Slip minimum (0%), when the wheel rolls freely, and the maximum (100%), when the wheel is locked. Braking efficiency is greatest when the slip ratio is 15%, which allows you to maintain good stability and control of the car.

The role of the anti-lock braking system is to limit the pressure in the brake system so that the value of the slip coefficient is approximately equal to the recommended value.

The action of this system must be immediate and independent for each wheel. The system must respond immediately to every change in road surface and vehicle load.

To prevent blocking of the rear wheels on cars with an anti-lock braking system, a pressure regulator is installed in the drive of the brake mechanisms of the rear wheels, depending on the load on the rear axle of the car. With an increase in load, it provides the passage of fluid to the wheel cylinders of the rear brakes, which increases the pressure in their circuit and improves the efficiency of the rear brake mechanisms. With a decrease in load, the regulator reduces the fluid supply to the brake mechanisms until it is completely cut off, as a result of which the pressure in the rear brake drive decreases and the likelihood of the rear wheels locking before the front wheels locks up. As a result, slipping of the rear wheels and skidding of the car are prevented.

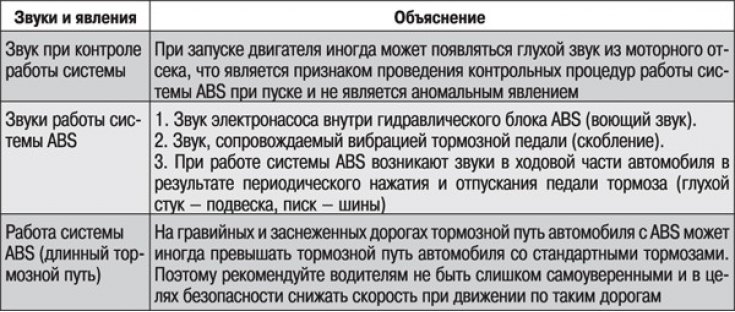

Sounds and phenomena that appear during the check and operation of the elements of the brake system, but are not abnormal, are given in Table. 14.1.

Table 14.1. Sounds and phenomena that appear when checking and operating elements of the brake system, but are not abnormal