Attention! A ball joint puller and spring compressor must be used to remove and disassemble the front suspension strut.

Disassembly

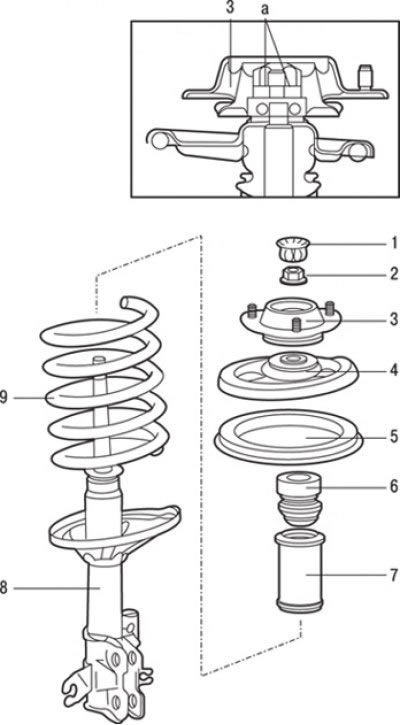

Pic. 15.25. Elements of the front suspension strut: a - the place of lubrication; 1 - dust cover; 2 - self-locking nut (78 Nm); 3 - damping support of the rack; 4 - the upper cup of the spring; 5 - spring pad, top; 6 – compression stroke buffer; 7 - protective cover; 8 – a forward rack in gathering; 9 - spring

1. Remove the dust cover 1 (pic. 15.25).

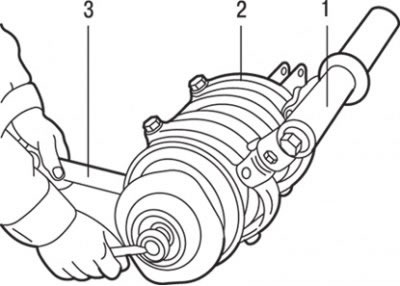

2. Fasten the front suspension strut and, using the special tool MB991237 with the grips MB991238, compress the spring so that it moves away from the upper cup. When using a special device for spring compression, make sure that the coils of the spring are securely gripped, and the compression of the spring is carried out from opposite sides. The spring has a very high compression force, so use only a reliable tool. Never tie the spring with wire.

Install special tools symmetrically and in such a way that their maximum length does not exceed the installation limits.

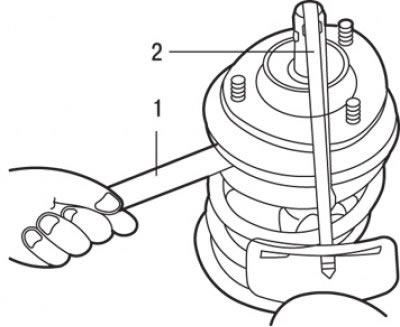

Pic. 15.26. Spring compression with tool MB991237 (1) with grips МВ991238 (2) and using a special key MB990278 or MB990775 (3) for loosening the self-locking nut of the front suspension strut

3. While holding the upper cup of the spring with a special wrench MB990278 or MB990775, loosen the self-locking nut (pic. 15.26).

Attention! Do not use an impact wrench when loosening a self-locking nut.

4. Remove damping support 3 (pic. 15.25) racks.

5. Remove the top cup 4 springs.

6. Remove the top pad 5 springs.

7. Remove the compression stroke buffer 6.

8. Remove protective cover 7.

9. Remove spring 9.

Examination

1. Check the shock absorber for shock absorber fluid leaks. Check the entire length of the damper rod for pitting. Check the shock absorber housing for mechanical damage. Set the shock absorber to a vertical position and check its operation by moving the shock absorber rod through its full stroke. The shock absorber rod should move smoothly, with tangible resistance. If the shock absorber rod moves jerkily or there are mechanical damages, the shock absorber must be replaced.

2. Check the bearing located in the front strut damping mount for wear or rust.

3. Check rubber parts for damage or deterioration.

4. Check the spring for deformation, wear or damage.

Rack Disposal

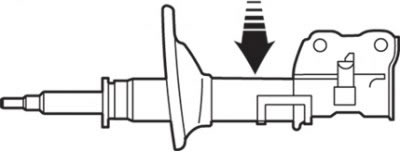

Pic. 15.27. Drilling location for a 3 mm hole for disposing of the front suspension strut

To dispose of a failed strut, lay it horizontally and extend the shock absorber rod until it stops. Then drill a hole with a diameter of about 3 mm at the location indicated by the arrow in fig. 15.27, and release the gas.

Attention! The gas itself is harmless, but when it escapes from the hole, chips left after drilling can fly out, so be sure to wear safety glasses.

Assembly

Assembly is carried out in the reverse order of disassembly, taking into account the following.

1. After compressing the helical spring with a special tool (MB 991237 and MB 991238) pre-tighten the self-locking nut.

Attention! Do not use an impact wrench when tightening the special tool bolt.

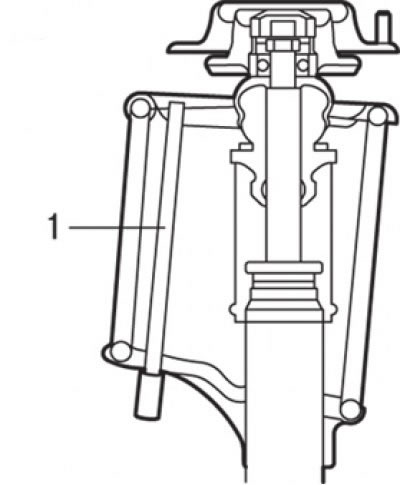

Pic. 15.28. Using a pipe section (1) for aligning the holes in the lower and upper support cups of the strut spring

2. Align the holes in the lower and upper support cups of the strut spring. This work can easily be done using a piece of pipe as shown in fig. 15.28.

3. Correctly align both ends of the spring with the grooves in the top and bottom cups, then loosen the spring compression tool.

Pic. 15.29. Using the special tool MB990278 or MB990775 (1) and torque wrench (2) for tightening a self-locking nut

4. Using the special tool MB990278 or MB990775 and a torque wrench, tighten the self-locking nut to the required torque (pic. 15.29).

Attention! Do not use an impact wrench.

5. Apply multipurpose grease to the front strut damper bearing.

Attention! When applying grease, be careful not to get grease on the damper mount rubbers.