Removing

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the fuel pressure in the power supply system.

3. Drain the coolant from the engine cooling system.

4. Remove the air intake hose.

5. Remove the timing belt.

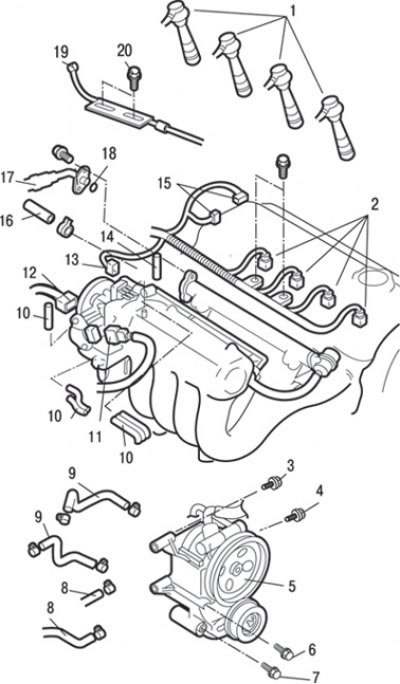

Pic. 3.38. Connecting connectors and hoses to the SOHC engine cylinder head: 1 - tips of high-voltage wires; 2 – injector connectors; 3 - bolt, 22 Nm; 4 - bolt, 44 Nm; 5 – an arm and knot of the pump of the hydraulic booster of a steering in gathering; 6 - bolt, 49 Nm; 7 - bolt, 44 Nm; 8 – connection of heater hoses; 9 - connection of hoses of the cooling system; 10 – connection of a vacuum hose; 11 - connector throttle position sensor; 12 – a socket of a servo drive of a regulator of frequency of rotation of idling; 13 – a socket of the gauge of position of a pedal of an accelerator (vehicles with TCL system); 14 – connection of a hose of the vacuum amplifier of brakes; 15 - connectors of the ignition distributor; 16 - connection of the fuel return hose; 17 - high pressure fuel hose connection; 18 - annular gasket; 19 - accelerator pedal cable; 20 - bolt, 10 Nm

6. Turn away bolts and disconnect an accelerator pedal cable 19 (pic. 3.38).

7. Pulling up, remove the lugs 1 of the high voltage wires.

8. Disconnect the connectors of the throttle position sensor 11, idle speed control servo 12, accelerator pedal position sensor (vehicles with TCL system) 13, ignition distributor 15 and injectors 2.

9. Loosen the clamp and disconnect the fuel return hose 16.

10. Unscrew the bolts, disconnect the high pressure fuel hose and remove the gasket 18.

11. Disconnect the vacuum brake booster hose 14.

12. Disconnect the vacuum hose 10.

13. Loosen the clamps and disconnect the cooling system hoses 9.

14. Loosen the clamps and disconnect the heater hoses 8.

15. Turn away bolts and remove an arm and knot 5 of the pump of the hydraulic booster of a steering in gathering together with the hoses connected to it.

16. Tie the removed power steering pump assembly with the bracket and hoses with wire and place it so that it does not interfere with the removal and installation of the cylinder head assembly.

