2. Before measurement, the elements and parts of the rear suspension and wheels must be brought into normal technical condition.

Convergence

If the toe-in value does not correspond to the nominal value, adjust it as follows:

1. Camber must be adjusted before toe adjustment.

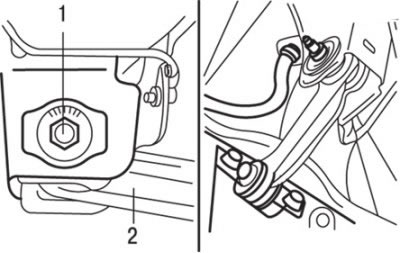

Pic. 16.4. Rear wheel alignment bolt location: 1 – a bolt of adjustment of a convergence; 2 - corrective lever

2. Carry out the adjustment of the convergence of the rear wheels by turning the adjusting bolt (mounting bolt on the inside of the suspension adjusting arm) (pic. 16.4).

Left side: Clockwise rotation of the bolt increases toe-in.

Right side: Clockwise rotation of the bolt reduces toe-in.

One scale division corresponds to a movement of approximately 2.6 mm, which is equivalent to a toe angle of one wheel of 0°16'.

Collapse

In case of deviation from the nominal value, adjust as follows:

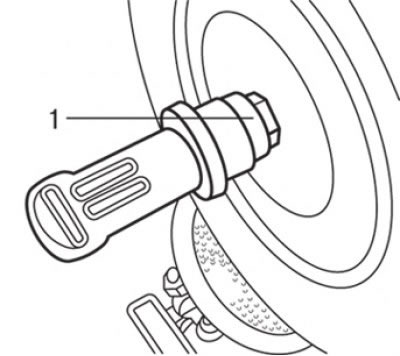

Pic. 16.5. Using the special tool MB991004 (1) for measuring camber on vehicles with aluminum rims

Attention! On vehicles with aluminum rims, measure the camber at each wheel using the MB991004 special tool (1, fig. 16.5), tightening it with a torque of 180 Nm. Do not load the rear wheel hub bearings with the full weight of the vehicle with the hub mounting nut loose.

1. Disconnect the adjusting arm from the trailing arm of the rear suspension.

2. Adjust the camber by turning the adjusting bolt (lower arm bolt to rear cross member) (see fig. 16.4).

Left wheel: Clockwise rotation increases camber.

Right wheel: Clockwise rotation reduces camber.

One division of the scale is approximately equal to 0°14'.

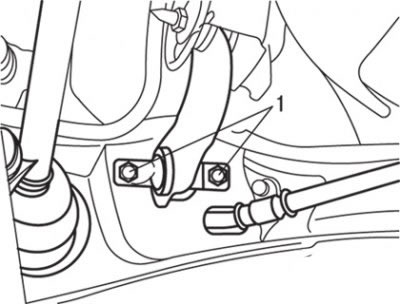

Pic. 16.6. Bolt location (1) fixing the adjusting lever to the trailing arm

3. Tighten the adjustment arm to trailing arm bolts to 34 Nm (pic. 16.6).

4. After adjusting the camber, be sure to adjust the toe-in of the rear wheels.