Removing

For removal of the working brake cylinder sequentially perform the following operations.

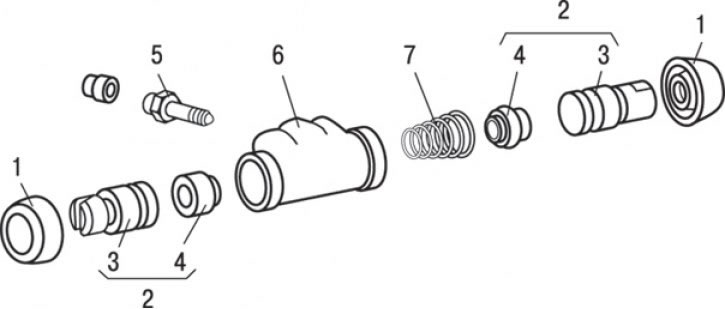

Pic. 14.34. Working brake cylinder: 1 - anther; 2 - piston assembly; 3 - piston; 4 - piston sealing rings; 5 - fitting for pumping (8 Nm); 6 - body of the working cylinder; 7 - spring

1. Remove boot 1 (pic. 14.34).

2. Remove pistons 2 as an assembly.

3. Remove sealing rings 4 from pistons.

4. Remove spring 7.

5. Turn out the union for prorolling 5.

Examination

Check the walls of the working cylinder and piston for damage or rust. At detection of deviations from norm replace the working brake cylinder in gathering.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

1. Before assembly, flush the piston and cylinder with alcohol or recommended brake fluid.

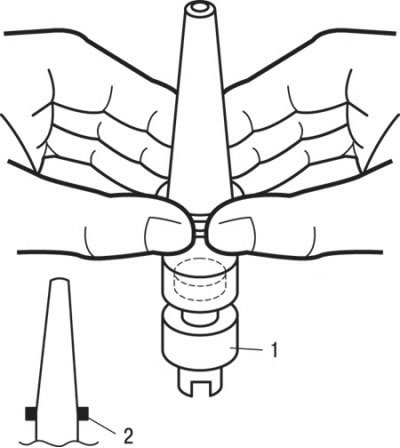

2. Lubricate the piston o-rings and special tool with brake fluid.

3. Slide the piston o-ring onto the special mandrel with the sharp edge facing up, then slide it over the mandrel into the piston groove.

Pic. 14.35. Mandrel use (1) to install the sealing ring (2) on the piston of the working brake cylinder

Attention! To avoid twisting or misaligning the piston o-ring during installation, lower it slowly and carefully, in one motion without stopping (pic. 14.35). The sharp edge of the piston sealing ring must be on top.