Removing

To remove the front wheel hub, perform the following steps in sequence.

1. Loosen the front wheel mounting bolts. Apply the parking brake, then raise the front of the vehicle and support it on stands. Remove the corresponding front wheel.

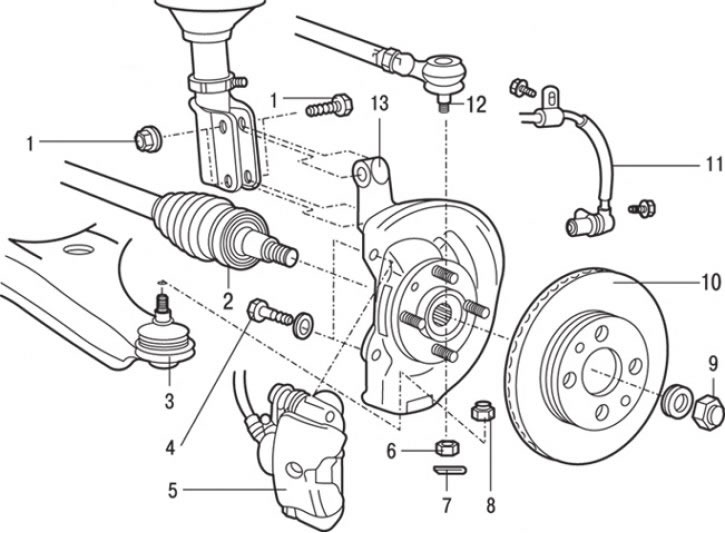

Pic. 15.3. Front wheel hub: 1 - bolt and nut for fastening the steering knuckle to the suspension strut (108–127 Nm); 2 - drive shaft; 3 - connection of the finger of the ball bearing of the lower arm with the steering knuckle; 4 - bolt (90–110 Nm); 5 - caliper assembly; 6 - nut (25 Nm); 7 - cotter pin; 8 - nut (67 Nm); 9 – a nut of fastening of a power shaft (216–255 Nm); 10 - brake disc; 11 - front wheel speed sensor (car with ABS); 12 – connection of a tip of steering draft; 13 - steering knuckle and hub

2. Remove sensor 11 (pic. 15.3) front wheel speed (car with ABS).

3. Turn away bolts and remove a support 5 of a forward brake from a rotary fist. Without disconnecting the brake hose from the caliper, use a soft wire to tie the caliper to the body. At the same time, do not stretch or twist the brake hose.

4. Remove the brake disc 10.

5. Using a special device to keep the hub from turning, unscrew the drive shaft mounting nut.

6. Remove the nut securing the lower arm ball joint trunnion to the front suspension strut. Using a puller, remove ball joint pin 3 from the front suspension strut.

7. Remove cotter pin 7, fixing the steering tip mounting nut.

8. Using a special tool, loosen the nut 6 fastening the tie rod end. The nut should be loosened, but not completely unscrewed. To prevent the puller from jumping off, you must first tie it with a rope or wire. Using a puller, press the ball joint out of the tie rod end and completely unscrew the nut.

9. Remove the outer end of the drive shaft 2 from the front wheel hub. Using soft wire, tie the end of the drive shaft to the body.

10. Turn away nuts and take bolts 1 fastenings of a rotary fist to a rack of a suspension bracket and remove a rotary fist with a nave.

Attention! On vehicles with ABS, special care must be taken with the protruding part of the wheel speed sensor tip to prevent it from hitting and damaging other parts.

Attention! On vehicles with ABS, when removing and installing the drive shaft, it is necessary to prevent damage to the rotor mounted on the outer race of the CV joint «Rzeppa» (R.J.) or «Bierfeld» (B.J.).

Examination

1. Check the hub for cracks and signs of excessive wear on the splines.

2. Check if the oil seal is damaged

3. Check up a rotary fist on absence of cracks.

4. Check up, whether the bearing of a nave is damaged.

Attention! If there is play between the steering knuckle and the bearing outer race or the hub and the bearing inner race, the bearing or damaged parts must be replaced.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

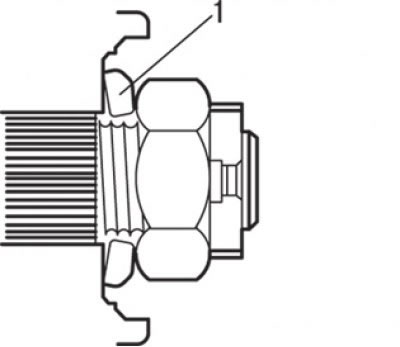

Pic. 15.4. Correct washer installation (1) under the drive shaft nut

1. Correctly install the washer under the drive shaft nut (pic. 15.4). Using a torque wrench, tighten the nut to the required torque, while holding the hub from turning with a special tool.

Attention! Before tightening the drive shaft nut, the front wheel hub bearing must not be under the force of the vehicle's gravity.

Disassembly

To disassemble the front wheel hub, perform the following operations.