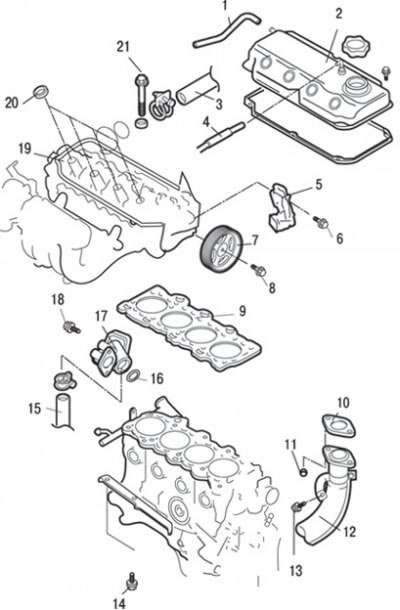

Pic. 3.39. SOHC Engine Cylinder Head Gasket: 1 - forced crankcase ventilation hose; 2 – a cover of a head of the block of cylinders; 3 – connection of a hose of a radiator; 4 - gas outlet hose (PCV); 5 - rear timing belt cover; 6 - bolt, 10–12 Nm; 7 - camshaft pulley; 8 - bolt, 88 Nm; 9 – laying of a head of the block of cylinders; 10 - gasket; 11 - bolt, 49 Nm; 12 – a reception pipe of system of release of the fulfilled gases; 13 - bolt, 50 Nm; 14 - bolt, 26–33 Nm; 15 – connection of a hose of a radiator; 16 - annular gasket; 17 - inlet pipe and thermostat in the housing as an assembly; 18 - bolt, 22–25 Nm; 19 – a head of the block of cylinders in gathering; 20 – a sealing ring of directing tubes of spark plugs; 21 – a bolt of fastening of a head of the block of cylinders, 78 Nm +0 Nm + 20 Nm + 90°+ 90°

17. Loosen the clamp and disconnect the radiator hose 3 (pic. 3.39).

18. Turn away bolts and remove an entrance branch pipe and the thermostat in the case in gathering 17 and a ring lining 16.

19. Disconnect the hose 1 forced ventilation of the crankcase and the hose 4 exhaust gases (PCV).

20. Turn away bolts and remove a cover 2 heads of the block of cylinders.

21. Using a special tool, fix the camshaft pulley from turning, unscrew the bolt and remove the camshaft pulley.

22. Remove the bolts and remove the rear cover 5 of the timing belt.

23. Turn away nuts and remove a reception pipe 12 and a lining 10 of system of release of the fulfilled gases.

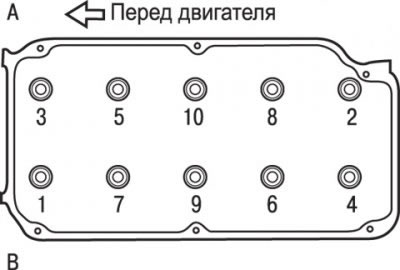

Pic. 3.40. The sequence of reversing the cylinder head bolts: And – the party of inlet valves; B - side of the exhaust valves

24. Turn out bolts 21 of fastening of a head of cylinders in 2 or 3 stages in the sequence resulted on fig. 3.40, and then remove the cylinder head assembly.

Attention! When removing the cylinder head bolts, be careful not to damage or deform the spark plug guide tubes as they are not replaceable.

25. Remove O-rings 20 (see fig. 3.39) spark plug guide tubes.

26. Being careful, remove a head 19 of the block of cylinders in gathering.

27. Remove the gasket 9 of the cylinder head.

Preparing for installation

1. The mating surfaces of the head and cylinder block must be completely clean. Use a hard plastic or wooden scraper to clean them. Be careful when cleaning as aluminum alloy is very easy to damage. Check that carbon deposits do not get into the channels of the lubrication and cooling systems. This is especially important for the lubrication system, since deposits can block the oil supply to engine components. Clean channels if necessary.

2. Check the mating surfaces of the head and cylinder block for nicks, deep scratches and other damage. Minor damage can be removed by machining. But in case of significant damage, the parts must be replaced.

3. Using a metal ruler and feeler gauge, check the flatness of the mating surfaces.

4. Clean the bolt holes in the cylinder block. Screwing a bolt into an oil-filled hole may rupture the block due to hydraulic pressure.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Degrease adjacent gasket surfaces.

2. Check up coincidence of all openings on a lining and a head of the block of cylinders.

3. Before installing the bolts, check the length of the bolt shank (up to the head), which should be no more than 96.4 mm. If this value is exceeded, the bolt must be replaced.

4. Bolt washer should be installed with the chamfered surface of the washer on top.

5. Before installation, it is necessary to lubricate the upper surface of the washer and the thread of the bolt with a small amount of engine oil.

