of fastening of a hose of the hydraulic booster of a steering; 5 - bolt, 25 Nm; 6 - bolt, 10–12 Nm; 7 - adjusting bar of the generator; 8 - bolts, 49 Nm; 9 – an arm of a support of the engine; 10 – an arm of fastening of the pump of the hydraulic booster of a steering; 11 - bolt, 9 Nm; 12 - bolt, 49 Nm; 13 - bolt, 9 Nm; 14 - the lower casing of the timing belt drive; 15 - flange; 16 - bolt, 12–15 Nm; 17 - automatic tensioner of the timing belt; 18 - timing belt drive; 19 - bolt, 44 Nm; 20 - bolt, 48 Nm; 21 - timing belt tensioner and bracket assembly; 22 - the upper casing of the timing belt drive

5. Turn away a bolt and remove an arm 3 (pic. 3.53) power steering hose fittings.

6. Turn away a bolt and remove a collar 4 fastenings of a hose of the hydraulic booster of a steering.

7. Turn away bolts and remove an adjusting level 7 of the generator.

8. Turn away bolts and remove the top casing 22 of a belt of a drive of the gas-distributing mechanism.

9. Turn away bolts and remove the bottom casing 14 of a belt of a drive of the gas-distributing mechanism.

10. Remove flange 15.

11. Turn away bolts and remove an arm 10 of fastening of the pump of the hydraulic booster of a steering.

12. Turn away bolts and remove an arm 9 support of the engine.

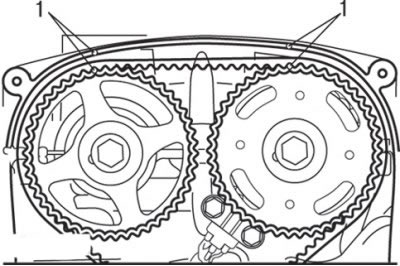

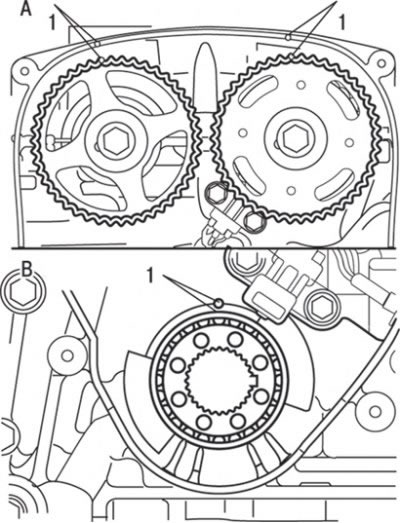

Pic. 3.54. Alignment marks (1) with pointers on DOHC engines

13. Rotate the crankshaft and align the alignment marks as shown in fig. 3.54.

Attention! Always turn the crankshaft clockwise only.

14. Loosen the central bolt of the tensioner pulley and remove the timing belt.

Attention! If the timing belt is reused, it must be chalked on the reverse (non-working) belt surface an arrow indicating the direction of rotation (right).

Installation

Installation is made in sequence, return to removal, taking into account the following.

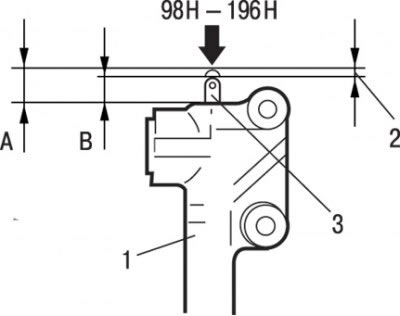

Pic. 3.55. Stem travel measurement: A - distance when the rod is in a free state, mm; B - distance when the stem is recessed, mm; 1 - tensioner; 2 - move (up to 1 mm); 3 - pusher rod

1. Apply a force of 98-196 N to the auto-tensioner rod, resting it against any hard surface (concrete, metal, etc.), and measure the movement of the rod, which should be no more than 1 mm (pic. 3.55).

2. If the travel is out of range, replace the auto tensioner.

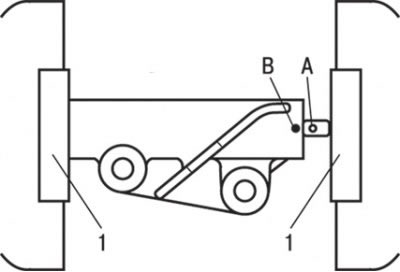

Pic. 3.56. Tensioner compression in a vise (1) to align holes A and B

3. Install the auto-tensioner in a vise as shown in fig. 3.56, and be careful not to damage (don't bend) push rod, compress the auto-tensioner until hole A aligns with hole B.

Attention! Perform this operation carefully and slowly so as not to damage the auto tensioner.

4. Insert the dowel pin into the aligned holes.

Attention! When replacing with a new tensioner, the dowel pin must already be inserted into the holes.

