Removing

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the timing belt.

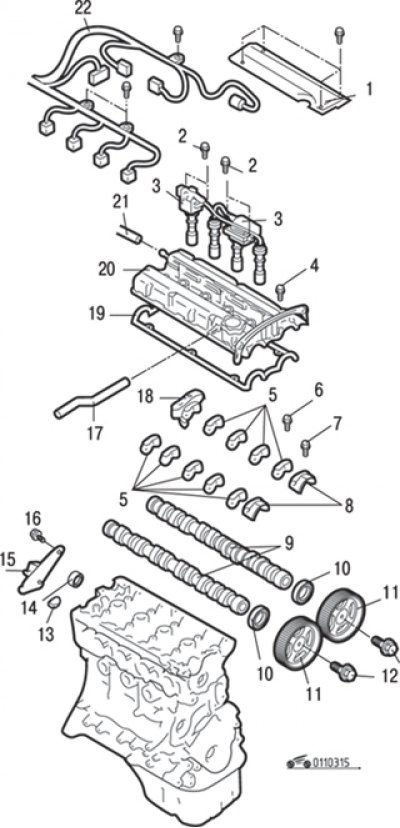

Pic. 3.15. DOHC engine camshafts and camshaft seals: 1 - central cover; 2 - bolts, 10 Nm; 3 - ignition coil assembly; 4 - bolt, 3.4 Nm; 5 – a cover of the bearing of a camshaft; 6 - bolt, 10–12 Nm; 7 - bolt, 21–25 Nm; 8 – forward covers of bearings of camshafts; 9 - camshafts; 10 – an epiploon of a camshaft; 11 - camshaft pulley; 12 - bolts, 88 Nm; 13 - semicircular plug; 14 - ring seal; 15 – the sensor of malfunction of system of ignition in gathering; 16 - bolt, 12–15 Nm; 17 - branch pipe of the forced crankcase ventilation system (PCV); 18 – a back cover of the bearing of a camshaft; 19 – a lining of a cover of a head of the block of cylinders; 20 – a cover of a head of the block of cylinders; 21 - connection of the crankcase ventilation hose; 22 – a plait of wires of a control system of the engine

3. Turn away bolts and remove the central cover 1 (pic. 3.15).

4. Turn away bolts and remove coils of ignition 3 in gathering with tips of high-voltage wires.

5. Disconnect the crankcase ventilation hose 21 and the branch pipe 17 of the forced crankcase ventilation system from the cylinder head cover (PCV).

6. Turn away bolts, disconnect electric sockets and remove plait of 22 wires of a control system of the engine.

7. Turn away a bolt and remove the gauge 15 of malfunction of system of ignition in gathering.

8. Turn away bolts and remove a cover 20 of a head of the block of cylinders together with a lining 19.

9. Remove semicircular plug 13.

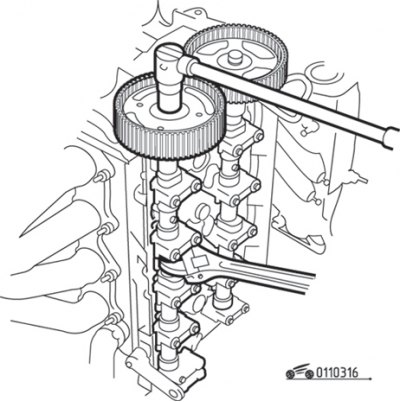

Pic. 3.16. Unscrewing the bolt securing the camshaft pulley

10. Holding the hex parts of the camshafts with a wrench, unscrew the bolts securing the camshaft pulleys and remove the pulleys (pic. 3.16).

Attention! To prevent damage to the camshaft pulley, do not hold it with a wrench.

11. Remove seals 10 (see fig. 3.15) camshafts.

12. Remove O-ring 14.

13. Turn away bolts and remove forward covers of 8 bearings of camshafts.

14. Turn away bolts and remove a back cover 18 of the bearing of a camshaft.

15. Evenly and gradually unscrew the bolts securing the camshaft covers, remove the covers 5 and camshafts 9.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Apply a coat of engine oil to the bearing journals and camshaft cams.

