Attention! Sometimes after starting the engine or even during its operation, you can hear a characteristic persistent sound (clatter), which can be mistaken for the sound of the hydraulic compensator. In this case, you must do the following.

1. Check the engine oil level in the engine crankcase, top up or change the oil if necessary.

If the amount of oil is not enough, the oil pickup can entrain air, which mixes with the oil in the oil passages.

If there is too much oil, the counterweights agitate the oil in the sump, forming an oil-air emulsion.

Oil and air cannot easily separate in old oil, so the amount of air in the oil increases. If such a mixture enters the high pressure chamber of the hydraulic compensator, the air, when pressure is applied to the hydraulic compensator when the valve is opened, compresses the hydraulic compensator, as a result of which there is a sound when the valve is closed. This phenomenon also occurs when the clearances in the valve drive are too large.

The operation of the hydraulic lifters is restored when the air separates from the oil.

2. Start the engine and several times (about 10) accelerate it slowly. If the sound disappears, it means that the oil has been freed from air and the normal operation of the hydraulic lifters has been restored.

3. Gradually increase the engine speed from idle to about 3000 min-1 (within 30 s), and then gradually reduce the engine speed to idling speed (also within 30 s).

Attention! If the vehicle has been on a slope for a long time, oil may leak from the hydraulic lifter, and air will enter the high pressure chamber instead.

Attention! If the vehicle has been stationary for a long time, oil may leak from the oil passages. In this case, air can sometimes enter the high pressure chamber of the hydraulic lifters.

4. If, nevertheless, after performing the above operations, the sound does not disappear, check the condition of the hydraulic lifters:.

- turn off the engine;

- set the piston of the 1st cylinder to TDC on the compression stroke;

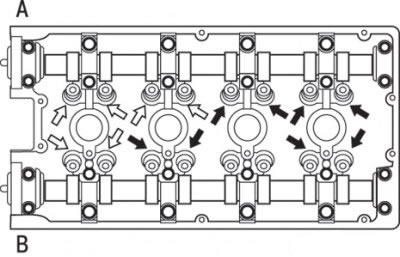

Pic. 3.7. When installing the piston of the 1st cylinder at TDC, check the operation of the hydraulic compensators indicated by white arrows, and after installing the piston of the 4th cylinder at TDC, check the operation of the hydraulic compensators indicated by black arrows: And – the party of inlet valves; B - side of the exhaust valves

- press the valve rocker in the area marked with white arrows (pic. 3.7), to check the position of the rocker arm;

- slowly rotate the crankshaft 360°clockwise;

- press the valve rocker in the area marked with black arrows (see fig. 3.7), to check the position of the rocker arm;

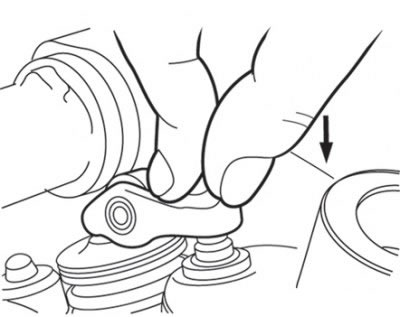

Pic. 3.8. Pushing the rocker arm when the cam profile is in the closed valve position

- if, when pressed, the rocker arm drops easily when the cam profile is in the closed valve position, as shown in fig. 3.8, the hydraulic compensator is defective and needs to be replaced. When replacing hydraulic lifters, remove air from them and check their condition again;

Attention! It is necessary to check the hydraulic compensator for leaks in order to accurately determine whether it is working or not.

- finally, if, when checking the rocker arms of the valves, they are not pressed through when they are pressed, the hydraulic compensator is working. In the same way, check all other hydraulic lifters.

Checking hydraulic valve clearance compensators

1. If, after starting the engine, as the engine warms up, extraneous noise appears and does not disappear (knock) from hydraulic lifters, carry out the following check:

- extraneous noise resulting from a malfunction of the hydraulic lifters appears immediately after starting the engine and changes in accordance with the engine speed. This noise is independent of the actual motor load. Therefore, if the noise does not occur immediately after starting the engine and does not change according to the engine speed or changes according to the engine load, then hydraulic lifters are not the cause of the noise;

- in the event of a malfunction of the hydraulic compensators, the noise almost never disappears, even when the engine is idling after it has warmed up. The only case where the noise can disappear is when the effects of insufficient care for the engine oil are eliminated, and the knock of the hydraulic lifters in this case is caused by contamination of the engine oil.

2. Start the engine.

3. Check that the noise appears immediately after starting the engine and changes according to the change in engine speed.

