Removing

Follow the steps below to remove the lower arm.

Use a ball joint remover to remove the lower arm ball joint pin from the steering knuckle.

Attention! To prevent the puller from jumping off, you must first tie it with a cord or wire.

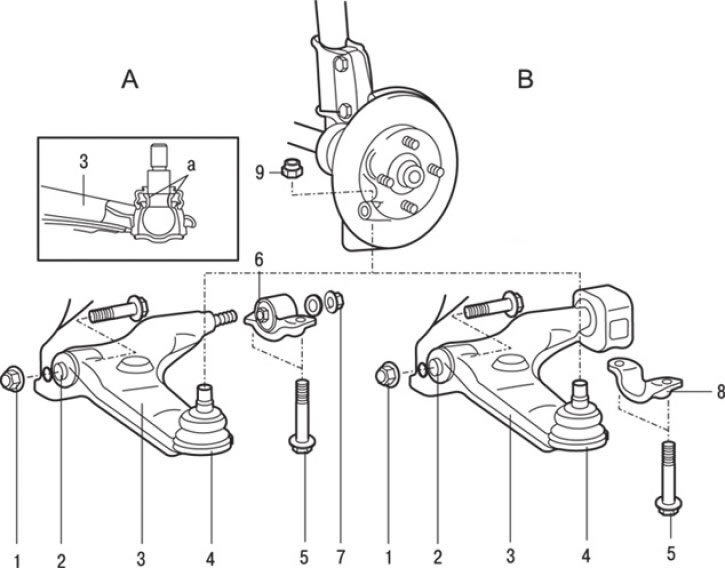

Pic. 15.30. Lower arm front suspension models from 1995 release: a - places for applying lubrication; A - cars with DOHC engines; B - cars with SOHC engines; 1* - nut (99–118 Nm); 2 - connection of the front bushing of the lower arm; 3 – the bottom lever in gathering; 4 - connection of the ball joint of the lower arm; 5 - bolt (88 Nm); 6 - rear bushing of the lower arm of cars with DOHC engines; 7* - nut (137 Nm); 8 - support bracket for cars with SOHC engines; 9 - nut

1. Loosen the ball joint pin nut, but do not remove it completely from the ball joint pin. Using a puller, remove the ball joint pin 4 (pic. 15.30) from the front suspension strut.

Note. Details marked with a sign (*) in fig. 15.30, must be pre-tightened, and the final tightening should be carried out after lowering the car in an unloaded state on the wheels.

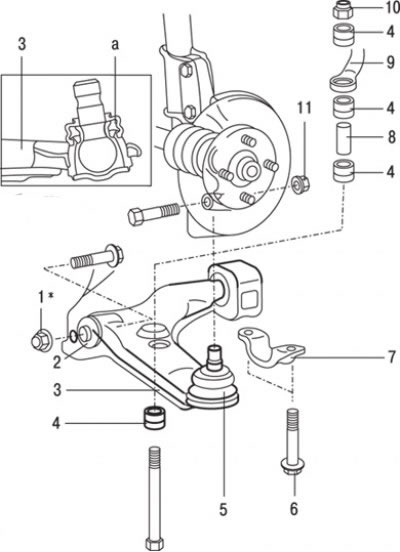

Pic. 15.31. Lower arm front suspension models from 1999 release: a - the place of lubrication; 1* - nut (88 Nm); 2 - connection of the front bushing of the lower arm; 3 – the bottom lever in gathering; 4 - rubber bushing of the anti-roll bar; 5 - connection of the ball joint of the lower arm; 6 - bolt (88 Nm); 7 - support bracket; 8 - sleeve; 9 - stabilizer bar; 10 - self-locking nut; 11 - nut (88 Nm)

3. On cars from 1999 on which the stabilizer is attached to the lower arm, unscrew the self-locking nut 10 (pic. 15.31) and remove rubber bushings 4 and sleeve 8.

4. On models with engines with two overhead camshafts (DOHC) unscrew the two bolts and disconnect the rear bushing 6 (see fig. 15.30) lower lever.

5. On models with single overhead camshaft engines (SOHC) unscrew the two bolts and disconnect the support bracket 8.

6. Remove the lower arm 3 as an assembly.

Attention! Details marked with a sign (*) in fig. 15.31, must be pre-tightened, and the final tightening should be carried out after lowering the car in an unloaded state on the wheels.

Examination

1. Check rubber bushings for wear or damage.

2. Check the lower arm for bending or cracks.

3. Check the support bracket for wear or damage.

4. Check ball joint protectors for cracks.

5. Check all bolts for bending and damage.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. On vehicles since 1999, tighten the self-locking nut so that the protrusion of the threaded part of the anti-roll bar mounting bolt corresponds to the nominal value of 22 mm.

2. Adjust the angles of the front wheels.