2. Lay camshafts in basic surfaces of a head of the block of cylinders.

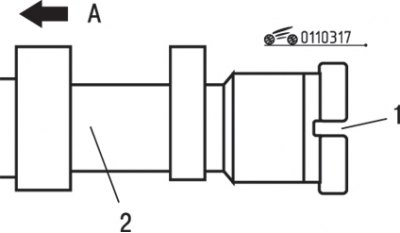

Pic. 3.17. The location of the groove on the exhaust camshaft: And – the party of a pulley of a camshaft; 1 - groove; 2 - exhaust camshaft

3. Do not mix up the camshafts. A groove is made on the rear end of the exhaust camshaft (pic. 3.17).

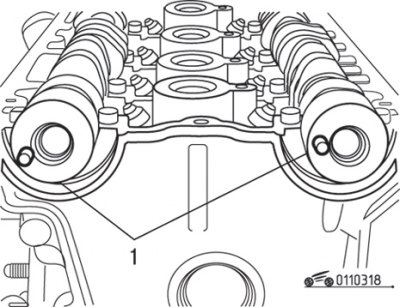

Pic. 3.18. Location of dowel pins (1) when installing camshafts

4. Position the camshaft locating pins as shown in fig. 3.18.

5. Correctly place recesses for an inhaling of bolts of covers of bearings of camshafts.

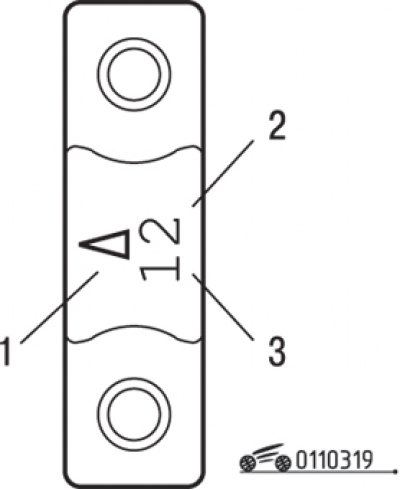

Pic. 3.19. Location of identification marks on the camshaft bearing cap: 1 - label «Before»; 2 – number of a cover of the bearing of a camshaft; 3 - identification symbol

6. Check the camshaft identification symbols and bearing cap numbers, install them, taking into account their correspondence and mark orientation «Before» (pic. 3.19).

The intake camshaft has an identification symbol «I», exhaust camshaft - symbol «E».

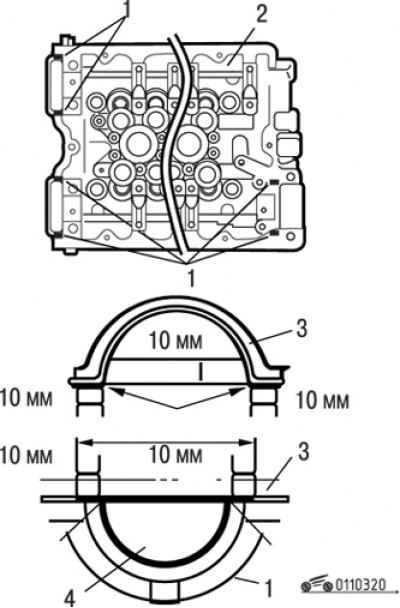

Pic. 3.20. Places for applying sealant to the cylinder head: 1 - places for applying sealant ZM ATD Part No. 8660; 2 – a head of the block of cylinders; 3 – a lining of a cover of a head of the block of cylinders; 4 - semicircular plug

7. Apply 3M ATD Part No. 8660 sealant or similar to the cylinder head locations shown in fig. 3.20.

8. After pre-tightening the camshaft bearing caps in 2–3 steps, finally tighten them to the nominal torque:

- 21–25 N·m - front and rear covers;

- 10–12 N·m - the remaining covers.

9. Make sure the rocker arms are correctly oriented with respect to the valve stems and hydraulic lifters.

10. Using a special tool or a tubular mandrel, install the O-ring.

11. Grease with engine oil a working edge of an epiploon of a camshaft.

12. When pressing in the camshaft oil seal, use a special tool.

13. To fix the pulley from turning, use a special tool (the same as when removing) and then tighten the bolts to 88 Nm.