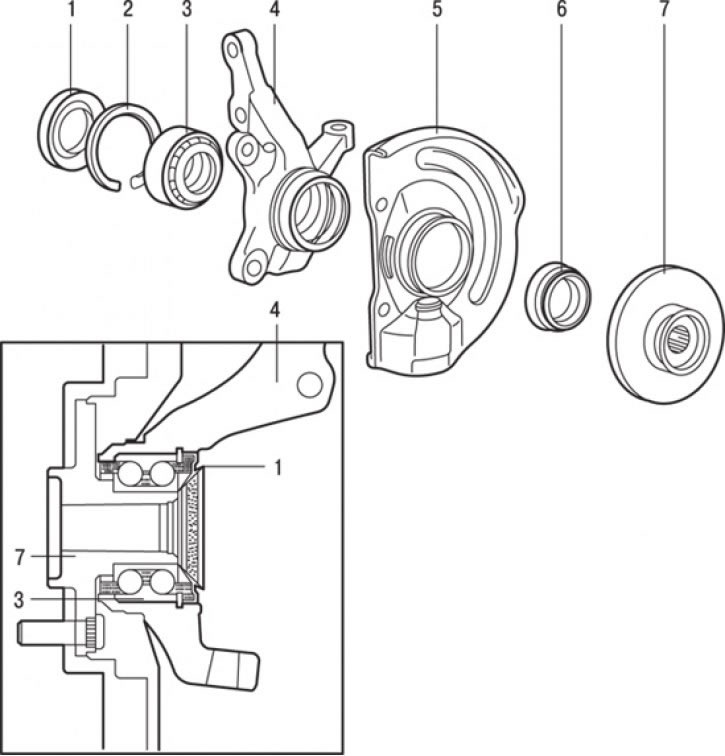

Pic. 15.5. Front wheel hub: 1 - inner stuffing box; 2 - retaining ring; 3 - hub bearing; 4 – rotary fist; 5 - mudguard; 6 - outer gland; 7 - hub

1. Remove inner seal 1 (pic. 15.5).

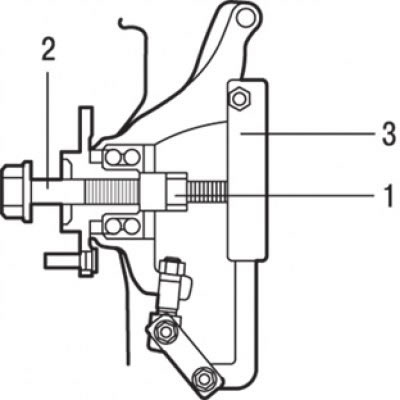

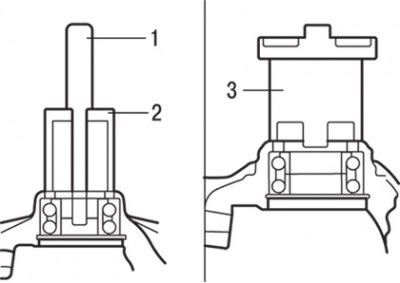

Pic. 15.6. Using Special Tools MB990998 (2), MV 991056 or MV 991355 (3) to remove the hub: 1 - nut

2. Using the special tool, remove the hub (pic. 15.6).

Attention! When removing the hub, always replace the hub bearing with a new one.

3. Unscrew two bolts and remove the mudguard 5 (see fig. 15.5).

4. Remove from a rotary fist a lock ring 2 fixing an external ring of the bearing.

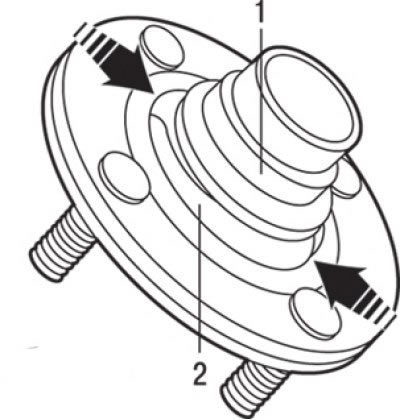

Pic. 15.7. Locations for breaking the outer seal: 1 - the inner ring of the bearing; 2 - outer gland

5. Remove the hub bearing. To capture the outer part of the inner ring using the jaws of a special puller, it is necessary to break the outer seal in two places (pic. 15.7).

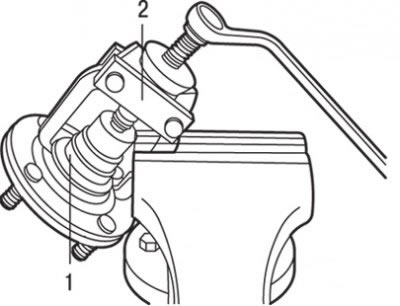

Pic. 15.8. Using a special puller MB990810 (2) to remove the inner ring from the hub (1) bearing

6. Using a special puller MB990810, remove the inner ring of the bearing from the hub (outer part) (pic. 15.8).

Attention! When removing the bearing inner race, hold the hub to prevent it from falling.

