Attention! A spring compressor must be used to disassemble the rear strut.

Disassembly

To disassemble the rear rack, perform the following operations.

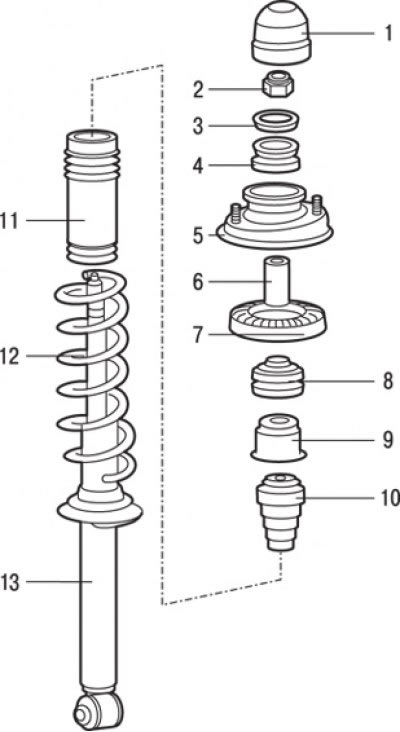

Pic. 16.17. Rear suspension strut: 1 - protective cap; 2 - self-locking nut (25 Nm); 3 - washer; 4 - top sleeve «IN»; 5 – the top support of a rack; 6 - sleeve; 7 - the upper cup of the spring; 8 - top sleeve «A»; 9 - shock absorber cup; 10 – compression stroke buffer; 11 - protective cover; 12 - spring; 13 - shock absorber assembly

1. Using the blade of a screwdriver as a lever, remove the protective cap 1 (pic. 16.17).

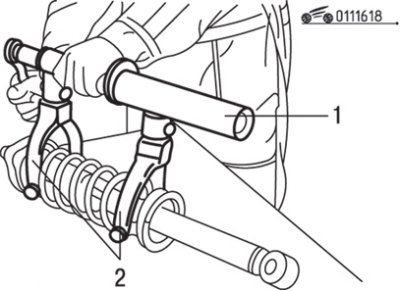

Pic. 16.18. Using Special Tools MB991239 (1) and MB991237 (2) for spring compression

2. Using special tool MB991239 1 (pic. 16.18) with grips MB991237, compress the spring so that it moves away from the top cup. When using a special device for spring compression, make sure that the coils of the spring are securely gripped, and the compression of the spring is carried out from opposite sides. The spring has a very high compression force, so use a reliable tool. Never tie the spring with wire.

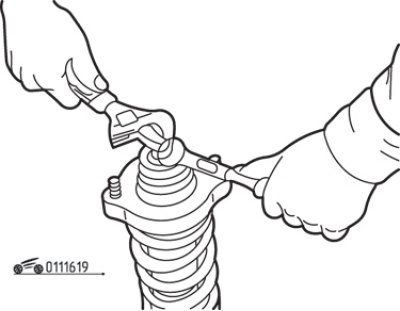

Pic. 16.19. Unscrewing the self-locking nut of the shock absorber rod

3. Lock the shock absorber rod from turning with a wrench and, using the second wrench, unscrew the self-locking nut of the shock absorber rod (pic. 16.19).

Attention! Do not use an impact wrench when loosening a self-locking nut.

4. Remove washer 3 (see fig. 16.17)

5. Remove the top sleeve «IN» 4.

6. Remove the top support 5 racks.

7. Remove the top cup 7 of the spring.

8. Remove the top sleeve «A» 8.

9. Remove sleeve 6.

10. Remove shock absorber cup 9.

11. Remove the protective cover 11.

12. Remove buffer 10 of the compression stroke.

13. Remove the spring 12 together with the spring compressor.

Examination

1. Check rubber parts for damage.

2. Check the rear suspension springs for wear, cracks or damage.

3. Check the shock absorber for leaks of damping fluid. Check the entire length of the shock absorber rod for pitting and the shock absorber housing for mechanical damage. Set the shock absorber to a vertical position and check its operation by moving the shock absorber rod through its full stroke. The shock absorber rod should move smoothly, with tangible resistance. If the shock absorber rod moves jerkily or there are mechanical damages, the shock absorber must be replaced.

Assembly

Assembly is carried out in the reverse order of removal, taking into account the following.

1. If a new spring is installed, compress it with a special tool (MV991237, MV991239) and install it on the shock absorber.

2. Align the bottom coil of the spring with the notch in the spring seat.

3. Install the compression stroke buffer, guard, then align the top coil of the spring with the notch in the top cup and install the cup.

4. Install sleeve, top sleeve «A» and top spring cup.

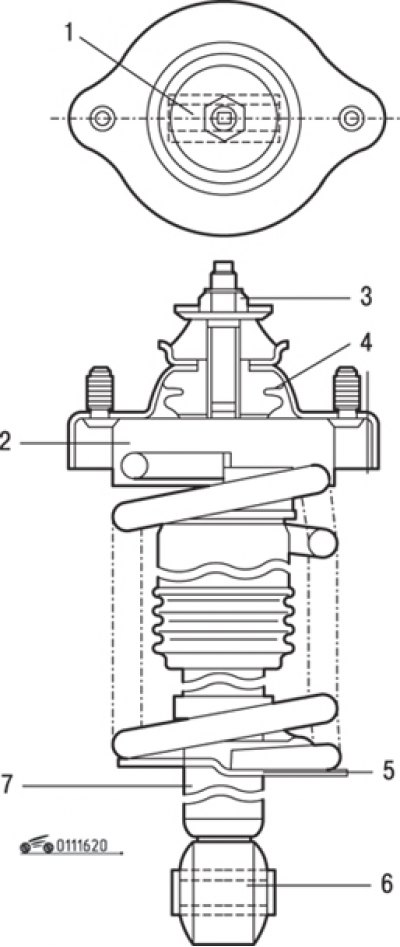

Pic. 16.20. The correct location of the upper support of the rack, while the axis of the inner tube of the lower bushing of the shock absorber must coincide with the line between the bolts of the upper support when viewed from above: 1 - inner tube of the lower sleeve; 2 – spring cup; 3 - self-locking nut; 4 – the top support of a rack; 5 – spring saddle; 6 - inner tube of the lower sleeve; 7 - shock absorber

5. Install the upper strut mount so that the axis of the inner tube of the lower shock absorber bushing coincides with the line between the upper mount mounting bolts when viewed from above (pic. 16.20).

6. Screw on and pre-tighten the self-locking nut.

7. Remove special tools for spring compression (MB991237 and MB991239) and finally tighten the self-locking nut to the specified torque.

Attention! Do not use an impact wrench when tightening the special tool bolt.