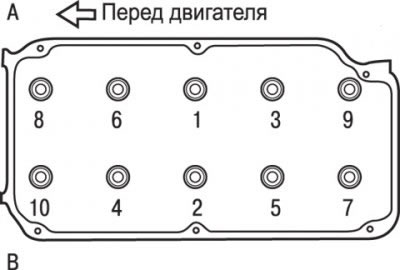

Pic. 3.41. The sequence of screwing in the cylinder head bolts: And – the party of inlet valves; B - side of the exhaust valves

6. Tighten bolts of fastening of a head of the block of cylinders in several stages in the sequence shown in fig. 3.41.

Bolt tightening steps:

- 1st - tighten with a torque of 78 Nm;

- 2nd - completely loosen all bolts in the reverse order shown in fig. 3.41;

- 3rd - tighten with a torque of 20 Nm;

- 4th - tighten the bolts by 90°. Apply paint marks on the bolt heads and cylinder head;

- 5th - tighten the bolts another 90°. The marks on the bolts and the cylinder head must be in line.

Attention! Always screw in the bolt at a strictly 90°angle. Otherwise, the cylinder head bolt may be loosened (connection will not be secure). If the bolt is turned more than 90°, loosen it completely and repeat all bolt tightening operations.

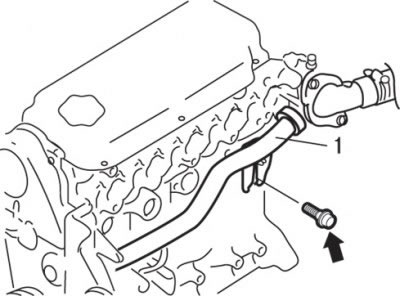

Pic. 3.42. Location of the inlet pipe bolt (1) cooling systems

7. At installation of an inlet pipe of system of cooling loosen a bolt of fastening of an inlet pipe, as is shown in fig. 3.42.

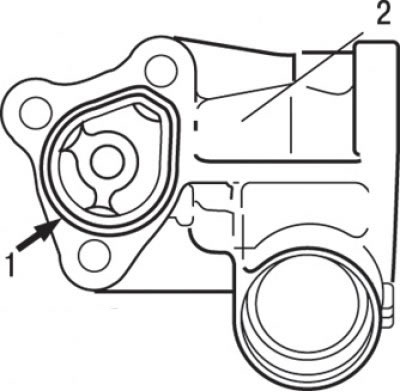

Pic. 3.43. Place of application (1) sealant in the form of a roller with a diameter of 3±0.5 mm Mitsubishi Genuine Part MD970389 or similar on the mating surface of the inlet pipe (2)

8. When installing the inlet and thermostat assembly, apply a bead of sealant to the mating surface of the inlet (pic. 3.43).

9. Moisten the O-ring of the cooling system supply pipe with water and insert the thermostat housing into the cooling system supply pipe.

10. Tighten the thermostat housing assembly bolts.

11. Tighten a bolt of fastening of an inlet pipe of system of cooling.

12. When installing the camshaft pulley, fix the pulley from turning with a special tool, as when removing it, and tighten the bolt to 88 Nm.

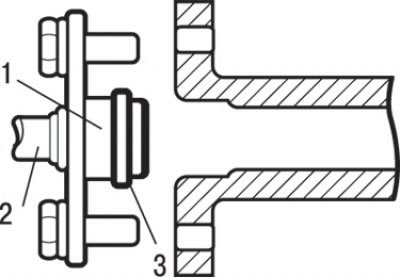

Pic. 3.44. High pressure fuel hose installation: 1 - place of lubrication with engine oil; 2 - high pressure fuel hose; 3 - ring gasket

13. When installing the high pressure fuel hose, lubricate the O-ring with a small amount of clean engine oil (pic. 3.44).

Attention! Do not allow oil to enter the fuel rail.

14. Slightly turning the fuel hose flange to the right and left, carefully insert it into the fuel rail to prevent damage to the O-ring. After installation, check that the hose turns smoothly in the fuel rail.

15. If the hose flange sticks when turning, the O-ring may be damaged. Detach the flange (complete with hose) from the fuel rail and inspect the gasket for damage, then reinsert it and check for smooth turning.

16. Tighten the mounting bolts.

17. Install the timing belt.

18. Install the air intake hose.

19. Fill in cooling liquid in the cooling system.

20. Adjust the accelerator pedal cable.