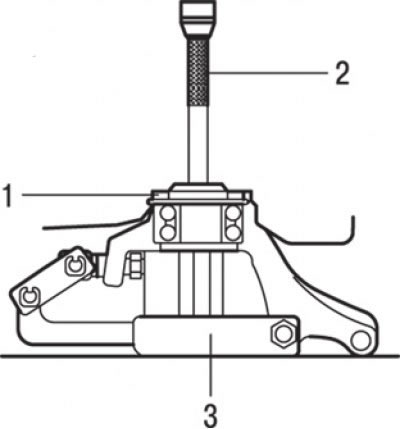

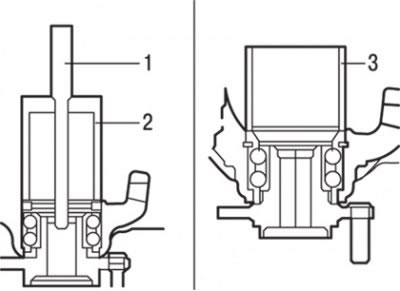

Pic. 15.9. Using a special bearing puller: 1 - the inner ring of the bearing; 2 - special puller МВ990938 and МВ990932; 3 - special tool МВ991056 or МВ991355

7. Install the outer part of the inner ring removed from the hub into the bearing and then, using a special puller, remove the bearing (pic. 15.9).

8. Remove the outer seal 6 (see fig. 15.5).

Examination

1. Check the condition of the mating surfaces of the front hub and brake disc for signs of wear and contamination.

2. Check up a condition of an internal surface of a rotary fist on absence of cracks and signs of wear.

3. Check the wheel bearing.

Assembly

Assembly is carried out in the reverse order of removal, taking into account the following.

Pic. 15.10. Using Special Tools MB990883 (1) and MB990890 (engine 1800) or MB991050 (engine1600) (2) for pressing the bearing into the steering knuckle

1. Install the hub bearing. Fill the bearing with multipurpose grease. Apply a light coat of grease to the mating surfaces of the steering knuckle and hub. Using special tools, press the bearing into the steering knuckle (pic. 15.10).

Attention! The pressing force is applied to the outer ring of the bearing.

2. Install retaining ring.

Pic. 15.11. Using the Special Mandrel MB990947 and MB990847 (1 and 2) for cars with engines 1800 and MB991387 (3) for vehicles 1600 to install the outer oil seal

3. Install the outer gland. Using a special mandrel MB990947 and MB990847 for cars with engines 1800 and MB991387 for cars 1600, install the oil seal (from the side of the hub) into the steering knuckle flush with the end surface of the steering knuckle (fig 15.11). Apply multipurpose grease to the seal lip, inside and end surfaces of the seal in contact with the hub.

4. Install the dirt guard.

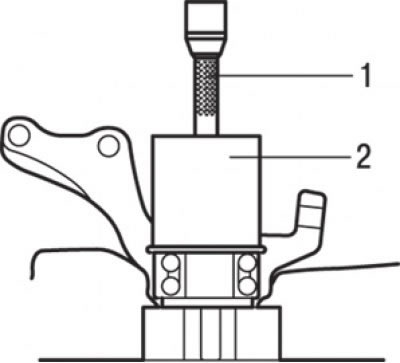

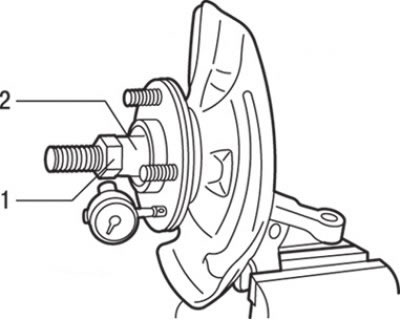

Pic. 15.12. Checking the axial clearance of the wheel bearing: 1 - nut (216–255 Nm); 2 - fixture МВ990998

5. Install the hub. Using a dial indicator, measure the axial clearance of the hub bearing, for which first fix the steering knuckle in a vise (pic. 15.12). The maximum allowable value is 0.05 mm. If, when tightening the nut with a special tool to a torque of 216–255 N·m, the value of the moment of rotation and the axial clearance of the hub bearing are not within the specified limits, then this is probably the result of incorrect installation of the bearing, hub and / or incorrect assembly of these parts with the steering knuckle. In this case, it is necessary to replace the bearing and assemble the assembly again. Tighten the nut to 216–255 Nm.

Pic. 15.13. Using tools MB990883 and MB990890 (1 and 2) for cars with engines 1800 and MB991389 (3) for cars 1600 for installing the inner oil seal in the steering knuckle

6. Install the inner gland. Apply multipurpose grease to the back of the inner seal. Using tools MB990883 and MB990890 for cars with 1800 engines and MB991389 for cars with 1600 engines, install the inner oil seal in the steering knuckle until it contacts the retaining ring (pic. 15.13). Apply a coat of grease to the seal lip.