2. Disconnect the 2-pin connector from the ignition distributor, connect a special tool to it (test lead harness MB 991348). All leads must be connected.

3. Connect a tachometer to the terminal «12» distributor connector.

Attention! Do not use MUT-II. If you connect it to the diagnostic socket, it will show the current ignition timing, and not the base one.

4. Install the stroboscope in accordance with its instruction manual.

5. Start the engine and let it idle.

6. Check up frequency of rotation of idling which has to correspond to nominal value.

7. Turn off the ignition.

8. Remove the waterproof plug from the brown base ignition timing connector.

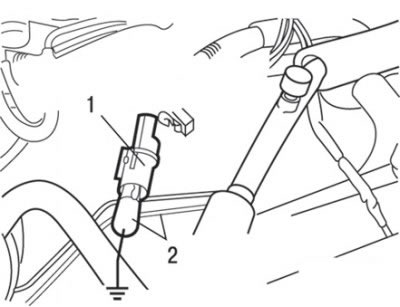

Pic. 3.5. Use of wire with connector type «crocodile» to connect the output of the connector with «weight» when adjusting the basic lead angle: 1 - brown connector for adjusting the basic ignition timing; 2 - wire with clamp type «crocodile»

9. With wire clamp type «crocodile» connect the lead of the basic lead adjustment connector to «weight» (pic. 3.5).

Attention! Connection with «weight» this connector puts the engine into basic ignition timing.

10. Start the engine and let it idle.

11. Check the value of the basic ignition timing, which should be within 5°± 2°before TDC.

12. If the value of the basic ignition timing does not match the nominal value, loosen the ignition distributor mounting bolt and adjust the ignition timing by turning the distributor housing.

13. After adjustment, tighten the ignition distributor mounting bolt to 24 Nm.

14. Stop the engine, disconnect the type connector «crocodile» wire from the ignition timing adjustment connector terminal and insert the waterproof plug into the connector.

15. Start the engine and check the ignition timing, which should be 10°before TDC.

Attention! Even during normal engine operation, the ignition timing changes within±7°.

As the altitude increases, the advance angle automatically exceeds the nominal value of 10°before TDC by approximately 5°.