4. If the noise does not appear immediately after starting the engine or does not change when the engine speed changes, the malfunction is not caused by a malfunction of the hydraulic lifters - look for another cause of the malfunction. Moreover, if the noise does not change due to a change in engine speed, the cause of the malfunction is probably not in the engine (in these cases, the hydraulic lifters work normally.)

5. When the engine is idling, make sure that the noise level does not change when the engine load changes (for example, when switching the selector from the position «N» into position «D»). If the noise level fluctuates, the cause may be the collision of parts due to wear of the crankshaft bearings or connecting rod bearing shells (in such cases, the hydraulic lifters work normally).

6. After warming up the engine, let it idle and check for abnormal noise. If the noise has decreased or disappeared, it is possible that the knocking of the hydraulic lifters is caused by contamination of the engine oil. Clean hydraulic lifters.

7. Remove air from hydraulic lifters.

8. If the noise does not disappear even after removing the air, clean the hydraulic lifters.

Removal of air from hydraulic lifters

Attention! If the vehicle has been parked on a slope for a long period of time, the amount of oil in the hydraulic lifters will decrease, and when the engine is started, air may enter the over-piston chamber of the hydraulic lifter.

After a long parking of the car, the oil drains from the oil channel, the supply of oil to the hydraulic compensators takes a certain time, and air can enter the over-plunger cavity of the hydraulic compensator.

If any of the above situations occurs, extraneous noise can be eliminated by removing air from the hydraulic lifters.

1. Check the condition of the engine oil and top up or change it if necessary.

Attention! If the oil level is insufficient, air will be sucked in through the oil intake with a grid and enter the oil channel.

If the oil level is higher than required, the oil will be mixed with air by the crankshaft, resulting in a lot of air in it.

2. Oil and air cannot easily separate in the old oil, so the amount of air in the oil increases.

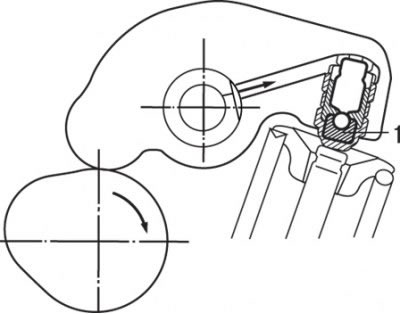

Pic. 3.9. Location of the supra-plunger cavity (1) in hydraulic compensator

3. If air mixed with oil due to one of the above reasons enters the over-plunger cavity of the hydraulic compensator, the air inside the over-plunger cavity will be compressed when the valve is opened and the hydraulic compensator will not be compressed, which will lead to extraneous noise when the valve is closed (pic. 3.9). This has the same effect as setting too much valve clearance by mistake. If the air from the oil disappears, the operation of the hydraulic lifters returns to normal.

4. To warm up the engine, let it idle for 1-3 minutes.

5. In conditions of no load on the engine for 15 seconds, increase the engine speed to 3000 min-1, then reduce the speed sharply to idling speed and let the engine idle for 15 seconds, then repeat the cycle and check if the extraneous noise disappears. During normal operation, the noise disappears after 10-30 cycles. If after 30 cycles or more the noise level has not changed, the cause of the noise is not air inside the hydraulic lifters.

6. After the noise disappears, repeat the cycle 5 more times.

7. Let the engine idle for 1-3 minutes and check that the noise has disappeared.

Replacement of hydraulic lifters

Attention! To prevent the valves from hitting the pistons when replacing the hydraulic lifters, it is necessary to rotate the crankshaft so that the pistons are below TDC. In some positions, the rocker arms are raised by the camshaft cams, so the hydraulic lifters cannot be removed. In these cases, the crankshaft must be in such a position that the rocker arms remain not raised.

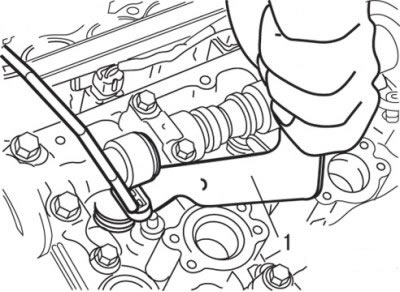

Pic. 3.10. Using the special tool MD998782 to move the valve down to remove the rocker arm of the roller tappet valve

8. Using a special tool, press the valve down and remove the valve rocker with a roller pusher (pic. 3.10).

9. Remove the hydraulic compensator from the cylinder head.

10. Install a new hydraulic compensator that has been bled of air.

11. With the same special tool, press the valve down and install the valve rocker with a roller pusher.

Attention! When installing the roller rocker arm of the valve, first install its shoulder on the upper part of the hydraulic compensator, then, pressing the valve down, insert the rest of the rocker arm onto the upper end of the valve stem.