5. Install the automatic tensioner on the engine.

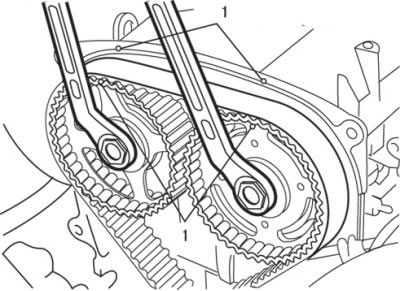

Pic. 3.57. Alignment of installation marks with pointers on DOHC engines: A - camshaft pulleys; B - crankshaft pulley; 1 - installation marks

6. Align the alignment marks on both camshaft pulleys and crankshaft with the corresponding fixed pointers (pic. 3.57).

7. Loosen the central tensioner pulley mounting bolt.

8. Turn the crankshaft pulley half a tooth counterclockwise.

9. Lay the drive belt on the exhaust camshaft pulley and secure the belt to this pulley with a clamp.

Pic. 3.58. Using two ring spanners to align the alignment marks (1)

10. Lay the timing belt on the intake camshaft pulley; using two spanners, align the match marks as shown in fig. 3.58.

11. Attach the drive belt to the other pulley with another clip.

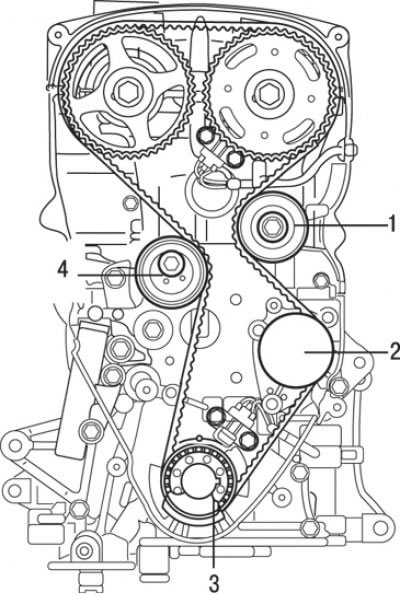

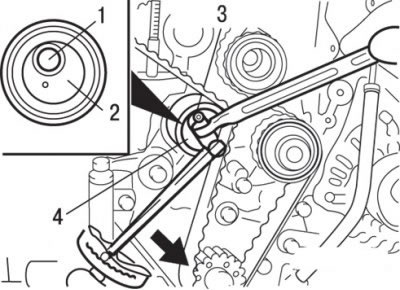

Pic. 3.59. The location of the timing belt on the engine pulleys: 1 - guide roller; 2 – a pulley of the water pump; 3 - crankshaft pulley; 4 - tensioner roller

12. Insert the timing belt in series onto the guide roller, water pump drive pulley, crankshaft pulley and tensioner pulley (pic. 3.59).

13. Remove clips.

Pic. 3.60. Direction of movement of the tensioner roller for pre-tensioning the belt

14. Move the tensioner roller in the direction of the arrow and tighten the mounting bolt (pic. 3.60).

15. Make sure all alignment marks are aligned.

16. Adjust the tension of the timing belt by turning the crankshaft 1/4 turn counterclockwise, and then return it to its original position by turning it clockwise and make sure that all the alignment marks are aligned.

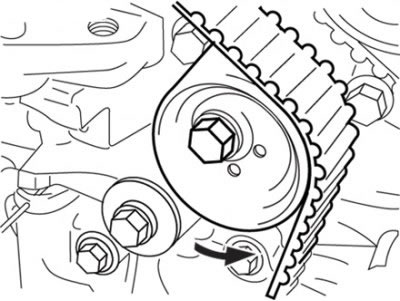

Pic. 3.61. Timing belt tension adjustment: 1 - fixing bolt; 2 - hole for the pin; 3 - special tool MD998767; 4 - tensioner roller

17. Loosen the fixing bolt of the tensioner roller and, using a special tool and a torque wrench, tension the timing belt, then tighten the fixing bolt to a torque of 2.5–4.0 N·m (pic. 3.61).

Attention! When tightening the fixing bolt, make sure that the tensioner roller is stationary at this time.

18. Remove the dowel pin (hex driver 2 mm) from the automatic tensioner. Make sure the pin is easy to remove.

19. Turn the crankshaft clockwise 2 turns, wait at least 5 minutes, make sure that the locating pin can also be easily removed or inserted into the auto-tensioner hole.

Attention! Even if the locating pin is not installed in the aligned holes, it is sufficient if the protrusion of the rod from the tensioner is within 3.8–4.5 mm.

20. If the protrusion does not correspond to the nominal value, repeat the belt tensioning operations. Make sure all alignment marks are aligned.

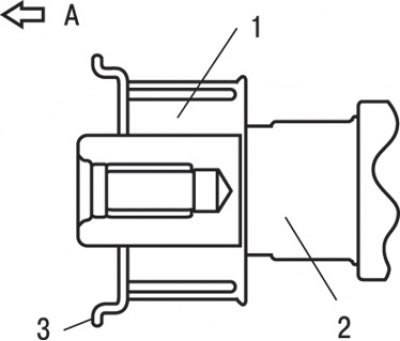

Pic. 3.52. Flange location: And – a forward part of the engine; 1 - crankshaft pulley; 2 - crankshaft; 3 - flange

21. Install the flange as shown in fig. 3.52.

22. Install the bottom guard.

23. Install the engine mount bracket.

24. Install the crankshaft pulley.